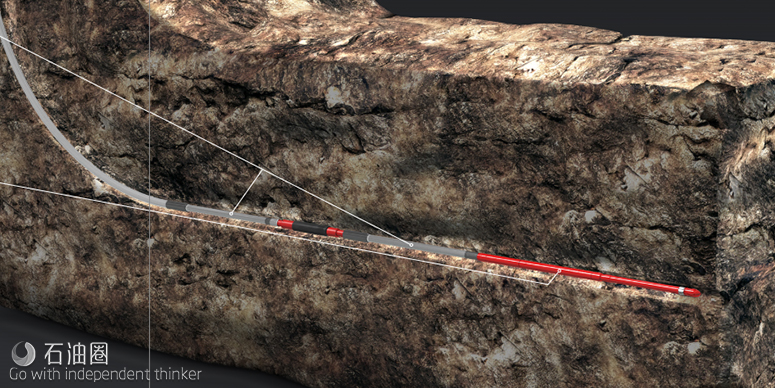

The world’s first and only remote-activated, single-trip deepwater completion system delivers greater efficiency, flexibility, and reward high rig costs drive the need for reduced trips in hole, particularly in deepwater environments. The ability to perform multiple operations in less time and with fewer equipment and personnel requirements sets the stage for dramatic, tangible benefits.

The Weatherford TR1P single-trip completion system establishes a new precedent in completion installations. By enabling you to install the upper and lower completion in just one trip, the system simplifies your operations and reduces your completion installations times by as much as 40 percent.

This game-changing deepwater solution overcomes the barriers to adopting single-trip systems by combining radio-frequency identification (RFID) technology and elements from our premium completions technologies into one. The result is a completion system that eliminates the need for control lines, wash pipe, wireline, coiled tubing, and workover rigs for a 100-percent interventionless operation that reduces deployment risks. The remote, intervention-free capability of the system further enables you to perform the operations demanded by your reservoir—rather than your budget—in both producer and injector wells.

INCREASE EFFICIENCY TO REDUCE COSTS

We help you to do more in less time. Compared to conventional mechanical or hydraulic completion equipment, the TR1P system delivers real savings to overall operational and rig spread costs. Using RFID technology, the system lets you activate your tools an unlimited number of times—without requiring you to pull out of the hole—and can reduce completion installation times by as much as forty percent.

THE FIRST AND ONLY PROVIDER OF RFID-ENABLED DOWNHOLE TECHNOLOGY

Weatherford is the sole provider of RFID-enabled downhole tools. We pioneered the use of this proven technology to expand your capabilities and deliver real business benefits in the oilfield, not only in drilling and cementing operations but also in completions. The TR1P system incorporates RFID completion tools with a decade of successful activations.

MANAGE RISKS AND MAXIMIZE REWARD

We help you to manage risk and maximize reward. By minimizing the number of trips in the hole, the TR1P system reduces total operating hours and exposure of field personnel. Although the system is fully interventionless, it retains mechanical contingencies to further manage risks. The TR1P system eliminates major wellbore and through-tubing interventions, de-risks the installation operation, and improves well control. All of this means engineering and technological excellence throughout the well life cycle for a reduced total cost of ownership.

ENHANCE OPERATIONAL FLEXIBILITY AND CONTROL

We bring the power of control and flexibility to your wellsite. The TR1P system lets you control multiple RFID-enabled tools in a single string and selectively target and actuate individual tools as needed. By using RFID for activation, the TR1P system also eliminates control lines, wash pipe, wireline, coiled tubing, and workover rigs. The system will not interfere with wireline or coiled tubing operations. It also allows use with conventional mechanical or hydraulic tools—regardless of where they are placed.

THE SINGLE-TRIP COMPLETION SYSTEM AT A GLANCE

RFID OptiROSS® Remotely Operated Sliding Sleeve

The RFID OptiROSS remotely operated sliding sleeve remotely manages flow from individual production zones, with no limit to the number of sleeves that can be installed in a single monobore completion. The tool is preprogrammed to operator-specific applications and is opened and closed by circulating RFID tags, frequency-moderated pressure signatures, timers, or a combination of these.

The Weatherford OptiROSS remotely operated sliding sleeve combines advanced well sliding-sleeve technology with RFID technology to provide an interventionless, control-line-free well management device. The tool provides remote means of managing flow from individual production zones with no limit to the number of sleeves that can be installed in a single monobore completion.

The tool is preprogrammed to operator-specific applications and is opened and closed by circulating RFID tags, frequency-modulated pressure signatures, timers, or a combination of these. The debristolerant tool does not rely on any debris-sensitive springs, check valves, nor complex piston arrangements during operation; thus, its reliability is not compromised by the need for precharged or wellsensitive piston chambers.

OptiPkr™ Production Packer

Our OptiPkr production packer combines the robust performance of a permanent packer with the flexibility of a retrievable packer. The packer provides a VØ-rated, gas-tight seal between the outside of the production tubing and the inside of the casing. The modular design adapts to most applications and wellbore conditions, and it lets you convert between hydraulic-, hydrostatic-, and RFID-setting modes.

The Weatherford OptiPkr production packer combines the robust performance of a permanent packer with the flexibility of a retrievable packer into one tool. It provides a reliable seal between

the outside of the production tubing and the inside of the casing in demanding wellbore conditions. The packer has a modular design that adapts to most applications and wellbore conditions and enables conversion between hydraulic-, hydrostatic-, and RFIDsetting modes. It exceeds the International Organization for Standardization (ISO) 14310 Level V0 standards for load and pressure.

Optimax™ Tubing-Retrievable Safety Valve

With more than 200,000 cumulative years of service, our Optimax tubing-retrievable safety valve is backed by the highest reliability record in the industry. This rod-piston, curved-flapper type safety valve shuts in the well with a gas-tight seal in the event of uncontrolled flow caused by equipment failure or damage. A single hydraulic control line operates the valve: applying pressure opens it, and bleeding off pressure closes it.

The Weatherford Optimax series WSP(E) tubing-retrievable surfacecontrolled subsurface safety valves are rod-piston, curved-flapper type safety valves. These valves are installed to shut-in wells in the event of uncontrolled flow caused by equipment failure or damage. An integral part of the completion string, each model is controlled by a single hydraulic control line. Control-line pressure keeps the valve in the open position; when pressure is bled off, the valve closes to prevent uncontrolled flow. In the unlikely event the safety valve malfunctions, the Weatherford Optimax WLT lockout tool and Optimax WCT control-line communication tool can be deployed to adapt the valve to accept a Weatherford WIT wireline-insert safety valve, which minimizes disruption to production operations.

Intelligent Completion Packoff Element

Our intelligent completion packoff element is a retrievable and hydraulically set device that provides zonal isolation for completions that require line bypass. With a one-piece body, the packoff element makes it possible to feed multiple lines—for gauges, chemical injection, and other systems—through it in either a workshop or offshore environment.

The Weatherford intelligent completion packoff element (ICE) is a retrievable and hydraulically set multiple control-line bypass that achieves zonal isolation within intelligent well completions. The onepiece body makes it possible to feed multiple lines through the ICE tool in either workshop or offshore environments. The feedthrough capabilities also enable placing gauges and chemical injection systems below the completion isolation system.

Tested in accordance with the International Organization for Standardization (ISO) 14310, the ICE tool provides multiple setting options. Control-line pressure, a mechanical communication sub, or a radio-frequency identification (RFID) enabled communication sub can set the base packer. The ICE tool is released into a retracted position using a straight-pull, shear release.

石油圈

石油圈