The quest for building the next step in composite plug technology started with understanding the challenges experienced during the life of a composite plug. The composite plug operation has three stages: pump down, set & hold, and mill up. With focusing on the demands of the Plug & Perf operation rather than the design standards established 70 years ago, Rubicon developed the RzrFRACTM Composite Frac Plug. The RzrFRACTM delivers a 10,000 psi seal & anchor at 300F utilizing 100% composite material. And, the amount of material used is up to 70% less than the industry accepted alternative. With a view towards the three stages of a composite plug operation I’d like to highlight the features and benefits of the RzrFRACTM and the value it can bring to your operation.

A snag in the pump down operation can have broader ramifications to an operator’s ability to deliver their promised number of wells for the month or the quarter. Providing a tool that can operate in this well manufacturing environment without impacting the operation is paramount. During the pump down operation a composite frac plug is connected to a wireline setting tool and pumped into the well along with perforating guns. During this operation, the plug and the rest of the wireline bottom hole assembly (BHA) is expected to efficiently make its way to its designated location for setting. To get there the BHA is pumped with only .125” gap on either side through casing past sand and perforation debris. The composite plug assembly must operate reliably in this environment.

Rather than creating a seal with a traditional rubber element that is prone to swab or swell during pump down, the RzrFRACTM uses a proprietary non-rubber material. This material is designed specifically to expand up the cone and create a seal, but not respond to the fluid velocities experienced during pump down. This significantly reduces the risk of a preset.

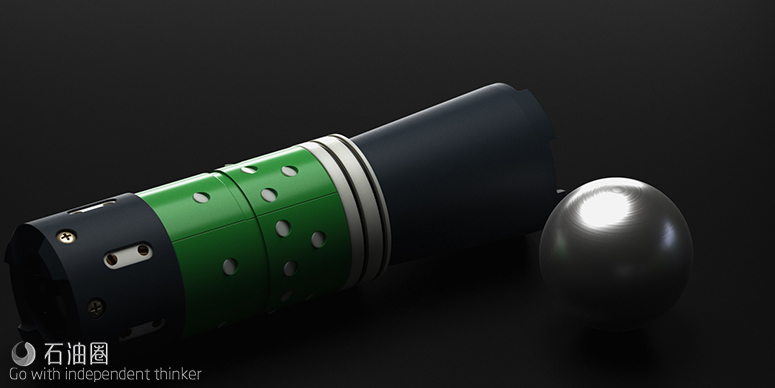

Most composite plugs, and packers for that matter, have slips that during setting break apart and ramp up a cone to interact with the casing. The slips are either a cast iron ring that is designed to break apart or separate segments that are held together with a metal or composite band. This shear mechanism is subject to tolerances, fatigue, or impacts. In most cases, if the shear media breaks the slips ramp up the cone and cause a preset. Unlike conventional technology the slips on the RzrFRACTM are not formed into a breakable ring, they are independent of each other and are captured on top and bottom to prevent movement during pump down. They are not subject to the risks posed by shear mechanisms.

Pumping past the sand and debris in the well can cause issues as well. The RzrFRACTM is a bottom set plug, which means the setting mandrel connected to the wireline BHA runs through the ID of the plug and connects to the bottom. If the plug encounters any impacts during the pump down operation the force exerted on the plug is immediately diverted into the setting equipment, significantly reducing the chances of an issue.

Finally, efficient use of water during the pump down operation is critical. Due to the geometry of the plug and the size of the ball our customers have seen savings of up to 40 bbl/plug.

Fundamentally we’ve designed the RzrFRACTM to significantly reduce the risk of the pump down operation while increasing the efficiency.

Though pump down and set & hold are very important in the performance of a composite frac plug, performance is largely measured by the mill up experience. This is largely due to the fact that you can put a number on the mill up: “How fast did they mill up?” Numbers make it easier to compare one product to another. The construction of the RzrFRACTM provides very consistent mill times averaging 3-5 minutes per plug. Several features contribute to such a quick and efficient milling operation.

First, the RzrFRACTM uses 70% less material than the industry accepted alternative. Just by selecting the RzrFRACTM for your 60-stage completion results in up to 1,000 lbs. less debris in your well. On an individual plug basis the RzrFRACTM has a large ID. This allows the outside of the mill, the most efficient portion, to interact with the bulk of the plug. Not only were we able to reduce the overall amount of material, we also reduced the amount of hardened material used to create the anchor. The RzrFRACTM uses just 24 small ceramic buttons, which break up into small pieces and leave your milling BHA virtually untouched.

Finally, the ball lands strategically on the plug such that the clutch mechanisms on the top and the bottom of the plug fully engage during the milling process. Many plugs have a ball that is sandwiched between the plug components from above and the plug below, during the milling operation. This ball can act as a bearing requiring higher weight on bit and longer mill times. With the RzrFRACTM this is eliminated along with any chance of spinning between the components during milling.

With the RzrFRACTM not only are individual plug mill times quick, consistent, and efficient the entire milling operation is optimized with shorter wash times and no need for short trips. Choosing the RzrFRACTM reduces the amount of debris in the well and the time it takes to remove it. And, the materials used significantly reduce the wear and tear on the milling BHA and eliminates the need for bit trips.

石油圈

石油圈