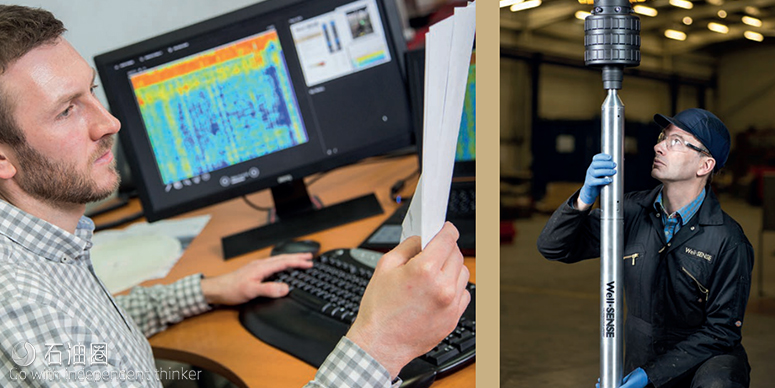

Well-SENSE has announced the launch of its latest FiberLine Intervention (FLI) development, ‘Active FLI’ at ADIPEC.

Active FLI builds on the capability of Well-SENSE’s fiber-optic downhole data acquisition system with the addition of a range of discrete measurement devices. These include single-point temperature and pressure sensors, with the addition of a casing collar locator for depth correlation. The tools are located in the FLI probe to capture measurements as it descends downhole and complement the distributed sensing, which takes place along the length of the fiber-optic lines deployed in the well by FLI.

The combination of single-point and distributed data provides enhanced well intelligence and allows events occurring in the well to be precisely located, verified and quantified via different data sets. This capability extends the use of FLI to a wide variety of applications across the complete lifecycle of the well such as completion verification, production profiling or integrity investigation.

“We are delighted to be launching our latest FLI technology at ADIPEC,” Craig Feherty, Well-SENSE CEO, said. “Earlier this year we secured significant investment from Saudi Aramco Energy Ventures (SAEV) which has allowed us to further develop FLI and is supporting the commercialization process.”

“Active FLI is the only downhole-sensing system on the market to combine distributed and single-point data acquisition in one low-cost disposable tool,” Mr Feherty said. “This creates a much richer picture; it’s almost like comparing a 3D color video to a black and white photograph. Add to this, our simple, user-friendly plug and play deployment system and you end up with a customer-controlled, low-risk, low-cost system which can give you a clear insight into every downhole scenario across the lifecycle of the well.”

FLI is a complete intervention system and does not rely on wireline, slickline, or coiled tubing for deployment. It places bare fiber-optic lines into oil and gas wells to capture high-definition, real-time data. The length of the fiber acts as a sensor and delivers a complete temperature, pressure and acoustic profile of the well from top to bottom, simultaneously, over time.

The fiber, probe and all downhole electronics are single use and disposable, being left in the well to dissolve following project completion. The user-friendly, customer-operated plug and play system, combined with the disposable nature of the technology, means that intervention downtime, wellsite footprint, personnel requirement and associated cost and risk are all negligible.

Game Changing Technology

FiberLine Intervention (FLI) from Well-Sense is a unique and innovative method of collecting diagnostic data from oil and gas wells using disposable fiber optics. FLI will quickly and cost-effectively install a temporary fiber optic line into a well for the purposes of performing distributed data sensing over its entire length in real time. FLI deploys a bare line and is completely disposable, being designed to dissolve in the well environment after use.

Temperature, pressure and acoustic data can be captured, plus active single point measurements and live HD video, providing operators with a detailed understanding of a single well or field of wells. FLI’s tractor conveyancing permits tools to be deployed to depths and deviations previously thought uneconomical. The increase in understanding from this type of accessible, fast, low cost well monitoring will lead to much more efficient recovery of hydrocarbons.

THE FOURTH INTERVENTION FLI is an entirely new discipline for intelligent well intervention. It provides clients with a fourth and alternative option over conventional wireline, slickline or coiled tubing intervention at a significantly reduced cost. Being extremely compact, simple to deploy and disposable, the time to rig up and down and the amount of equipment and personnel required to perform the job is drastically reduced.

FiberLine Intervention enables cost effective: > Distributed fiber optic sensing > Production logging > High-bandwidth downhole sensing

FiberLine Intervention reduces: > Health, safety and environment risks > Personnel and equipment on wellsite

HOW DOES FLI WORK?

The FLI probe, containing the fiber optic line on an internal spool, is dropped down the vertical section of the well, unspooling the line without tension as it free falls downhole. During the survey, the fiber line uses a continuous beam of laser light which encounters interference at points along its length, depending on environmental factors. For example, if it is measuring acoustic profiles, a sound will be generated at source and the changes in soundwave pressure frequency will be measured. Our fiber optic lines can deliver real-time measurements, over their full length, over a period of time and data is captured by a recording device at the surface. FLI is different to other fiber optic measurement devices as it is run into the well as bare line, without being encased within an intervention media. Once it is run and has delivered the necessary data it is disposed of in the well and does not result in an obstruction. This is the only fiber optic sensing method for oil and gas wells that is disposable.

FLI provides huge time, space, transport and cost savings, removing the need for intervention media such as coiled tubing or wireline to deliver the fiber into the well and its associated surface spooling equipment and personnel, complicated rigging up and down and associated non-productive time.

The FLI kit can be delivered to site on the back of a pick up truck, or in a small container offshore, and be ready to run in less than an hour compared to around ten hours to rig up slickline. There is less risk of getting stuck in hole, less risk of lost equipment and no lost in hole charges. There is no NPT associated with rigging down.

石油圈

石油圈