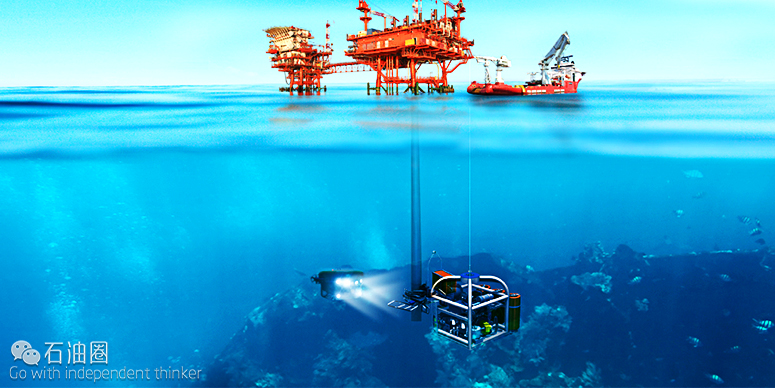

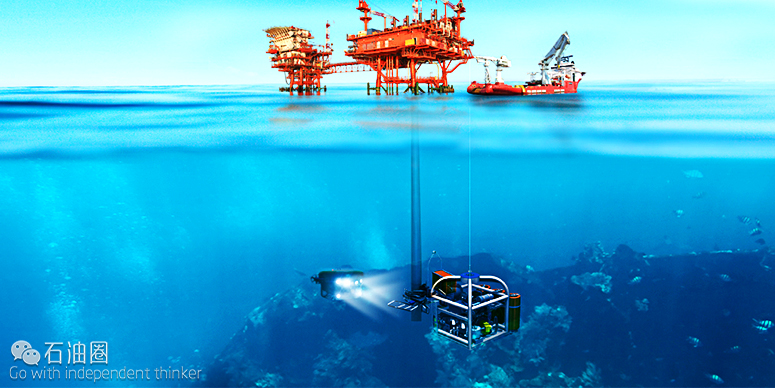

Chukar Waterjet公司在5月2-5号召开的休斯顿国际海洋技术博览会(OTC)上介绍了最新研发的SUB-JET 3000™ ROV(远程操控潜水器)技术设备,该新型设备携带动力源和多功能超高压(UHP)磨料水力射流系统,可下放至水深达3000米的深水环境进行切割作业,切割钢管壁厚可达250毫米。当射流压力达到390MPa时该设备可快速清除表面涂层、腐蚀带以及管柱海洋附生物。通常情况下,SUB-JET 3000™安置于一个可下悬设备且与ROV相联接,ROV的辅助动力源为设备提供所需动力。

100马力的SUB-JET 3000™系统每分钟可输出7.5升磨料水,压力高达390MPa。系统共携带35升体积的磨料,可支持30~90分钟的磨料射流切割作业。ROV通过液压油给射流增强器和相关工具提供动力,24伏直流电压(300瓦)作为控制电源,通过光纤数据线联接到顶部控制器。

系统满负荷运行需要每分钟供给150~200升的液压油,当ROV的液压油不够充分时,SUB-JET 3000™还可以在较低输出流量下开展作业,此情况下磨料水射流切割与涂层清除作业仍可开展,只是作业速率下降。SUB-JET 3000™系统甲板称重达500千克,其在水中所受浮力可抵消35升磨料重量。

在休斯顿国际海洋技术博览会期间,Chukar Waterjet公司还会一同展示C-JET 3000独立式的水下射流系统,该设备具备与SUB-JET 3000™系统相同的磨料水射流切割能力,与150马力的SHPU安置在一起且与具备其他功能的ROV系统相互独立。相比于SUB-JET 3000系统,多功能的C-JET 3000系统可通过潜水员或ROV开展作业。其作业性能与SUB-JET 3000基本相同:作业水深可达3000米,射流压力最高390MPa,支持30-90分钟的磨料射流切割作业。

相对于传统型水下切割清洁工具,Chukar Waterjet公司强力的水下磨料水射流切割系统作业更加安全、高效且具备多重优势,增强了操作者的作业灵活性并可承担更大型项目。不同于传统切割设备,水力射流系统设备切割作业中不会产生热量,降低作业期间气袋圈闭被点燃的风险。

Chukar Waterjet公司的水力射流设备可用于深水快速反应作业、打捞作业或者快速拆解作业,其可快速清除最“顽固”涂层,比如三层聚丙烯,还可更加安全、高效地切割多层套管。此外,它还可提供紊流流态的甲醇流体来开展水合物堵塞疏通作业。这项应用源于墨西哥湾漏油事件期间该公司被要求紧急研发一套系统设备,下潜至水下1500米疏通一个被堵塞的容载系统。

产品概述石油圈原创www.oilsns.com

- 电动马力可达150HP;

- 55kpsi/2超高压射流增强器;

- 作业水深可达10000英尺;

- 可实现远程控制作业;

- 设备尺寸:6”x6”x8”,重量<6300磅;

- 作业环境:海水、淡水、甲醇。

特性石油圈原创www.oilsns.com

- 8”厚重钢管

- 储油罐、管线、井口/立管

- 磨料射流清除水合物冰堵

- 磨料射流或旋转清洗管柱海洋附生物或其他覆盖物

应用石油圈原创www.oilsns.com

- 适用于弃置、打捞、检查、水合物堵塞疏通、清洁等作业

- 水下设备切割移除;

- 海底失事船只切割打捞;

- 磨料射流或旋转清洗以便隔离焊缝开展检查。

来自/Chukar Waterjet 译者/姚园 编辑/Lemon

SUB-JET™ ROV-ATTACHABLE WATERJET SYSTEM CUTS STEEL UP TO 250 MM THICK, BLASTS AWAY COATINGS AND CORROSION AT 3900 BAR

Chukar Waterjet, Inc. will unveil its new SUB-JET 3000™ ROV-attachable waterjet system at the OTC Offshore Technology Conference, May 2-5 in Houston. Look for Chukar in outdoor booth 546.

Chukar’s SUB-JET 3000 brings the power and versatility of ultra-high pressure (UHP) waterjet cutting and blasting to the deepwater subsea environment. Operable to 3000 meters, SUB-JET 3000 cuts steel as thick as 250 mm and quickly blasts away coatings, corrosion and marine growth at pressures up to 3900 bar. The SUB-JET 3000 is deployed as an underslung equipment skid on a work class ROV and is powered from the ROV’s auxiliary power.

The 100hp SUB-JET 3000 produces 7.5 liters per minute of 3900 bar ultra-high pressure water for cutting and blasting. It carries 35 liters of abrasive, providing 30 to 90 minutes of cutting time. The ROV provides hydraulic oil to power the waterjet intensifiers and operate attached tooling, 24 Vdc (300 watts) for control power, and a fiber optic data link to the topside controller. The system requires between 150 and 200 liters per minute of hydraulic oil to run at full capacity but can be operated at lower output if the auxiliary oil is not available from any given ROV. Cutting and coating removal are still effective at lower UHP output, only at slower throughput rates. The system weighs about 500 kg on the deck and is neutrally buoyant with 35 liters of abrasive.

In addition to the SUB-JET 3000, Chukar also will exhibit its C-JET 3000 standalone subsea waterjet system. The C-JET 3000 has the same cutting and blasting capabilities as the SUB-JET but is deployed independent of the ROV and is equipped with its own 150hp SHPU, freeing the ROV for other functions.

The versatile C-JET can be operated by a diver or ROV. Operable to depths up to 3000 meters (10,000 feet), the C-JET 3000 cuts steel up to 250 mm thick and blasts away coatings, corrosion and marine growth at pressures up to 3900 bar. Like the SUB-JET, the C-JET produces 7.5 liters per minute of 3900 bar ultra-high pressure water for cutting and blasting. It carries 35 liters of abrasive, providing 30 to 90 minutes of cutting time.

Chukar’s powerful underwater waterjet cutting and blasting systems improve the safety and effectiveness of subsea operations and have numerous advantages over conventional subsea cutting and cleaning tools, giving operators increased flexibility and access to larger projects. Unlike conventional tools, waterjet cuts without heat, reducing the hazard of igniting trapped pockets of gas during cutting. In addition, the tools used in a waterjet system cannot bind in the cut, jeopardizing asset integrity.

Chukar’s subsea waterjet equipment has numerous applications for deepwater emergency response operations, salvage operations, and rapid de-mobilization operations. Chukar systems quickly blast away even the toughest coatings, including three-layer polypropylene (3LPP), and provide a safer, more effective method for cutting multi-string casings for well severance. Waterjetting equipment also may be used to provide turbulence in a stream of methanol for hydrate remediation, an application Chukar developed in emergency response to the Gulf oil spill, when the company was asked to rapidly manufacture a system to clear a clogged containment system 1500 meters underwater.

PRODUCT OVERVIEW

- Surface-Powered 150HP Electric

- 55KPSI/2 GPM UHP Intensifier

- Operable to 10,000 ft. Depth

- ROV-Operable Tools

- Size: 6’x6’x8′; Weight: < 6,300 lbs

- Media: Seawater, Fresh Water, Methanol

ABRASIVEJET CUTTING

- 8″ Thick Steel

- Tanks, Pipelines, Wellheads/Risers

UHP WATERJETTING

- Blasting for removal of hydrate ice

- Blast or rotary cleaning for removal of marine growth and other coatings

APPLICATIONS

- Decommissioning, Salvage, Inspection, Hydrate Remediation, Cleaning

Application Examples:

- Cutting for removal of subsea structures

- Cutting for removal of subsea wrecks

- Blast or rotary cleaning to isolate welds for inspection

未经允许,不得转载本站任何文章:

-

- Demons

-

石油圈认证作者

- 毕业于中国石油大学(北京),化学工程与技术硕士,长期聚焦国内外石油行业前沿技术装备信息,具有数十万字技术文献翻译经验。如需获取更多技术资料,请联系Demons(QQ2582825239;微信15810965891)

石油圈

石油圈