Baker Hughes has released of its DeepShield deepwater safety valve, the industry’s first V1-validated subsurface safety valve tested to help ensure fail-safe operations as defined in the new API Spec 14A. The DeepShield valve is designed to close if well control is lost—even in the presence of debris buildup—establishing a reliable safety barrier to help minimize the likelihood of reservoir fluids escaping up the wellbore and any resulting health, safety and environmental impacts.

The DeepShield valve features a patented, redundant operating system that enables the valve to function at extreme depths and pressures. Unlike conventional valves, the DeepShield valve can be held open at lower pressures, reducing infrastructure costs required to maintain higher wellbore pressures during operations.

“We are committed to protecting people, habitats and the environment, and the DeepShield valve reinforces this commitment in offshore deepwater wells,” said Zac Crouch, Vice President, Completions and Wellbore Intervention at Baker Hughes. “Because our rigorous safety valve testing protocols already exceeded earlier validation standards, we were able to quickly integrate the new specifications into our testing program. Baker Hughes is the first company to meet the new V1 validation, which marks a new standard for safety and reliability in the Gulf of Mexico.”

The American Petroleum Institute announced the Twelfth Edition of API Specification 14A, Subsurface Safety Valve Equipment, in February 2015 with an effective date of 15 January 2016.

The DeepShield subsurface safety valve is the latest example of Baker Hughes’ strategy to improve well efficiency, optimize production and increase ultimate recovery.

http://assets.cmp.bh.mxmcloud.com/system/c1/c9d7600edd11e5873b559b21094f0e/43063-DeepShield-Overview.pdf

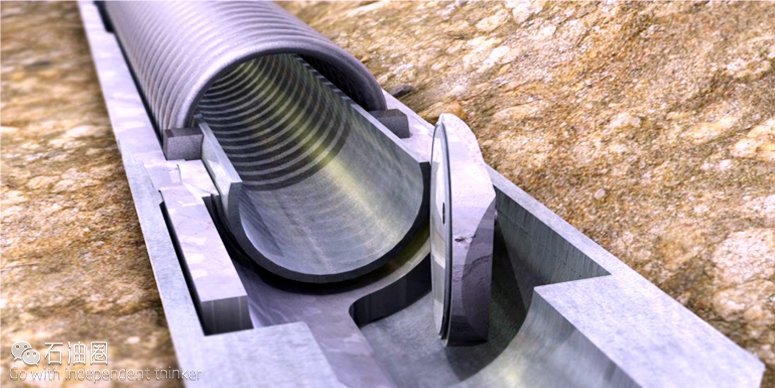

The Baker Hughes DeepShield™ deepwater subsurface safety valve delivers fail-safe performance in completions that require low operating pressures due to control system limitations. The patented DeepShield operating system provides simple and reliable operation in the most critical applications.

The DeepShield safety valve is the industry’s first V1-validated valve as defined in API SPEC 14A Specification for Subsurface Safety Valve Equipment, Twelfth Edition. Per this specification, subsurface safety valves must now undergo more stringent prototype testing than was previously required. With only minor modifications, the Baker Hughes subsurface safety valve prototype test program was able to accommodate the new V1-validation specifications, and continues to exceed the requirements set forth by API.

The DeepShield safety valve uses an integrated nitrogen-charged system that opposes the hydrostatic pressure acting on top of the piston.

Balancing the hydrostatic pressures ensures low operating pressures, even in deepwater applications. The dynamic seal configuration used for the operating piston represents a significant engineering achievement that uses reliable, field-proven sealing technology designed for nitrogen-charged safety valves. The valve features a patented operating system capable of closing in all applications, even if primary nitrogen chamber pressure is lost.

To ensure long-term nitrogen containment, the DeepShield valve includes an enhanced dynamic seal configuration, upgraded dynamic seal materials, increased volume in the secondary chamber, internal alignment enhancements, redundant seals in the fail-safe piston, reduced leak path in primary nitrogen coils, and upgraded materials for low-pressure sealing performance of the check seats in fill ports. An energized scraper ring minimizes ingress of debris in harsh environments, and a stronger power spring is also available for higher closing force in heavy debris applications.

The DeepShield valve has two independent operating systems and an integral control line filter, delivering redundancy and assurance ideal for use in remote subsea wells. When it comes to your critical applications, the innovative design and simple operation of the valve makes it a smart choice for protecting your people, the environment, and your investment.

Applications

■Completions requiring low operating pressures due to control system limitations

■Remote subsea wells

■Deepset wells in dry-tree applications

■Completions requiring a V1-validated safetyvalve

Features and Benefits

■Field-adjustable primary nitrogen chamber

–Enables last-minute adjustments to match changing wellconditions

■Two independent, patented operatingsystems

–Offer redundancy to maintain dependable valve operation

–Ensure fail-safe operation in criticalapplications

■Samemoving parts as a conventional tubing-retrievable subsurface safety valve

–Simplifies operation

–Increases certainty

■Piston wear bearing and scraper ring

–Minimizes ingress of debris

–Maintains functionality in harsh, debris-laden environments

■Low operating pressure at any setting depth

–Reduces operating system cost

■Baker Hughes RBT metal-to-metal thread technology

–Provides gas-tight sealing in harshenvironments

–Enables high tensile rating

■Optional integral control line

–Offers clean and trouble-free operation

石油圈

石油圈