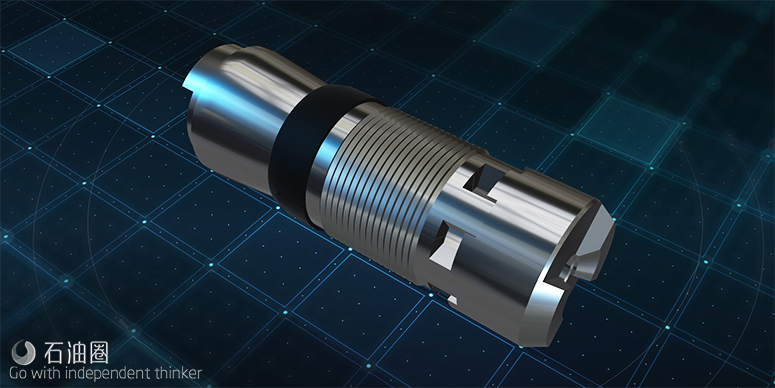

Lightweight frac plug reduces post-frac intervention time

Baker Hughes, a GE company (BHGE), has released its MILLITE lightweight frac plug, which “mills out more smoothly and cleans up better than any other conventional frac plug on the market, cutting costs and helping customers achieve first oil faster,” according to a company press release. Constructed completely of an engineered alloy material, the MILLITE plug does not contain any heavy metal or ceramic parts. The plug’s wear- and preset-resistant design virtually eliminates preset risks, enabling safe run-in rates in excess of 600 ft/min. A field-ready wireline adapter kit simplifies assembly, and the plug’s friction-slip anchoring system and packing element keep it firmly anchored in the casing at pressures up to 10,000 psi. The MILLITE plug mills more rapidly and more easily with less torque, helping to improve motor life and reduce drilling costs. With a specific gravity of 1.8, the plug’s fine debris can float up and out of the well without the aid of additional cleaning sweeps or costly chemicals. At under 13 in. long, its compact design also contributes to a lower overall volume of debris per plug compared to standard plugs.

Improved data-capturing system increases efficiency, reduces costs

Halliburton Co. has released its Cerebro in-bit sensor package, a new technology that obtains performance data directly from the drillbit and analyzes those data to optimize cutter engagement, reduce uncertainty and increase drilling efficiency, according to a press release. Cerebro provides an unprecedented view into an entire run by continuously capturing downhole vibration and motion data. This information helps operators pinpoint where bit damage occurred and when optimal performance is not achieved due to inconsistent design or operating parameters. The system identifies several common drillbit factors, including lateral and axial vibration, torsional resistance, whirl and stick/slip, which can negatively impact drilling speed and reliability. On a recent set of runs in the U.S. Midcontinent, Cerebro acquired information that allowed the operator to utilize a more aggressive cutting structure to increase drilling efficiency and reduce well time. These data also showed that higher drilling speeds could be used in softer sections of the well without vibration limitations.

New offering determines the effect of frac hits by using pressure-based technology

Reveal Energy Services has released its FracEYE frac hit analysis service, which is designed to expand the industry’s knowledge base about the critical issue of parent well-child well communication, a press release stated. With ongoing infill development, frac hits from the pressure communication between wells can cause significant production decreases in parent wells. Child wells also can underperform. The goal of the Reveal Energy Services’ R&D team was to clearly define the effect of frac hits and allow operators to make timely adjustments to their completion designs. The foundation of the FracEYE service is the company’s pressure based technology. The service categorizes the type and severity of interwell communication by measuring the pressure response from a parent well as hydraulic fracturing proceeds normally in child wells. A team of company geoscientists and completion engineers uses the pressure-response timing and geomechanics to classify the observed response into one of four categories: direct fluid transport, fluid migration, undrained compression and no signal.

Partnership targets hydraulic fracture characterization

C&J Energy Services is teaming up with Seismos to collaborate on a real-time hydraulic fracture characterization solution, according to a press release. The combined vision is to develop fit-for-purpose workflows that translate reservoir understanding into significant improvements in fracturing plans, field development and operational efficiency. The partnership will focus its initial efforts on the real-time quantification of the impact of various completion designs on stage performance, enabling them to adjust fracturing treatments on the fly. Leveraging C&J’s LateralScience geomechanical data, together with detailed fracture system measurements from Seismos, operators are able to understand and quantify the impact of various completion designs on stage performance.

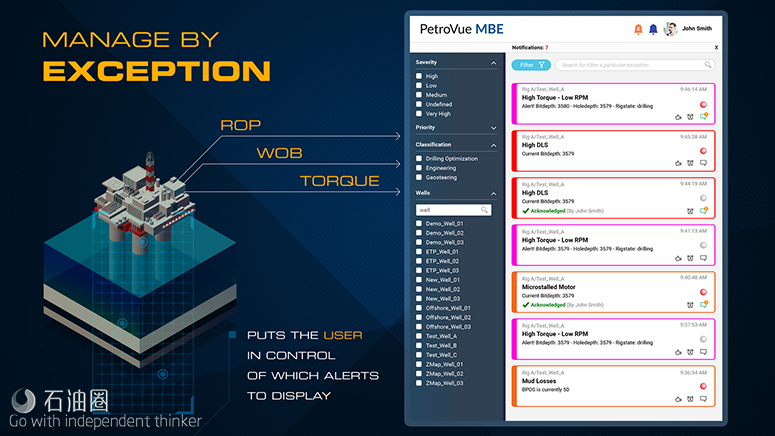

Smart alerting system for drilling operations helps eliminate alert overload

Petrolink has released its Manage By Exception (MBE) system, a software solution designed to help drillers manage the high volume of alerts generated during drilling by prioritizing them, thus enabling drillers to raise only the priority ones to exactly the right person at the right time, according to a company press release. Based on user-defined exceptions, MBE is a productivity enhancing system that puts the user in control of which alerts to display, thereby eliminating alert overload. MBE allows users to identify which wells and wellbores to monitor and enables them to send the corresponding alerts to selected personnel on the system. The system identifies initial issues before they become a problem, allowing operators to correct events in real time and ensure the integrity of their equipment. Users also have the flexibility to adjust rule or notification behaviors to adapt the system to a variety of critical real-time situations and well/wellbore scenarios. The system can monitor multiple workflows remotely across a fleet of rigs or implement companywide drilling activities and best practices on every active well. In addition to the onscreen notifications, the MBE system can send messages via text and email, allowing key personnel to continue their routines outside of the office while they are away from the computer.

Online ROVs marketplace flags opportunities

ROVHUB has launched the first online marketplace for ROVs, the company said in January. Founder David Gault said he developed ROVHUB after seeing ROVs lying idle during the 2014 oil and gas downturn. “The oil and gas market is picking up, but there is still spare ROV capacity,” he said. “ROVHUB can flag up alternative opportunities for owners outside their core regions and in other sectors such as renewables and aquaculture.” Gault added that the service makes other industries aware of oil- and gas-focused ROVs that might be available for their work. ROVHUB took two years to develop and boasts thousands of ROVs and hundreds of ROV companies in its database. Gault considers it a component of a digital trend in the marine and offshore industries. “Adoption of digital technologies is gathering pace in the oil and gas industry,” he said. “It’s not just about cost-cutting, it’s also about automating manual processes to free up resources that can be used more effectively elsewhere, and it’s creating opportunities by doing things differently.”

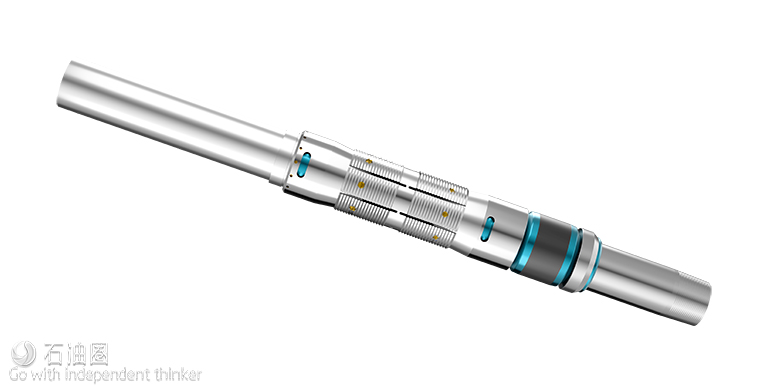

New liner top packer can withstand high differential pressures

National Oilwell Varco (NOV) has released its new MSF liner top packer for hydraulic multistage fracturing to its portfolio of completion tools and technologies. Rated to 10,000-psi differential pressure and a maximum operational temperature of 300 F, the new liner top packer is qualified to the rigorous standards of American Petroleum Institute 14310 V3. The system is designed specifically for the challenges of horizontal hydraulic multistage fracturing completions, and it can withstand high differential pressures and heavy tubing loads during stimulation. The slips, designed with nearly fully circumferential contact with the casing, ensure that the system will perform under stimulation pressures even in high-yield grades of casing. In addition, a one-piece sealing element helps to avoid swabbing and enables the higher circulation rates required to maintain hole cleanliness during deployment of the liner.

Software estimates geomechanical logs, pore pressure, stresses and natural fracture

FracGeo has released its software module DrillPredictor, which is a cloud- and subscription-based web service designed to put completion optimization in the hands of any unconventional reservoir operator, a press release stated. The technology uses commonly available surface drilling data from any contractor to provide the information needed to adapt any frac treatment to the variable subsurface geologic and geomechanical conditions. DrillPredictor uses FracGeo’s Corrected Mechanical Specific Energy (CMSE), which accounts for frictional losses along the wellbore for any type of drilling equipment including rotary steerable systems and mud motors. FracGeo’s CMSE is used to compute unique products, such as pore pressure, stresses, natural fractures and geomechanical logs along the wellbore. These logs are then used immediately after drilling the well to provide multiple completion optimization strategies that are quantified with an estimated cluster efficiency, followed by the propped fracture geometry and the resulting depletion using FracGeo’s advanced and fast frac design and reservoir simulation technologies. These estimations are validated with fiber optics, microseismic moment tensor inversions and production logs.

Scientists create new oil-resistant filter technology

Crude oil is sticky stuff and often clogs filter membranes and other equipment used in the oil and gas industry. Scientists at the U.S. Department of Energy’s Argonne National Laboratory have developed a novel, patent-pending approach that will prolong the lifetime of key industrial equipment. The new invention consists of water-loving, oil-repelling thin film coatings on the surface of filter membranes. These metal oxide coatings grab onto any loose water molecules while resisting oil. Fouled membranes can be a costly hassle for the oil and gas industry. For instance, replacing clogged filters during hydraulic fracturing often requires shutting down equipment. Oil-resistant membranes could significantly reduce the need for both filter replacement and downtime. Also, Argonne’s atomic layer deposition process keeps membranes from clogging during hydraulic fracturing to better filter the water passing through them, allowing operators to reuse water. This could be a direct replacement for filter units in use today. The method also could help in oil spill cleanup efforts. Pipe and container surfaces treated with the oxides could just be rinsed clean. anl.gov

New AI technology to accelerate projects

BP Ventures has invested $5 million in Belmont Technology’s Series A financing to further bolster BP’s artificial intelligence (AI) and digital capabilities in its upstream business, according to a company press release. Belmont, a Houston technology startup, has developed a cloud-based geoscience platform using AI that has a string of unique capabilities, including specially designed “knowledge-graphs.” BP experts feed the platform geology, geophysics, reservoir and historic project information. Then the platform intuitively links that information together, identifying new connections and workflows and creating a robust knowledge-graph of BP’s subsurface assets. Much like data searches available in the consumer domain, BP experts can then interrogate the data, asking the powerful knowledge-graph specific questions in natural language. The technology then uses AI neural networks to interpret results and perform rapid simulations. Aimed at accelerating project life cycles, from exploration to reservoir modeling, the technology is targeting a 90% time reduction in data collection, interpretation and simulation, the release stated.

Biodegradable subsea equipment preservation fluid

Universal Subsea Inc. (USI) has released an environmentally friendly subsea equipment preservation fluid called Defender Stasis LT, a press release stated. The lightweight, nontoxic and biodegradable preservation fluid provides long-term protection for subsea equipment components and interface profiles. The fluid is compatible with all commonly used metals and nonmetallic materials in oilfield service. Defender Stasis LT is ideal for subsea equipment preservation use to protect the internals of subsea trees, subsea manifolds, jumpers and flowlines during shipping, storage or wet parking. The preservation fluid meets and, in some cases, far exceeds requirements and strict regulations for offshore drilling fluids discharged to sea. “Defender Stasis LT is the first subsea wellhead preservation fluid that meets regulatory requirements for 24-hour per day use in offshore oil-producing countries worldwide,” said Sean Thomas, P.E., general manager at USI. The fluid is rated as a fire-resistant hydraulic fluid because of very low volatility with a high flash point and high fire point. The fluid has negligible toxicity in the event of personnel exposure and is rated as a negligible hazard or minimally toxic for all personnel ratings. In addition, Defender Stasis LT is recyclable and can be reprocessed to its original specifications. For shipping or storage applications where the preservation fluid is recovered after use, customers can choose to recycle the fluid rather than pay for disposal costs. universalsubsea.com

Perforating system packs high charge performance and short footprint

Hunting Energy Services has developed the shortest plug-and-play perforating gun system capable of firing up to four shots per 7.5-in. cluster, according to a company press release. The H-2 Perforating System features EQUAfrac shaped charges in a single plane configuration, creating the shortest gun length on the market. H-2 simplifies loading and arming by utilizing proprietary charge puck and Shorty ControlFire cartridge technology to eliminate a detonating cord. The H-2 system is ideal for high gun per stage operations and scenarios where rigup length is limited. H-2 will be available in a 31?8-in. gun diameter. H-2’s shaped charges require no detonating cord and are easily pushed into place on the charge puck, making loading as easy as pushing a button. Field trials with major U.S.-based operators were scheduled to conclude in February and commercial availability is scheduled to begin in March. A 33?8-in. gun diameter version will follow in the third quarter.

石油圈

石油圈