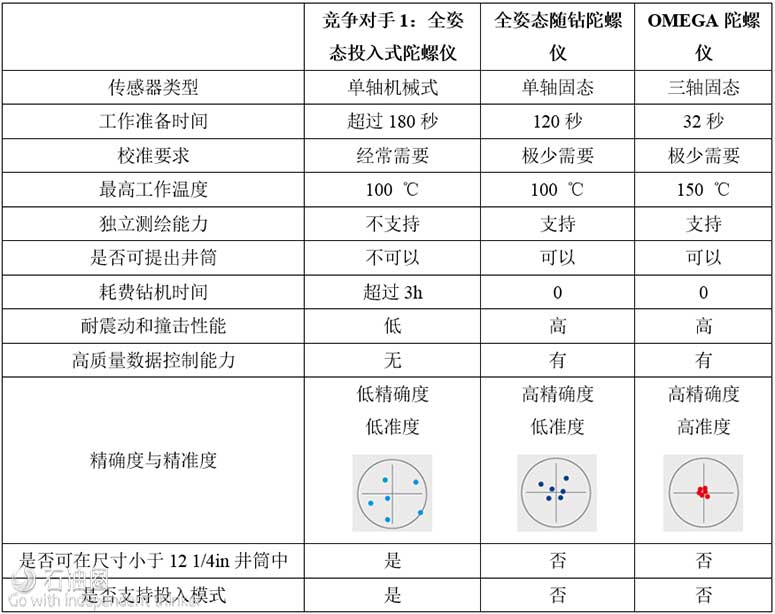

The dawn of a new era in surveying has arrived with the introduction of the OmegaX all-attitude solid-state drop gyro surveying system. Powered by Gyrodata’s ground-breaking SPEAR technology, it’s fast: only 32 seconds to measure the earth’s rotation and gravity fields. And since they are collected during pipe connections, surveys are acquired seamlessly with rig operations taking no additional time. Equipped with an all new solid-state sensor that was internally developed over a ten-year period, the tool’s accuracy is unmatched and does not require regular calibrations and has no mass unbalance error. Quality control is more robust and can now also be verified independently by third parties. The OmegaX solid-state sensors are rugged, ensuring accuracy and reliability in high shock, high vibration and high-temperature environments.

OmegaX reduces the Ellipse of Uncertainty eliminating the need for the added complexity and cost of Wireline Gyros, In-Field Referencing and Multi-Station Analysis corrections.

FEATURES

1.Data collection at 32second sequences for reduced rig time and is four times faster than other gyro providers.

2.The most precise gyro available with repeatable, highly accurate measurements from stable earth rate and gravity field, both constants and neither are affected by magnetic interference.

3.Survey sampling seamlessly occurs with rig operations requiring no additional rig time as the measurements are collected during pipe connections. OmegaX also serves as an independent survey for confirmation of borehole location, which eliminates the need for costly wireline services.

4.The new solid state C.V.G. sensor developed by Gyrodata is highly accurate, does not require regular calibrations, eliminating mass imbalance error present in spinning mass mechanical gyros. OmegaX results in a greatly reduced Ellipse of Uncertainty eliminating the need for the added complexity and cost of In-Field Referencing, Multi-Station Analysis corrections. Saving the cost of a rig day and the cost of the IFR + MSA .

5.Rugged solid-state sensors ensure reliability in high shock and vibration environments, jarring while pulling out of hole or back reaming. OmegaX is capable of withstanding the harsh environments, streamlining daily operations that were once complex operational requirements.

CASE STUDY 1

INDUSTRY CHALLENGE + OBJECTIVE

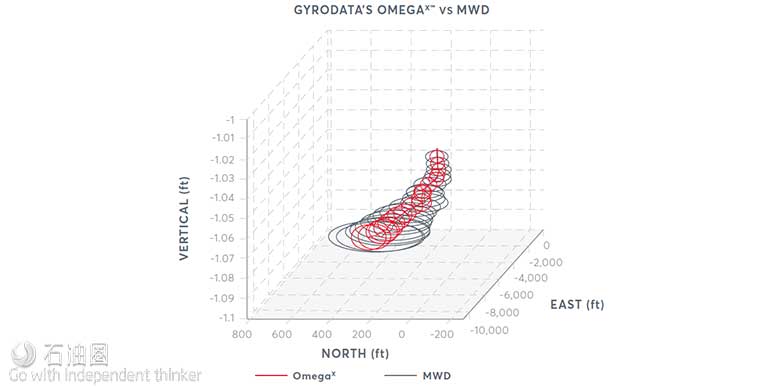

A major operator was drilling a 10,000 ft lateral in the Bakken. This was a west well which utilized MWD multi-station corrections in an exclusion zone which can cause an increased error in the corrected azimuth calculation. This likelihood of increased error created challenges in maintaining the planned wellbore lateral spacing. To minimize the risk of error a more accurate survey solution was required.

TECHNOLOGY + SERVICE SOLUTION

Gyrodata recommended that the OmegaX drop system be deployed, as it surveys at all inclinations with significantly improved accuracy. OmegaX utilizes three orthogonal solid-state CV gyroscopes to eliminate known east/west survey errors. The system was selected to identify the definitive bottomhole location and determine the accuracy of the MWD corrected surveys.

RESULT + VALUE DELIVERED

1.The operator intends to use OmegaX on the remaining wells on this pad. OmegaX showed a 63% reduction in the ellipse of uncertainty compared to the MWD multi-station corrected surveys.

2.The bottomhole location was corrected by 33 feet.

3.By utilizing the OmegaX system in drop mode, an extensive wireline operation was avoided. This saved an estimated 10 – 12 hours of rig time, and the cost of the additional equipment and personnel that would have otherwise been required, a savings of $60,000 per well.

CASE STUDY 2

INDUSTRY CHALLENGE + OBJECTIVE

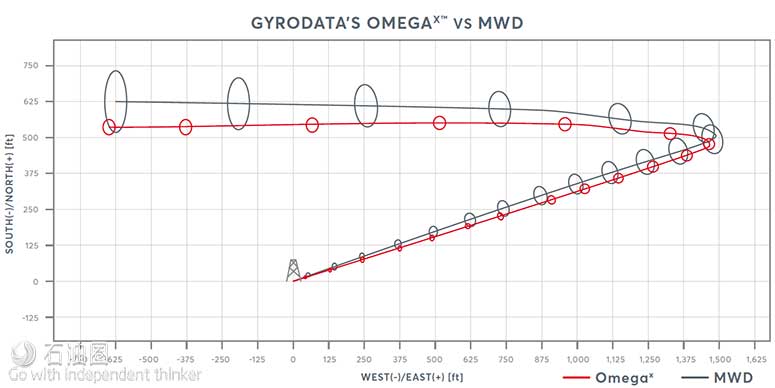

A major operator was drilling a horizontal well in a westerly direction utilizing MWD surveys. This created an important challenge since the success of the project relies on correct lateral spacing. To minimize the risk of error a more accurate survey solution was required.

The DJ Basin has a high density of wells from multi-well pads with fast drilling operations that prohibits real-time multi-station corrections and/or costly wireline operations.

TECHNOLOGY + SERVICE SOLUTION

Gyrodata recommended that the OmegaX drop system be deployed, as it surveys at all inclinations with significantly improved accuracy. OmegaX utilizes three orthogonal solid-state gyroscopes which eliminate known east/west survey errors. The system was selected to identify the definitive bottomhole location by surveying the entire well while tripping out of the hole.

RESULT + VALUE DELIVERED

1.OmegaX accurately corrected the bottomhole location by 91 feet.

2.OmegaX reduced the ellipse of uncertainty (EOU) by 65% in the horizontal well.

3.By utilizing the OmegaX system in drop mode, a time consuming and costly wireline operation was avoided. This saved an estimated 10 – 12 hours of rig time, as well as over $60,000 in costs of the additional equipment and personnel that would have otherwise been required.

4.The operator intends to use OmegaX on the remaining wells on this pad, saving them over $360,000.

石油圈

石油圈