Like a racetrack, a well schematic may seem straightforward to the untrained eye. There is a set path, a series of objectives at which you can either succeed or fail. But once you pass the starting line, you face a new set of challenges— swelling clays, unconsolidated formations, and unanticipated changes in geology. How you respond to these obstacles determines whether you reach total depth (TD) on target and on schedule or fall behind.

The Revolution rotary-steerable system (RSS) puts you in the driver’s seat. With a point-the-bit design that produces a clean hole, the ability to add a motorized BHA, continuous near-bit measurement, and bidirectional downhole communication, you can make informed, real-time decisions.

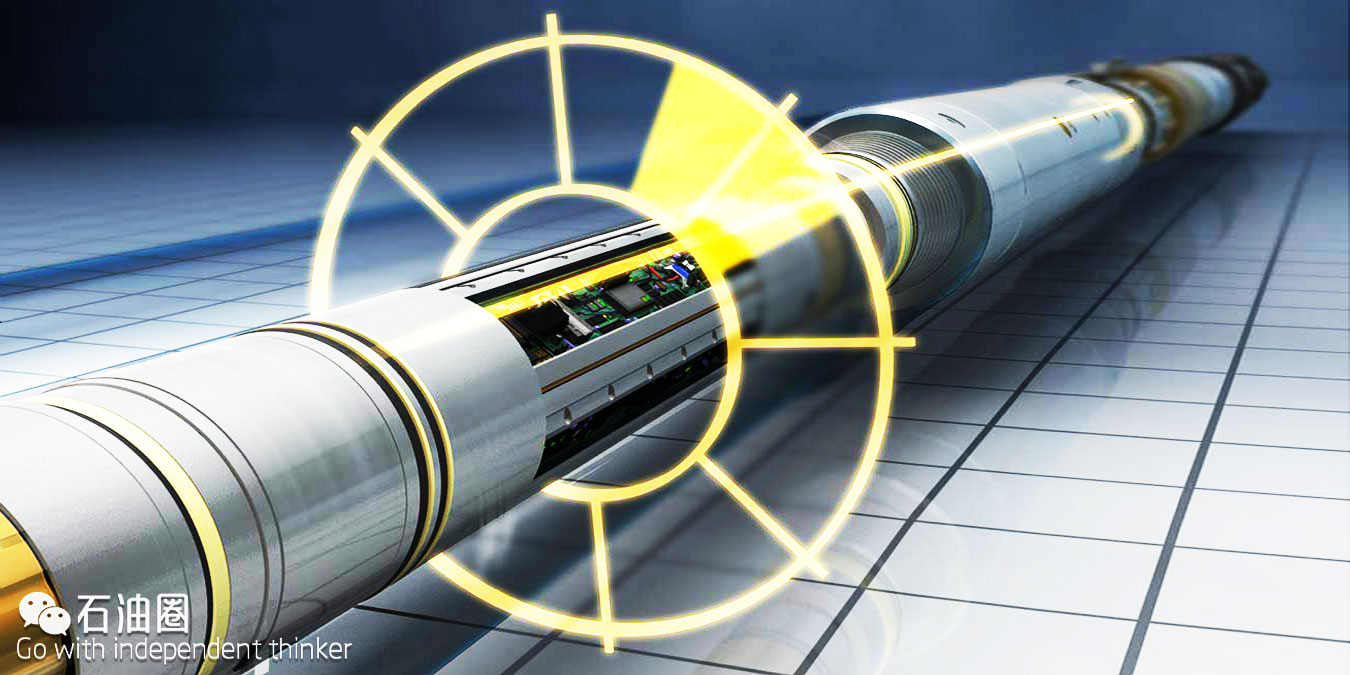

Nonrotating housing

Anti-rotation levers hold the bias unit in place as the drill string rotates to improve steering control and hole cleaning.

Pivot stabilizer

A stabilizer at the fulcrum point controls deflection and minimizes vibration.

By keeping the bit aligned with the borehole, the Revolution system creates smooth wellbores and extends bit life.

Near-bit sensors

Advanced sensors measure inclination, azimuthal gamma ray, whirl, stick-slip, vibration, and other drilling parameters for early detection of formation and borehole dynamic changes.

Self-centralizing, extended-gauge bit

Weatherford works closely with suppliers to select the optimal bit for your application

Revolution Core

Drill complex wellbores in a single run with real-time control

Steer to the front of the pack with the speed and control of the Revolution Core. The point-the-bit design is engineered to maximize rate of penetration (ROP) and to drill a smooth, completion-ready wellbore.

The inherent capabilities of the Revolution system are enhanced with guidance from our Drilling Services team, who help you determine the optimal parameters prior to drilling. These parameters are programmed into the system to enable semi-automated operation. Once the Revolution Core is downhole, onboard sensors deliver real-time inclination and azimuth measurements to the surface.

If the measurements indicate that the wellbore is deviating from plan, the Core quickly adjusts to get back on track without extreme detours or excessive doglegs. You can also make on-the-fly changes to the trajectory from the surface using the downlinking capabilities of the system.

Drilling Motor

The point-the-bit design of the Revolution RSS focuses all of the cutting force at the face of the polycrystalline diamond compact (PDC) bit to achieve a high ROP and produce a smooth wellbore. When you can’t achieve the desired bit speed because of rig-power limitations, you can add the HyperLineTM performance drilling motor or any other commercial motor above the RSS for even greater ROP, lower torque, and reduced stick-slip.

DownLink Commander or EMPulse

Every minute saved during the drilling process is valuable. One way to safely reduce drilling time is to avoid the need to stop the drill string while making trajectory adjustments. The surface-based DownLink Commander® bidirectional communication system uses mud pulses to send and receive signals without interrupting the drilling process. And because the DownLink Commander system works so quickly—sending control signals to the RSS in a matter of seconds and verifying commands within a minute—steering adjustments take effect almost immediately.

When drilling in a lost-circulation zone or with air, foam, or any compressible drilling fluid, you can still achieve real- time communication with the RSS through our EMPulseTM electromagnetic MWD system. Because EM telemetry does not rely on rig hydraulics to transmit data, it has a minimal impact on rig time and resources.

Revolution Heat

As operators seek to produce wells in ever more challenging environments, reliable HTHP drilling equipment is becoming increasingly critical. Weatherford was one of the first service providers to offer a rotary-steerable system for HTHP environments. Our Revolution Heat uses high-viscosity oils and high-temperature-rated Kalsi Seals® to maintain hydraulic integrity while drilling through HTHP zones. The Heat offers the same vertical control, real-time measurement, closed-loop operation, and extended-reach capability as the Core and the V, so you can smoothly and efficiently drill vertical, curve, and lateral sections in zones with temperatures exceeding 300°F (149°C).

Revolution V

When drilling vertically through dipping beds, especially in tectonically stressed environments, the bit tends to move along the path of least resistance. Unfortunately, that’s often not the most efficient path to the target zone. The Revolution V maintains vertical trajectory even in challenging formations, enabling you to drill your well directly to target depth at a high ROP.

Once the Revolution V is downhole, near-bit inclination and azimuth sensors quickly identify any deviation from vertical and automatically adjust for a smooth, efficient return to vertical.

By maintaining a zero-degree inclination, the Revolution V enables you to drill with a higher weight on bit, which increases ROP. The continuous rotation of the Revolution V creates a smooth, stable wellbore and reduces the risk of stuck pipe.

The Revolution V minimizes collision risk when drilling from a pad with multiple, parallel wells, and it is capable of performing small nudges to further separate wells if needed.

Revolution 16

Hitting the right angle is critical at every point in the drilling process. Offering precise drilling of doglegs up to 16° per 100 ft (30 m), the Revolution 16 enables deeper kickoffs that get you to the target zone sooner and maximize reservoir exposure. The Revolution 16 builds from vertical to horizontal in a single run— even in high-dogleg wells—which significantly reduces drilling time and costs.

The Revolution 16 can also be used for reentries and corrections to wells initially drilled with less capable tools. When formation tendencies force the wellbore off plan, the Revolution 16 gives you the extra angle you need to return to the planned path as quickly as possible.

Revolution Slide Reduction Tool

For more than half a century, directional drilling was performed exclusively using conventional mud motors equipped with bent subs. However, this approach requires sliding—rotating the bit downhole while halting rotation of the drill string—which reduces efficiency and ROP. To drill complex, torturous well paths, you need something more precise.

The Revolution Slide Reduction Tool (SRT) fills a unique space between conventional mud motors and rotary-steerable systems. The SRT uses an innovative technique to control bit speed through modulated mud flow. With targeted bit speed and specialized MWD components, the SRT provides efficient directional drilling at a lower cost than rotary-steerable systems.

石油圈

石油圈