ZetaFlow Sand-Conglomeration Services can increase maximum sand-free flow rates, reduces fines migration and boosts total reservoir performance.

Effective and efficient sand control

Enhance flow rates and protect your reservoir with ZetaFlow® sand-conglomeration services

Sand problems will eventually plague most wells. Whether beginning with first production or with water breakthrough, sand and unconsolidated particles can erode the near-wellbore area and slowly choke production.

ZetaFlow sand-conglomeration technology is field-proven to dramatically improve sand management and enhance production. This chemical process increases the attraction between particles without damaging the reservoir by trapping formation sand and fines to maximize sand-free flow rates and increase production.

Effective in most formation types, including sandstone, coal, and shale, the unique ZetaFlow chemical solution controls the movement of formation sand and fines that hinder production flow. It enhances the load recovery of treatment fluids during fracture flowback operations. The ZetaFlow solution modifies the zeta (ζ) potential of the formation or proppant surfaces and of the fines and brings them to near-neutral values.

Tool Description

The ZetaFlow agent is compatible with many formation types including a variety of sandstones, coals, and shales. By modifying the zeta potential of proppant surfaces and bringing them to near-neutral values, the ZetaFlow agent increases the potential for particle agglomeration and aligns the proppant to enhance the conductivity of the proppant pack.

The agent achieves sand and fines control in a similar manner: treating formation particles with the ZetaFlow agent minimizes the zeta potential of the sand and fines to promote particle agglomeration. This process fixes potentially production-damaging particles in place without restricting production flow. The unique chemistry of the ZetaFlow agent leaves the formation less hydrophilic and in the optimal wetted condition for increased load recovery.

The ZetaFlow agent can be deployed on the fly in slickwater, linear-gel, and borate crosslinked-gel applications by continuously adding the solution at a constant loading level. The amount of ZetaFlow agent needed depends on the quantity of proppant. Proper chemical loadings for remedial cleanup treatments are engineered to the specific application.

How the ZetaFlow service works

The ZetaFlow service resolves existing and potential sand problems that reduce production. Though some wells begin production with sufficient natural consolidation with clays, reservoir depletion or water breakthrough dissolves the clays or changes the capillary pressure, which triggers sand production.

ZetaFlow solution alters the ζ-potential of the formation. The solution is added continuously in both slickwater and borate cross-linked gel systems that are engineered for the specific application. It minimizes the ζ-potential of sand, proppant, or fines to promote particle agglomeration, which enhances sand- and fines-free production.

The ZetaFlow service features

•Can be used in place of curable resin-coated proppants

•Controls the migration of damaging fines to optimize production

•Leaves the formation in the optimal wetted condition

•Can be added to stimulation fluid on the fly during fracturing or sand-control operations

•Enhances the load recovery of treatment fluids

•Is easy to use

The ZetaFlow service advantage

• Controls formation sand and fines movement

• Maximizes asset value and reduces lifting costs by increasing sand-free rate

• Enhances standalone screen, gravel-pack, and frac-pack applications

• Minimizes erosion of the near-wellbore area

• Adapts to changing reservoir stress conditions by remaining ductile and agglomerative

•Provides an effective, cost-efficient, and nondamaging alternative to resin-consolidation treatments

• Replaces traditional, curable, resin-coated proppants

• Can be deployed via coiled tubing or production tubing

Physical Properties

Appearance:Clear, dark liquid

Density:8.59 to 8.76 lb/ga

Specific gravity:1.03 to 1.05

pH:5.7 to 6.9

Flash point:88.3°F (31.3°C)

Ionic charge:Cationic

Solubility in water:Dispersible

Freeze point:–49°F (–45°C)

Applications

Slickwater, linear-gel, and borate crosslinked-gel fracturing operations

Case study

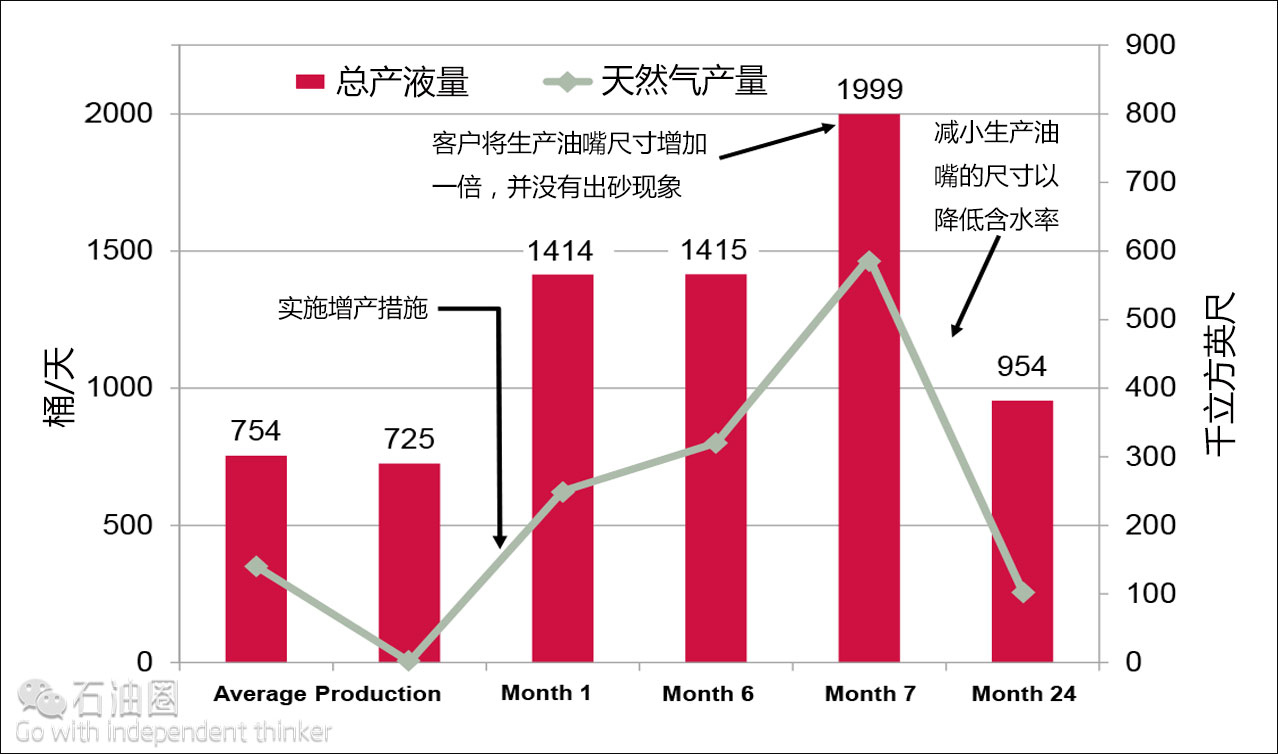

Case study 1: ZetaFlow sand-conglomeration service increased revenue by $1million in just 6 months

An offshore Gulf of Mexico well produced increasing volumes of sand, which made production uneconomic. Once the ZetaFlow service was performed, the well recorded a 78% increase in its maximum sand-free flow rate despite increasing the choke size.

The operator’s investment was recouped in less than 30 days, with an incremental increase in revenue of approximately US $1 million in the first 6 months. The production increases have been maintained for nearly a decade, with zero sand to date.

Case study 2: ZetaFlow® Chemical Additive Restores Production to 105 BOPD in Sandy, Scale-Prone Well

LOCATION:Rionegro, Santander, Colombia

WELL TYPE:Onshore, oil

HOLE SIZE:8-1/2 in.

CASING TYPE AND SIZE:7 in., 26 lb/ft, N-80, BTC conn

TUBING TYPE AND SIZE:3-1/2 in., N-80

RESERVOIR TEMPERATURE: 170°F (77°C)

RESERVOIR PRESSURE:1,683 psi (11.6 MPa)

TOTAL DEPTH:8,500 ft (2,591 m)

SECTION TREATED:8,475 to 8,492 ft (2,583 to 2,588 m)

Approach

• Weatherford designed a custom treatment plan using chemical additives compatible with the hostile characteristics of the formation fluids, which included a high tendency to form calcium-carbonate scales.

• On-site stimulation specialists performed an organic-based pre-flush to clean the perforations.

• The team deployed the ZetaFlow chemical additive to provide fines control. They controlled drawdown during treatment and verified pressure using a downhole sensor. After the treatment, drawdown was maintained at 170 psi (1.2 MPa).

• The well resumed production at an average rate of 170 BOFD (27 m3/d) and 105 BOPD (17 m3/d) with a 38% basic sediment and water cut.

Value to Client

• Restore production on a scale-prone well that was shut in because of sand infiltration. The operator had performed five previous well-cleaning interventions, but sand infiltration recurred each time and halted production within 7 days.

• The well continues to produce at a rate of 105 BOPD (17 m3/d) with zero sand and fines migration problems.

• In addition to restoring production, the ZetaFlow additive reduced the sediment and water cut from 50% to 38% in the two months following the treatment.

• Optimize drawdown pressure. The sand-control treatment enabled the operator to reduce drawdown 85% from 1,150 to 170 psi (7.9 to 1.2 MPa).

石油圈

石油圈