Aptara™ Modular Compact Pump

Subsea boosting

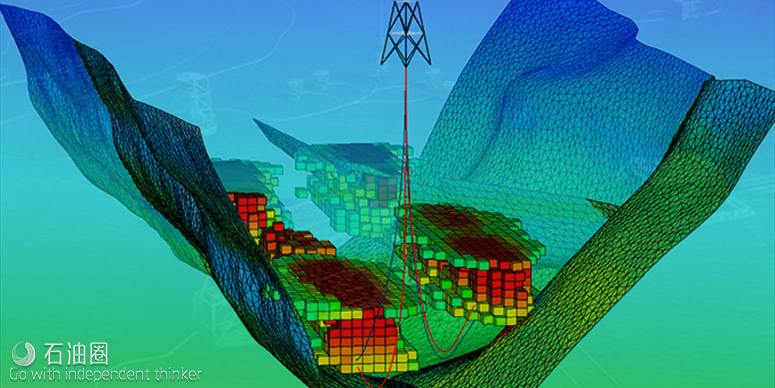

Our Aptara™ Modular Compact Pump (MCP) is the world’s first subsea multi-phase pump without a barrier fluid system requiring less maintenance and saving cost. It is a completely integrated, all-electric boosting system that can accelerate and improve your oil recovery in both new and mature wells by adding energy to multi-phase wellstreams and by lowering wellhead pressure.

A game-changer in subsea multi-phase boosting

Our Aptara™ MCP is part of the TOTEX-lite family of subsea solutions and can unlock and enable access to your assets, even under the most challenging conditions, such as long tie-backs, low-pressure reservoirs or wells with difficult flow assurance. It provides a cost-effective and efficient solution, and unlike conventional subsea multi-phase pumps, which use a high-speed motor to drive a long shaft connected to a series of impellers, the MCP has a unique architecture with integrated motor impellers that rotate around a static shaft. This eliminates potential rotodynamic issues, whereas in a conventional pump, the motor is connected to the same shaft that drives the impellers, which limits the number of stages that can be stacked.

Our life-of-field approach to design is evident in the Aptara™ MCP’s unique features that reduce total cost of ownership.

Modular Compact Pump

- 50% less footprint… topside and subsea

- No barrier fluid system design with a less complex, lighter umbilical

- Modular and scalable

- Configurable over the life of field, with standard, pre-qualified 1MW building blocks

Aptara™ Composite Flexibles

A step-change in capability and cost to the subsea industry

BHGE’s composite riser flexible pipe is a step-change product. It provides a cost-effective solution for ultra-deepwater applications in water depths up to around 10,000 ft (3,000 m).

Designed for ultra-deep waters and high pressure applications

This new product is a hybrid of traditional flexible pipe designs, introducing 21st century materials technology for one specific layer – bringing 30% weight savings without affecting bending radius or compressive load capability.

For risers, this is achieved by reducing hang-off weights and platform burdens, simplifying riser configurations, and minimizing ancillaries and subsea infrastructure while keeping the exposure to new technology to a minimum.

The product eliminates riser system complexity, reduces cost and installation time while delivering predictable and stable hydrodynamic performance over the full product life cycle.

For flowlines and jumpers, we retain the flexibility this product brings with regards to final layouts, accommodating re-spuds and early deployment/wet storing of pipe to accommodate installation windows of opportunity, which may occur off the project critical path.

Particularly for high-sour or high-CO2 developments, this hybrid composite pipe significantly reduces permeated gas flow rate through the pipe annulus, reducing operational risk and adding cost benefits over the field lifecycle.

These flexible pipes are re-usable and can be redeployed to different duties and locations.

Aptara™ SFX Wellhead Solution

Designed for improved fatigue resistance to maximize life-of-field options for operators

The SFX wellhead solution, part of the Aptara™ suite of TOTEX lite products, takes the field-proven architecture of our MS-700 and MS-800 subsea wellheads to the next level — delivering up to 16 times fatigue resistance improvement over existing systems. It also offers reduced cycle times, and extended drilling days in harsh environments.

Improvements:

Stress-reducing geometries

Longer socket spacing

Extended length forgings

Tougher materials: A707 and F22

Tighter pipe tolerances

State-of-the-art welding

Improved and standardized inspection protocols

for greater reliability and safety

Reduced number of welds

Eliminated short pipe sections

Advantages of standardized design:

Enables both MS-700 and MS-800 configurations

Maintains all familiar system interfaces, tools, and operating procedures

5″ of extra sealing surface for compatibility with all completion system

Lead times:

Can be delivered within 6 months, which is 8 months faster than a traditional wellhead

Aptara™ Subsea Connection Systems

Next generation, multi-function, quick-connection systems

Our FLX360 is an innovative Multi-Quick Connect (MQC) system that enables fast and reliable connections between all elements of the subsea distribution system. The HCCS-L, also part of the APTARA suite, is a lightweight horizontal clamp connector suitable for rigid and flexible jumpers and spools, as well as, umbilical termination with multi-bore hub technology.

Designed to reduce CAPEX and maximize reliability

The FLX360 Multi-Quick Connection (MQC) System enables fast and reliable connections between all elements of the subsea distribution system. It uses a patented locking mechanism that leaves only one moving part of the design on the seabed. The complexity of the connection system is housed within the retrievable and serviceable ROV tooling, eliminating screw threads from the system and enabling reliable make up/ break out times of approximately 90 seconds. Its unique life-of-field design also allows maintenance in situ with no need for disconnection of the connector thereby reducing total cost of ownership.

The HCCS-L Lightweight Horizontal Clamp Connection System is a proven horizontal connector suitable for rigid, and flexible jumpers and spools, as well as umbilical termination with use of multi-bore hub technology. The HCCS-L range has been designed to be lighter, smaller and optimized to minimize make-up time, allowing for rapid installation. They come with a pre-mounted stroking tool and require fewer subsea operations, reducing the connection time by more than 30%. Our unique push-type stroking functionality allows full access for cleaning and cap replacement with the pre-mounted stroking tool.

石油圈

石油圈