At Subsea Valley 2017, Jan-Fredrik Carlsen, CEO of the Notodden based Norwegian company Optime Subsea, boldly promised to revolutionize the intervention and controls segment of the subsea oil and gas industry through a new and disruptive technology

A year later at Subsea Valley 2018, the promise has been delivered by presenting Optime’s Subsea Controls and Intervention Light System (SCILS).

Optime Subsea AS (“Optime”) is headquartered in Notodden, Norway, with operations out of Houston Texas, USA. It is a smaller organization, specifically targeting innovative solutions that deliver cost-savings to customers in their niche controls and intervention market.

“Our intent is not to be disruptive for the sake of being disruptive, but support the industry’s progress in providing cost reducing tecnology. I believe our SCILS demonstrates this. We identified an area in the industry which was just neglected, perhaps for good reasons, but we identified it, solved it and now delivered on it. This is truly the smallest and most cost efficient tree control and intervention system available. The SCILS is similar to an Intervention Workover and Completion System (IWOCS) used for subsea well-access. There is however currently no other system capable of operating on any type of tree at 3000-meter depths, and yet small and light enough to be literally mobilized from the bed of a pickup truck, which was actually done when transporting the SCILS to the Subsea Valley conference this year,” says Jan-Fredrik Carlsen.

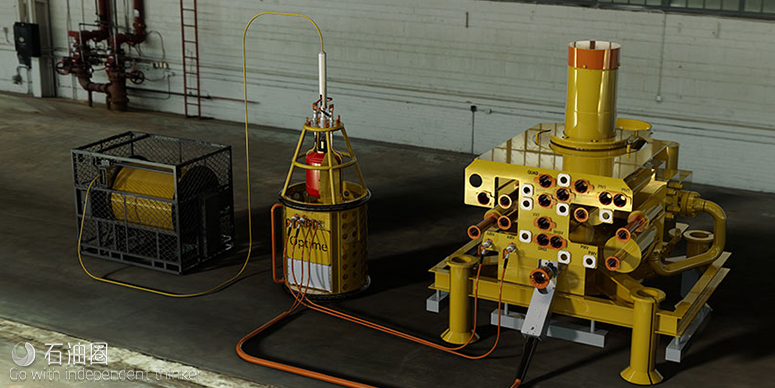

The SCILS measures 1.8 meters in diameter, 2.2 meters in height and weighs 3 metric tons. The traditional IWOC system comes with a 20-foot topside container and a large reel and umbilical, weighing approximately 50 metric tons. The size reduction of the SCILS is a result of transferring the hydraulic power subsea, using Optime’s subsea pumps, rather than through a topside umbilical.

“When compared to traditional solutions, the SCILS provides immediate cost savings for operators. We require 2 resources in operation, current systems need 6 to 8. Safety is increased and the SCILS can be mobilized and demobilized in a single day, in contrast to today’s solutions taking weeks. We are now in the process of getting the SCILS operational and with the ability of deploying this from any type of vessel, realize that our customer base increase substantially compared to current systems. With this unique solution, we do believe that we are going to be the preferred provider globally for IWOC systems. It is so cost efficient and built on technology which have taken years to develop, so that others don’t need to. We can support service providers, system developers and operators in being a reliable provider of IWOCS, ” Jan-Fredrik concludes.

The Subsea Controls & Intervention Light System (SCILS) designed to simplify well access, well interventions and work over operations from any type of vessel. Unlike traditional Installation Workover Control Systems (IWOCS), the SCILS is able to carry out multiple well control operations without adding complex and heavy equipment. The system comes with a closed loop hydraulic control system. The relocation of hydraulic power to the seabed eliminates the need for large equipment, long lead times, reliability challenges, complexity in operations and the high cost that may be found in traditional topside hydraulic umbilical systems. With a universal interface, light and small size, the SCILS removes the need for time consuming and costly mobilizations and demobilizations. Combined with a high efficiency and increased functionality, the SCILS ultimately delivers lower CAPEX and OPEX across the operations – benefiting everyone.

The following well installation and work over operations are all optimized through the use of SCILS: FROM VESSELS

- XT (“Christmas Tree”) Installation – Installation & functional testing of subsea

- XT Testing – Follow-on testing & diagnostics for installed subsea trees • XT/PRT (Plug Retrieval Tool) Control – Control of the XT/PRT during VXT installation or PRT operations

- LWI (Light Well Intervention) XT Control – Control of the XT for LWI operations, including intervention and full P&A (Plugging & Abandonment)

- XT SCM (Subsea Control Module) Testing & Diagnostics – using electrical downline umbilical only

- Manifold Control & Functional Testing

- Hydraulic Intervention – Well stimulation

FROM RIGS

- XT installation – full testing capability

- XT Installation – Installation & functional testing of subsea trees, both HXT and VXT

- HXT Completion Control – Control of HXT’s during completion operations on HXT’s having no UDF (Umbilical Disconnect Function) on the BOP (Blow Out Preventer)

- XT control during completion (HXT systems, i.e. no UDF system on BOP)

- XT control during work operation, open water riser systems

SCILS options

Skid with reel for hydraulic jumper:

This skid has incorporated reel for a 16 lines hydraulic jumper to XT interface. This reel have 50 meter capacity and will spool in the jumper controlled from the SCILS controls

Skid with basket for hydraulic jumper:

This skid has traditional basket for XT jumpers and is provided as a standard skid offering for the SCILS. The skid has ROV panel for installation of any 3rd party MQC plates

Hydraulic intervention skid:

This skid allows for well stimulation. It has connection for hose or coil tubing to perform well stimulation from vessel. The skid has two 2” gatevalves that will shut in by signal or disconnect. With this skid, SCILS control the fail-safe valves and potentially XT if required. Larger bore/valves can be provided if needed

石油圈

石油圈