Intelligent Completion Packoff Element

Our intelligent completion packoff element is a retrievable and hydraulically set device that provides zonal isolation for completions that require line bypass. With a one-piece body, the packoff element makes it possible to feed multiple lines—for gauges, chemical injection, and other systems—through it in either a workshop or offshore environment.

The Weatherford intelligent completion packoff element (ICE) is a retrievable and hydraulically set multiple control-line bypass that achieves zonal isolation within intelligent well completions. The onepiece body makes it possible to feed multiple lines through the ICE tool in either workshop or offshore environments. The feedthrough capabilities also enable placing gauges and chemical injection systems below the completion isolation system.

Tested in accordance with the International Organization for Standardization (ISO) 14310, the ICE tool provides multiple setting options. Control-line pressure, a mechanical communication sub, or a radio-frequency identification (RFID) enabled communication sub can set the base packer. The ICE tool is released into a retracted position using a straight-pull, shear release.

RFID Optibarrier™ Ball Valve

Our Optibarrier ball valve controls wellbore flow. The tubing-mounted, bidirectional ball valve is opened and closed remotely using RFID-enabled hydraulic control modules. It can also be opened mechanically using industrystandard shifting tools or a stinger module in the upper-completion system.

The Weatherford Optibarrier ball valve is a tubing-mounted bidirectional ball valve that can be opened and closed remotely using a radio-frequency identification (RFID) enabled control module. It can also be opened mechanically using industry-standard shifting tools or a stinger module assembled into an upper completion or workstring.

Tested beyond the International Organization for Standardization (ISO) 28781-V1 standards and in accordance with the American Petroleum Institute (API) specification 19-V, the bidirectional sealing mechanism provides a reliable downhole barrier. When open, the fullbore ID maximizes flow area and enables access to the formation. The ball valve can be manufactured in a variety of metallurgies, ranging from basic 4140 to high-nickel premium alloys.

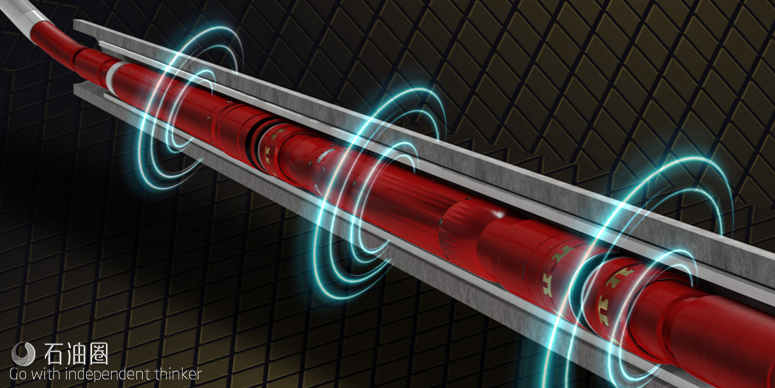

RFID Inflow Control Device

Our RFID inflow control device (ICD) evenly distributes inflow throughout a horizontal wellbore. The ICD also reduces water or gas production, improves reservoir drainage, and enhances sand control. The device is customizable to customer-specific applications and can be opened by either circulating RFID tags, using a frequency modulated pressure signature, timer or a combination of these.

The Weatherford RFID inflow control device (ICD) combines the FloReg™ inflow control system with RFID technology to evenly distribute inflow throughout a horizontal wellbore. The ICD, or a series of ICDs, are run closed and then, at depth, sequentially opened with no intervention. This capability eliminates the need for washpipe, intervention services, wires, or control lines, which reduces completion time and risk. The ICD is customizable to customer-specific applications, and it can be opened by either circulating RFID tags, using a frequency modulated pressure signature, timers, or a combination of these.

Designed with debris, mud solids, and cement in mind, the device does not rely on debris-sensitive springs, check valves, or complex piston arrangements. Further, reliability is not compromised by the need for any pre-charged or well-sensitive piston chambers.

RFID Reservoir Isolation Valve

Our RFID reservoir isolation valve is an interventionless barrier device that isolates the toe of the completion, which eliminates the need for a deep-set plug. Inside the valve, a patented fall-through-flapper provides a bidirectional barrier. When remotely opened, the flapper releases any debris, mud solids, and cement and leaves a flush bore. The tool also features a ceramic flapper option as applicable.

Tool Description

The Weatherford RFID-operated reservoir isolation valve (RIV) is an interventionless barrier device that isolates the toe of the completion, which eliminates the need for a deep-set plug and reduces completion time and risk. Qualified according to the International Organization for Standardization (ISO) 28781 V1, the RIV is a cost-effective and safe means of isolating completion systems.

The robustly constructed RIV is designed with debris, mud solids, and cement in mind; the internal operating mechanism is contained with the flow path. The debris-tolerant RIV does not rely on debrissensitive springs, check valves, or complex piston arrangements.

Built on patented fall-through-flapper technology, any debris fill is relieved and released as the flapper opens down into its housing to leave a flush bore. The flapper also provides a bidirectional barrier against which the completion system can be tested and hydraulically set. The tool also features a ceramic flapper option, as applicable. The RIV is run in the open position and is closed by circulating RFID tags via a preprogrammed timer. The RIV can be reopened by a frequency modulated pressure signature

石油圈

石油圈