Halliburton has released the Xaminer Magnetic Resonance (XMR) Service, the industry’s only high pressure rated (35,000 psi) downhole sensor that provides comprehensive nuclear magnetic resonance measurements to improve reservoir insight. The service delivers more detailed formation data, including 2D and 3D fluid characterization, carbonate pore-size classification, unconventional analysis and permeability.

The service can acquire approximately eight times more data with less than half the power of traditional sensors. It also can be deployed in nearly every open-hole logging environment. XMR helps reduce an operator’s capital expenditures by eliminating the need for multiple sensors.

XMR acquires reservoir information in a single pass to increase reliability and improve data quality. One of the significant advantages of the sensor is its ability to log up and down a well. Operators can retrieve multiple logging passes in one trip, which is critical in poor hole conditions. The data fits seamlessly into advanced integrated analysis platforms, such as ShaleXpert, TurbiditeXpert, CarbondateXpert and TightGasXpert services.

We designed the XMR service to help operators acquire more accurate well data to better evaluate production potential and increase the return on their investment,” Trey Clark, Vice President of Wireline and Perforating, said. “It can be deployed in mature fields, deepwater and unconventional reservoirs to provide superior formation resolution and help reduce field risks.”

Operators evaluating carbonate reservoirs for bypassed oil often observe unrecoverable reserves. An operator in West Texas used the XMR service to evaluate and confirm the presence of unrecoverable oil and avoided lost rig time trying to produce it. The data also validated reservoir zones that only produce saline water preventing costly production testing of these nonproductive zones.

The Halliburton Xaminer® MR (XMR™) service is a true new-generation magnetic resonance technology, engineered to provide excellent bed resolution and evaluate your reservoir’s full range of pore sizes from micro to macro. The XMR sensor provides full MR solutions for basic-to-advanced formation evaluation requirements.

Vertical resolution in thin beds, carbonates, and organic shales is greatly improved over previous magnetic resonance (MR) sensors with a short antenna aperture. Industry-leading pore-size characterization for micropores is achieved from a very fast interecho spacing.

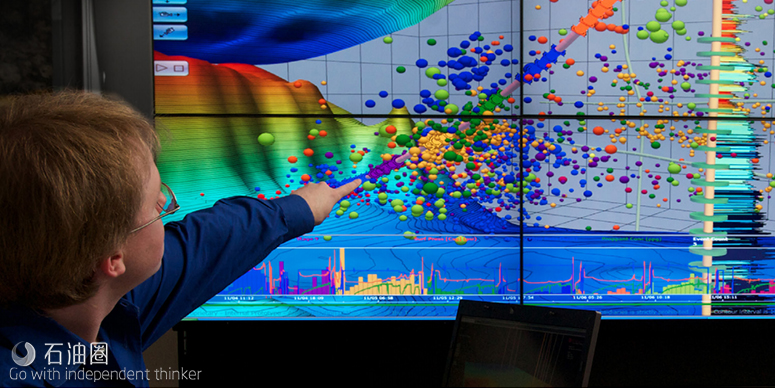

Simultaneous Multi-Acquisition Logging

Best-in-class magnetic resonance answer products are derived from 2D and 3D solutions, which integrate seamlessly into multisensor answer products, including ShaleXpert™, TurbiditeXpert™, CarbonateXpert™, and TightGasXpert™ services.

Direct reservoir-quality assessment is provided from fractionalizing the total MR fluid-filled porosity into components of microporosity, capillarybound fluids, and moveable fluid volume. A continuous permeability estimate is available from multiple methods (Coates, logarithmic mean,and Swanson).

Single Log Pass

The XMR service is fully combinable with the Halliburton LOGIQ®openhole logging suite of sensors to reduce rig time for openhole wireline logging and maximize drilling rig efficiency. The XMR service is deployed as a decentralized sensor with a bowspring to address a wide range of hole sizes from 5.875 in. (149 mm) to 17.5 in. (444 mm)

Finding Success on the Over-Mature Fringes of Organic Shale Plays

An operator in an unconventional play wanted an improved understanding of the subsurface reservoir to characterize thermal maturity near a boundary of its field. Changing source rock maturity, especially as it relates to pore pressure, is a strong driver in field planning. Halliburton was selected to analyze the reservoir and provide a better understanding of the field’s geologic trend, as well as offer timely solutions and recommendations. The CoreVault® RFP (rock-fluid-pressure) system, integrated with additional petrophysical measurements, including the new Xaminer® Magnetic Resonance (XMR™) service, acquired samples swiftly and economically. The petrophysical analysis and core samples retrieved by Halliburton provided guidance for informed decision making on the future of this unconventional asset.

CHALLENGE

Capital-intensive unconventional E&P projects necessitate that a clear understanding of the reservoir is acquired before development occurs to minimize risk and maximize potential. A Marcellus Shale operator in an area of high-thermal maturity needed to make a decision about whether to develop its asset or not. Faced with an expensive plan to frac several development wells to gather the necessary data, the operator sought a more efficient, economical solution and reached out to Halliburton to provide a thorough analysis of the field’s production potential.

SOLUTION

Halliburton recommended using its innovative CoreVault® RFP system, which allows operators in low-permeability and unconventional reservoirs an opportunity to collect selective wireline core and fluid samples. Pressure-sealed, wireline-conveyed rotary sidewall cores eliminate fluid and gas loss during recovery for enhanced fluid property analysis and improved reserve and production performance estimates. This unique solution provides an analysis of the complete reservoir. It’s the industry’s only system to combine downhole fluid sampling, coring, and pressure-temperature measurements for safer, more-reliable production forecasting.

Additionally, the Halliburton XMR service, which offers near-density log vertical resolution, was deployed to evaluate the reservoir’s full range of pore sizes. Direct reservoir quality assessment is provided from fractionalizing the total MR fluid-filled porosity into components of microporosity, capillary-bound fluids, and moveable fluid volume. Other petrophysical tools, as well as subsurface and regional data analysis, were employed to round out the solution.

RESULT

Five CoreVault® runs were conducted within the wellbore, recovering 49 rotary sidewall pressure cores. Enough data on this well was collected to predict the whole geologic trend in the area. By combining the CoreVault RFP and XMR™ data results with regional and specific subsurface information, Halliburton was able to transfer to the client a conclusive analysis of the reservoir characteristics, a better understanding of its economic value, and the risk associated with its reservoir. Wellsite surface analysis of the CoreVault RFP samples and XMR data revealed very little pressure, indicating that this asset would be unfavorable for production. The operator is currently reevaluating its options for the future of this reservoir

石油圈

石油圈