BHGE推出的Subsea Connect与Aptara TOTEX-Lite水下系统,可以最大化海上油气开发的价值!

来自 | BHGE

编译 | TOM 惊蛰

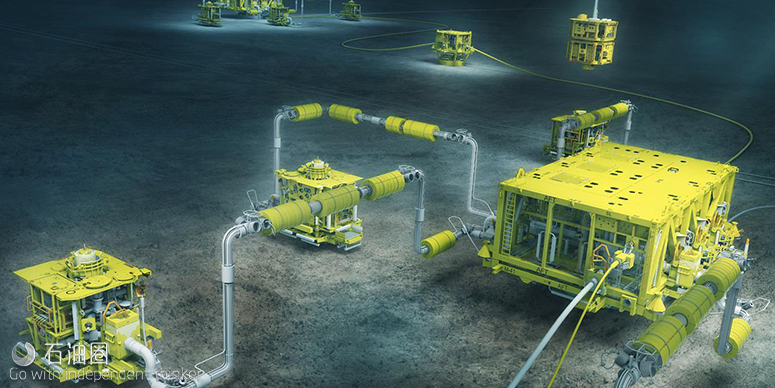

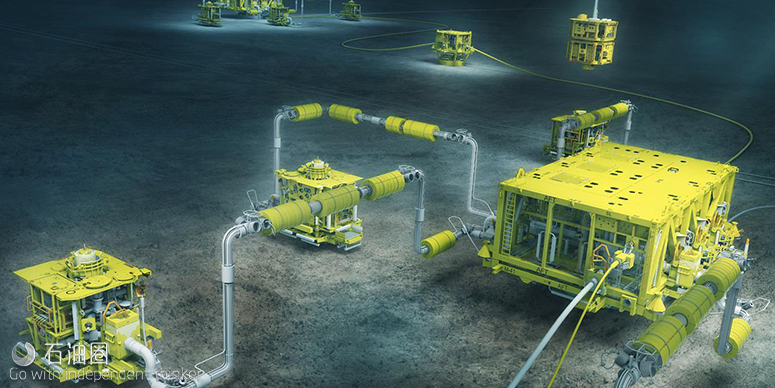

贝克休斯(BHGE)宣布推出水下开发新方法Subsea Connect。该方法主要包括Aptara TOTEX-lite水下系统,这是一套全新的轻型模块化技术,专为油田全生命周期而设计。通过将规划与风险管理、新型模块化深水技术、创新型合作伙伴关系以及数字工具结合在一起,Subsea Connect可以将水下项目的经济开发成本平均降低30%,并有可能在全球释放160亿桶的额外储量。

凭借其全方位的技术产品组合,以及在整个开发过程中建立更紧密连接的能力,BHGE将目标设定为撼动海上开发项目所需成本中的80%。这为降低开发商的资本支出与运营成本,以及提高未经批准的项目商业可行性的项目提供了机会。

BHGE油田设备业务总裁兼首席执行官Neil Saunders表示:“近年来,我们在降低水下项目成本方面取得了不错的进展,与陆上开发项目相比,它们已变得更具竞争力。虽然差距已经缩小,但我们正通过Subsea Connect将其提升到一个新的水平。在油田全生命周期内,实现从概念设计到试运行的长期、可持续变革。”

Subsea Connect是四个关键解决方案的组合:

- 项目连接:BHGE的独立工作流程,始于有针对性的项目成果,为客户提供独立、灵活的项目评估与管理。项目连接方法消除了项目回收,降低了成本与项目超支,并提高了最终投资决策(FID)的速度。BHGE在整个价值链中具有无与伦比的广度与深度,能够在概念评估阶段尽早参与,并加强协作,从而改变项目的经济效益。

- 油藏至海上平台技术方案:BHGE的全流程能力涵盖了从油藏至海上平台的各个方面。远远超出了水下范围,包括油藏管理、油田开发、建井、海上平台优化以及水下工程。BHGE的Aptara TOTEX-lite水下系统包括轻型紧凑型采油树、模块化紧凑型管汇、柔性复合立管、SFX井口解决方案、模块化紧凑型泵以及水下连接系统。这些技术是模块化的、结构化的、紧凑的,旨在对整个油田生命周期中不断变化的条件做出更多响应,将总体拥有成本降低多达50%。

- 灵活的合作伙伴关系与商业模式:BHGE的合作模式非常灵活,旨在利用最高效、最成熟的合作伙伴关系,来满足客户的需求并提高项目经济效益。BHGE的创新型商业解决方案与客户的优先事项保持一致,有助于释放更多价值。

- 数字化支持:BHGE利用下一代数字解决方案将关键技术分为不同层级,以延长正常作业时间并提高生产力。BHGE的engageSubsea资产生命周期管理方案就是具有代表性的例子。该方案旨在优化水下项目的规划、执行与连接,从而加强资产维护的执行与远程管理。engageSubsea通过预测分析将资产维护成本降低了2%,并将停机时间降低了5%。

Saunders说:“我们已经开始交付项目连接方案了。除了引入新的技术解决方案外,我们还在开发我们的水下生产系统(SPS)产品系列方面投入了大量资金,以确保缩短交付时间(高达30% ),并提高反馈速度,我们的SPS产品目录证明了这一点。包括一整套‘按订单生产’,‘按订单配置’以及‘按订单设计’的定制产品。我们还与一家大型油气公司签署了一项协议,在明年为该公司提供Aptara轻型紧凑型采油树。”

在德克萨斯州休斯顿举行的发布会上,BHGE公司将向各大油气公司揭晓Subsea Connect,Aptara TOTEX-lite水下系统以及SPS产品目录。

Aptara轻型紧凑型采油树

重量减轻50%,专为油田全生命周期内的灵活性而设计。“我们革命性的Aptara轻型紧凑型树轻巧紧凑,基于油田全生命周期方法,不仅可以降低初期资本投入,还可以降低油田全生命周期内的运营成本。这种TOTEX-lite方法采用了业内领先的独特设计,可以在海床上进行调整,以满足客户油田在全生命周期内不断变化的需求。”

创新设计、轻型,满足您的生产需求。在油田全生命周期内,Aptara轻型紧凑型采油树系统可根据客户的需求进行调整,并可实现即插即用,无需引入额外的水下设备,比如水下增压泵。与传统的深水水下采油树树相比,它的占地面积显著减少,这意味着设备本身的重量减轻了50%,并且可以将总支出(资本投入与运营支出)降低50%以上。

Aptara采油树使客户能够升级采油树系统,以适应不断变化的储层条件。该采油树拥有业内首创的独特专利设计,包括采油树的创新型流动路径与“采油树帽”,还集成了管道完整性保护(HIPPS)与增压等功能,可降低总体开发成本,并提高油藏采收率。油田全生命周期的采油树帽还可以促进水下油井从生产井转换为注水井,调整水下基础设施以满足油藏管理的需要。

- 专为油田全生命周期内的灵活性而设计;

- 在油田全生命周期内,无需引入额外的水下设备,创新型流动路径可实现管道完整性保护、采油树帽与泵帽的安装;

- 重量减轻50%;

- 10个月的交付时间;

- 智能实时监控。

Aptara模块化紧凑型管汇

“简言之,就是用简易挑战复杂。BHGE正在重新思考水下油田的未来。我们推出了新的Aptara系列TOTEX-lite产品,从而简化了水下油田的复杂性。Aptara模块化紧凑型管汇是该系列轻型、智能化水下设备的一部分,旨在降低客户的油田全生命周期的总体拥有成本。”

紧凑设计,增强了可操作性与可靠性。设计Aptara™模块化紧凑型管汇系统的目的,就是要满足业内对模块化、预定制、可用常备配件管汇的需求,从而缩短周期时间成本,并减小设备占地面积。BHGE新型管汇的紧凑型设计可简化水下油田的复杂性。

Aptara管汇设计采用4槽或6槽双集管配置,以满足客户的管道需求。5英寸或7英寸分支阀块可用于该管汇的分支阀连接,且带有独立的集管管道。管汇分支阀与我们的Aptara轻型紧凑型采油树系统阀(例如5英寸采油树需要5英寸管汇分支阀)相同,将标准化的界限扩展到了新的水平。如此一来,就可以大量购买阀门与锻件等部件,从而降低成本与交付周期。

For English, Please click here (展开/收缩)

Baker Hughes (BHGE) has announced the launch of its new approach to subsea development: Subsea Connect, including its Aptara TOTEX-lite subsea system, a suite of new lightweight, modular technologies designed for the full life of field. By combining planning and risk management, new modular deepwater technology, innovative partnerships and digital tools into a single offering, Subsea Connect can reduce the economic development point of subsea projects by an average of 30% and has the potential to unlock an additional 16 billion bbl of reserves globally.

With its fullstream portfolio and ability to make better connections across the development process, BHGE is positioned to influence approximately 80% of the costs associated with offshore projects. This provides an opportunity to lower operators’ CAPEX and OPEX requirements and transform unsanctioned projects into commercially-viable ones.

“In recent years, our industry has made good progress in lowering the cost of subsea projects to the point where they have become more competitive with onshore developments,” Neil Saunders, President & CEO of BHGE’s Oilfield Equipment business, said. “While the gap has narrowed, we are taking that to the next level with Subsea Connect, making long-lasting, sustainable change and driving value from concept to commissioning and over the full life of field.”

Subsea Connect is a combination of four key solutions:

- Project Connect: BHGE’s independent workflow begins with targeted project outcomes, offering customers independent, flexible project assessment and management. The Project Connect approach eliminates project recycle, reduces cost and project overruns, and increases speed to Final Investment Decision (FID). BHGE’s unmatched breadth and depth of capability across the value chain enables early engagement at the concept evaluation phase and greater collaboration, transforming project economics.

- Reservoir to Topsides Technology Solutions: BHGE’s fullstream capability covers all aspects of a development, from the reservoir to the topside. This goes beyond the subsea scope and includes reservoir management, field development, well construction, topside optimization and subsea engineering. BHGE’s Aptara TOTEX-lite subsea system includes the lightweight compact tree, modular compact manifold, composite flexible risers, SFX wellhead solution, modular compact pump and subsea connection systems. These technologies are modular, structured, compact and designed to be more responsive to changing conditions across the life of field, cutting total cost of ownership by up to 50%.

- Flexible Partnerships and Commercial Models: BHGE’s partnership model is flexible and designed to leverage relationships with the most efficient, established partners to meet customers’ needs and improve project economics. BHGE’s innovative commercial solutions, aligned with customer priorities, help to unlock additional value.

- Digital Enablement: BHGE is layering critical technologies with next-generation digital solutions to drive greater uptime and enhance productivity. BHGE’s engageSubsea asset lifecycle management solution is one example, designed to optimize the planning, execution, and connectivity of subsea projects, resulting in enhanced execution and remote management of asset maintenance. engageSubsea will drive up to a 2% reduction in maintenance costs, and up to a 5% reduction in downtime through predictive analytics.

“We’re already delivering against Subsea Connect,” Mr Saunders said. “In addition to the introduction of new technology solutions, we have invested significantly in structuring our subsea production systems (SPS) portfolio to ensure shorter lead times – by as much as 30% – and quicker responses, evidenced by our comprehensive SPS Catalogue, which includes a full suite of ‘Make to Order,’ ‘Configure to Order’ and ‘Engineer to Order’ variants. We have also signed an agreement with a major operator to provide the Aptara lightweight compact tree for deployment next year.”

Subsea Connect, the Aptara TOTEX-lite subsea system and BHGE’s SPS Catalogue were unveiled to E&P customers at a launch event in Houston, TX.

Aptara™ Lightweight Compact Tree

Up to 50% lighter, designed for life of field flexibility

Our revolutionary Aptara™ Lightweight Compact Tree is lightweight and compact and uses our life-of-field approach to reduce not just initial CAPEX but also OPEX over the entire life of your field. This TOTEX-lite approach uses a unique industry-first cap design that allows it to be adapted on the seabed to address the changing requirements of your field over its life.

innovative design, lightweight, adaptable to your production needs

The Aptara™ Lightweight Compact Tree system adapts as your needs change through the entire life of your field, with a plug and play capability in the cap without the need to introduce additional subsea equipment like subsea boosting. It has a significantly reduced footprint compared with traditional deepwater subsea trees, which means 50% less weight and the potential to reduce TOTEX (CAPEX + OPEX) by more than 50%. The Aptara™ tree allows you to evolve your tree system to suit changing reservoir conditions. Its unique patented industry-first design involves an innovative flow path and ‘caps’ for the tree that integrate functionality such as High Integrity Pipeline Protection (HIPPS) or add boosting capability to reduce your overall development cost or increase reservoir recovery.

The life-of-field cap also facilitates conversion of subsea wells from producer to water injection, adapting your subsea infrastructure to meet your reservoir management needs.

SELECT FEATURES

- Designed for entire life of field flexibility

- Innovative flow path enabling installation of HIPPS, production and pumping caps without need for other subsea kit through life of field

- Up to 50% lighter

- 10-month lead time

- Smart real-time monitoring

Aptara™ Modular Compact Manifold

hallenging complexity with simplicity

BHGE is rethinking the future of subsea fields. We are simplifying the complex by launching the new Aptara™ family of TOTEX-lite products. The Aptara™ modular compact manifold is part of this family of light and smart subsea equipment designed to reduce the total cost of ownership over the life of your field.

Compact design with enhanced operability and reliability

Our Aptara™ ,modular compact manifold system has been developed to address the need for modular, pre-engineered manifolds that use off-the-shelf components, reducing cycle time cost and footprint. The new compact manifold from BHGE has been designed to challenge complexity with simplicity.

The Aptara™ manifold design uses a 4-slot or 6-slot dual header configuration to suit your pipeline requirements and 5-inch or 7-inch branch valve blocks for its branch valve connections, with separate header piping. The manifold branch valves are identical to our Aptara lightweight compact tree system valves (e.g. 5-inch trees require 5-inch manifold branch valves), pushing the boundaries of standardization to the next level. This enables large volume purchase of components like valves and forgings, allowing us to hold the stock you need – reducing cost and lead time.

未经允许,不得转载本站任何文章:

石油圈

石油圈