NOV’s VectorZIEL™ and VectorEXAKT™ rotary steerable systems (RSS) have a legacy of proven performance over the last 30 years, dating back to their initial application of drilling deep vertical mine shafts with high precision. The VectorZIEL and VectorEXAKT systems have been developed by a dedicated engineering team in Germany to provide industry-standard steering performance in vertical, directional, and horizontal applications.

The systems are available for all common hole sizes, while providing several benefits, including:

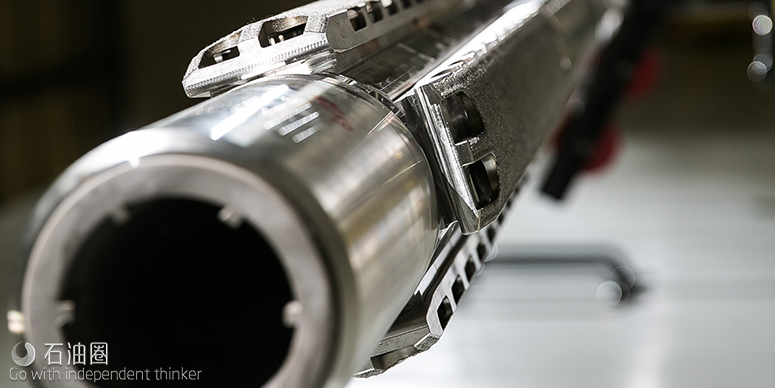

- Short, nonrotating sleeve design with four steering ribs for accurate directional control even under severe stick-slip conditions

- Near-bit inclination, azimuth, and gamma measurements, providing both continuous and static surveys at only 3 ft (1 m) from the bit

- Integrated mud generator and mud pulser enable a short, integrated tool design with low operating costs

- Closed-loop trajectory control provides automated build, turn, and hold capabilities with limited interaction from surface required

The VectorZIEL and VectorEXAKT systems feature industry-leading Tolteq™ mud pulsers and can be combined with NOV’s symmetric propagation resistivity LWD tool for additional real-time formation evaluation measurements. Available for purchase and supported by NOV’s global R&M infrastructure, these tools allow independent directional drillers to provide top-tier directional services in the global marketplace.

In the rental market, the VectorZIEL and VectorEXAKT systems have been used to drill more than 230,000 ft (70 000 m) in more than 55 wells around the world. Additional wells have been drilled using the 40-plus customer-purchased tools. More than 50% of the rental runs with the VectorZIEL and VectorEXAKT systems have been for more than 200 circulating hours in duration, demonstrating the tools’ robust design.

Our VectorEXAKT vertical rotary steerable system (RSS) is designed for high performance in vertical drilling operations. The VectorEXAKT system is set apart by its high rate of penetration, precise verticality control, and robust design.

Description

The VectorEXAKT RSS stays on course through continuous steering—when there is a deviation from vertical, the system will autonomously steer back on course. You can also run the VectorEXAKT system below a motor for performance drilling applications.

Features/Benefits

Integrated MWD system

- Provides real-time feedback while drilling Near-bit inclination and gamma measurements

- Delivers directional and geological information within 4 ft of the bit Closed-loop vertical control that requires no intervention from surface

- Steers and maintains a vertical hole autonomously Can be combined with NOVs MWD and LWD tool portfolio

- Allows the construction of a fully integrated drilling and logging BHA Short non-rotating housing with four steering ribs

- Provides accurate vertical control even under severe stick-slip conditions

We are pleased to announce the first commercial run for our Vector rotary steerable system (RSS) in the Middle East/North Africa (MENA) region. While drilling in a hard, interbedded formation with significant dips, our client needed to drop from 2.5° and hold vertical for the remainder of the well.

Our VectorEXAKT™ 800 RSS was integrated into the BHA, and a single tool drilled the entire 12¼-in. section in two bit runs. The VectorEXAKT RSS immediately reduced casing-shoe inclination from 2.6° to vertical and maintained verticality within 0.1° for the entire 3,028-ft (923-m) section until target depth was reached. With access to our VectorEXAKT tool, our client can now expand their service offerings to include vertical RSS drilling services for large-diameter boreholes.

“We are thrilled to complete the first run of our Vector RSS tools in the important MENA region,” said Andrew Craig, Managing Director for Directional Measurement and Steerable Technologies. “NOV has made a significant investment in developing a portfolio of RSS tools that meets the needs of today’s drilling challenges. We are excited that making this critical technology available to the market will enable our customers to grow their directional capabilities.”

Our VectorEXAKT 800 RSS delivers higher ROP and precise directional control in vertical or inclined boreholes. This integrated drilling and measurement tool incorporates an inclination survey package within 5 ft of the bit, along with a pulser to deliver real-time data transmission. Visit our VectorEXAKT RSS product page to learn how you can steer your operating costs in the right direction.

VectorZIEL Rotary Steerable System

Smart Drilling GmbH is now part of NOV and the RSS tools are now offered through NOV ReedHycalog as the VectorZIEL and VectorEXAKT products – formerly known as the Smart Drilling Scout and ZBE tools, respectively. The VectorZIEL™ rotary steerable system (RSS) is an automatic steering tool for three-dimensional drilling. Offering higher ROP, improved cuttings removal, and precise trajectory control, the system helps you produce higher quality boreholes at reduced operational costs.

We have developed and refined a premium RSS over the course of the past two decades, culminating in the release of the VectorZIEL system. The VectorZIEL system offers reliable and precise directional control in even the most demanding drilling applications. The system is available for purchase or rent and is supported by NOV’s global maintenance infrastructure, enabling directional drillers to offer high-tier directional drilling services around the world.

Features/Benefits

- Integrated MWD system for real-time feedback while drilling

- Near-bit inclination, azimuth, and gamma measurements

- Closed-loop trajectory control, which requires minimal intervention from surface

- Automated downlinking using surface downlink skid

- Can be combined with our MWD and LWD tool portfolio for an integrated directional drilling and logging BHA

RSS tool successfully drills 2,200-ft tangent through challenging formation

NOV’s VectorZIEL™ 600 rotary steerable system (RSS) delivers higher ROP, smoother boreholes, and precise directional control to reduce drilling and well costs in directional and horizontal wells. Our technology has inclination, azimuth, and gamma ray within 5 ft of the bit along with an integrated pulser and is available to independent directional drillers and operators globally

The client needed to drill an 8½-in. hole through challenging hard anhydrite, conglomerates, and interbedded soft silt stone to be at 20° tangent with tight directional control.

Successfully drilled the section using the VectorZIEL RSS with dogleg severity of 6 to 8°/100 ft at an average ROP of 30 ft/hr

石油圈

石油圈