Operators are faced with water-related challenges early in the field development phase, with engineers investigating formation characteristics to ensure proper reservoir and waterflood management. Water injection is the most commonly applied method for secondary recovery, and a tool for improved oil recovery (EOR). But water injection often causes concerns among operators, because good-quality water is necessary to optimize oil recovery. Injecting poor-quality water, such as untreated seawater, can have detrimental effects on the formation, including reservoir plugging, scale formation, corrosion-related issues, and reservoir souring. Installing topside processing equipment enables operators to meet water specifications and avoid these negative effects, but the design for treatment facilities is restricted by weight and space limitations.

The effectiveness of secondary recovery is complicated by: 1) compatibility between injected water and formation water; 2) limited number of wells available, hindering sweep efficiency; and 3) where injected water can reach in the reservoir. In addition, an increasing number of marginal new discoveries have forced the industry to re-think existing techniques to improve secondary recovery and make marginal field development more profitable.

SUBSEA WATER TREATMENT

To solve the water delivery issues, National Oilwell Varco (NOV) developed Seabox technology to move water treatment to the seabed, where it is unconstrained from typical topside restrictions. The subsea system makes water treatment significantly more effective and reduces costs, because there is no dependence on supporting infrastructure. The system’s inherent flexibility enables a new approach to implementing water treatment where, and when, required.

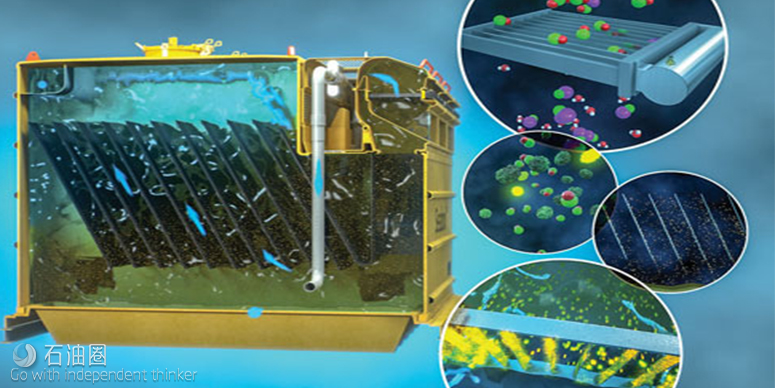

The module consists of three major components: 1) a tray; 2) a still room; and 3) a treatment unit. 2. Each constituent serves a unique purpose in the system’s setup. The module, which has a footprint of 13 × 13 × 8 m, is constructed of fiber-reinforced polymer (FRP) to resist corrosion. Its raw seawater treatment capacity is 40,000 bpd, but this can be increased to 60,000 bpd in certain applications. The treatment unit contains components with a shorter design life and will require an intervention interval every fourth year. Components requiring maintenance include the system’s power and control modules, as well as electrodes, which are essential to the treatment processes. The tray is the module’s base structure. The still room is a sedimentation tank for efficient chlorine soak and solids settling.

At the inlet of the treatment unit, the raw seawater flows through electro-chlorination cells. Sodium hypochlorite is generated, as the cell’s anodes and cathodes react with seawater. This is a common method for disinfecting water. The water treatment module will allow the sodium hypochlorite time to react, due to the residence time within the still room, ensuring optimal disinfection and antimicrobial effect on the raw seawater. The residence time inside the still room ranges from 1 hr to 2 hr, depending on the water path through the still room. The secondary purpose of the still room, and its internal honeycomb structure, is to settle out solids.

The seawater returns to the treatment unit, where it is exposed to the second treatment process at the outlet, when the disinfected water is exposed to a hydroxyl radical generator cell. The system uses boron-doped diamond electrodes to electrochemically generate hydroxyl radicals, which are extremely reactive and used to further decompose organic matter—or to kill bacteria and decompose dead organic matter. Through these treatment processes, the subsea module provides high-quality water near the injection point for increased sweep efficiency, or as a pre-treatment for continued tailoring of water qualities for matrix flooding, low-salinity, or low-sulfate water applications.

ENHANCED OIL RECOVERY

Waterflooding as a secondary recovery method is used in fields all over the world and is often a prerequisite to optimize hydrocarbon recovery. Traditionally, water treatment is acreage-intensive and requires a significant up-front investment, followed by additional ongoing operational costs. The subsea water treatment solution is decoupled from topside infrastructure and provides greater flexibility toward phasing in water treatment according to reservoir requirements, rather than basing an entire EOR program on a few exploration wells.

The module can be deployed in water depths ranging between 50 m and 3,000 m and can be integrated into virtually any application where water could have a positive effect on oil recovery. These scenarios include greenfield and brownfield applications, where water quality specifications and infrastructure integration vary from module integration with existing topside processing facilities, to stand-alone solutions for improved sweep efficiency.

In fields with an urgent need for an improved flooding regime, the module can be combined with existing topside processing equipment to ensure that the water injected is of higher quality than what is available with the existing method. Control of intake water on existing topside processing equipment, can be processed through the module’s disinfection and solid removal systems. This optimizes output of injection water from the existing processing equipment without major topside modifications. The module will perform as an add-on pre-treatment step to an operator’s existing infrastructure, or to increase total water treatment capacity when installed at the foot of a topside facility.

The module’s pre-treatment processing of raw seawater disinfects the fluid after suspended solids, greater than 10µm, have typically settled out. The treated water is then fed to a topside filtration system, significantly reducing the risk of biofouling. This technique enhances the performance of topside filtration units, reduces downtime, and increases the duration between maintenance intervals. The module’s integration flexibility makes it well-suited for brownfield applications, where operators need a solution for water treatment to be implemented quickly with only minor topside modifications.

IMPROVING ECONOMICS

New technologies must be designed to make marginal developments more economically viable, particularly as the number of borderline discoveries continues to increase. One approach to improving marginal wells is using tie-backs, which extend the life of existing production infrastructure. Tie-backs are becoming more important to developing discoveries, and the subsea treatment module is a cost-effective solution for tie-back applications in need of water injection.

In this application, the module’s only topside connection requirement is for communication and power. This eliminates the need for long, high-pressure pipelines to transfer water to the well, in addition to the requirement for chemical injection. Being decoupled from topside infrastructure also makes longer step-outs and secondary recovery more feasible. It reduces particle content and provides completely disinfected water to the reservoir.

The Seabox module, as a stand-alone unit, provides high-quality water for injection. In many waterflooding regimes, the control of sediment levels down to 10µm is sufficient to improve reservoir sweep efficiency. However, operators have developed specific, injected, water quality specifications. To be capable of meeting such specifications, the module can be integrated with existing topside processing equipment.

NOV also is developing a full subsea solution for low-salinity and/or low-sulfate water. By moving the complete water treatment process subsea, the water injection strategy can be fully decoupled from typical platform design and constraints.

FIELD TESTING

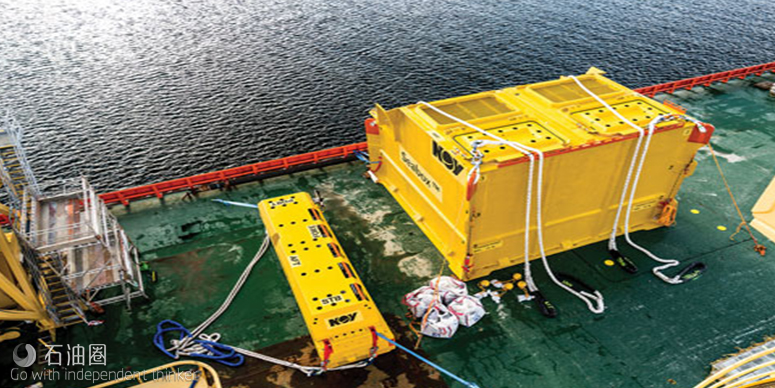

The first full-scale unit was installed off the coast of Stavanger, Norway, in February 2018, at a water depth of 220 m, Fig. 4. Water was drawn topside through a 540-m pipeline via a submerged pump and discharged to sea. The two primary objectives of this installation were to gain operational experience during a three-month test program and to verify the treatment capabilities of the module. The test program was set according to oil industry practice, and sampling and analysis were provided by a third party. The aim was to confirm the theoretical calculations regarding disinfection and solid removal capabilities. The subsea water treatment module removed, on average, 60% of all particles using sedimentation only.

NOVOS software enables automation of repetitive drilling activities, allowing drillers to focus on consistent process execution and safety. The scalable system can be expanded to full closed-loop automation. An imported well plan describes desired drilling parameter ranges, enabling the system to optimize the performance within the given set of parameters based on the well plan. Users can set parameters to meet requirements, including circulation and WOB.

The result of the general heterotrophic bacteria and sulphate-reducing bacteria was below detectable limits, demonstrating complete bacteria kill through the exposure of electrochemically produced sodium hypochlorite, residence time, and hydroxyl radical generation. Throughout the test period, the water treatment module showed stable performance with high regularity, providing treated water with a consistent solid removal and disinfection capability, despite fluctuation in raw seawater quality.

North Sea field installation. In August 2018, the company installed full-scale production units in a test project on a real-field application. This module is now a part of an operator assessment program in the North Sea, to investigate the module’s ability to prolong field life and make marginal discoveries more feasible. The module was made operational at a 75-m water depth in September. The test program is scheduled to complete during second-quarter 2019. The Seabox module is now accepted as a Technology Readiness Level (TRL) 6, according to the API 17N standard. With the completion of an ongoing joint industry project for development of a subsea low-salinity processing plant, NOV will bring its SWIT technology for subsea low salinity and/or sulfate removal to TRL 6 during 2019.

VALUE PROPOSITION

The Seabox subsea water treatment technology provides operators with the ability to optimize reservoir management. The module is not restricted by the existing capacity of topside infrastructure and can increase availability on water injection. By exploiting the unlimited acreage of the seafloor, the footprint of topside infrastructure can be reduced significantly, and the operator will gain greater flexibility toward the integration of a water treatment solution adapted to specific reservoir requirements. The module can drive down operational costs connected to water treatment by reducing topside maintenance and offshore personnel requirements, and can enable a move toward unmanned platforms.

The subsea water treatment process has no added chemicals. The sodium hypochlorite and hydroxyl radicals generated are produced electrochemically in situ, where the chemical processes are dissolved in seawater without creating an environmental footprint. The module typically requires less than 10 kW, approximately 50 times less than similar surface water treatment plants with the same capacity. The module’s inherent flexibility requires a smaller upfront investment on field developments. It avoids unnecessary expenditures of rebuilding existing infrastructure to meet water injection needs.

SUMMARY

Flexibility. Water injection philosophy can be decoupled from topside processes to provide advantageous flexibility in drainage strategy.

Improved recovery. There is an ability to tailor an injection, based on reservoir behavior and the possibility to inject any quality water in otherwise inaccessible areas of the reservoir.

Reduced capex. There are lower overall investments and increased net present value by deferment of cost.

Lower opex. There is lower power consumption, compared to topside units. Long periods exist between required intervention intervals. Offshore personnel requirements are reduced.

High reliability. There are no rotating or moving parts, combined with built-in system redundancy.

石油圈

石油圈