昨天为大家带来了威德福新井建技术的简介,今天就带来两种工具的详细介绍!

来自丨Weatherford

编译丨TOM

针对陆地与海洋作业的不同特点,威德福为Vero技术设置了两种模式,分别为针对陆地作业的常规系统以及针对海洋作业的机械系统。

Vero常规系统

Vero常规系统可以优化管柱的自动接卸扣与评估,用于陆上与浅水钻机的连接作业,主要应用范围包括标准管柱、优级、耐腐蚀合金(铬)管柱以及完井管柱,该工具具有诸多的特点与优势。

Vero常规系统通过计算机控制的精度,自动完成最终接卸扣,以提高效率与完整性:通过一种速度控制算法,利用连续的扭矩测量,会在接近最佳扭矩时提示系统自动减慢上扣速度。这些速度调整消除了传统倒泄阀的需求,而且不会造成上扣过程中的突然停止;系统安装的控制器,利用速度控制算法,每次都以相同OEM(原始设备制造商)的连接参数,来保持一致、可重复的上扣作业。

Vero的内置软件功能可以自主评估与接受(或拒绝)更高准确度的连接:自动检测接头端部扭矩可提高连接精度,无需操作员手动调整数据;集成Vero软件根据OEM标准评估连接;故障排除顾问应用程序可确定上扣问题的根本原因,并建议纠正措施。

常规系统可以减少人力投入与体力劳动,以提高安全性并将风险降至最低:预先设置的参数取代了手动输入与现场操作员;测压传感器识别功能取代了人工输入测压传感器信息,这可以减少上扣扭矩过大或过小的可能性,并降低潜在的灾难性事故风险;安装在系统两侧的电子测压传感器,无需在接卸扣之间切换测压传感器,也无需重复性测量。

该系统将最新技术与成熟设备相结合,提供可靠的作业能力:包括远程查看上扣扭矩图,这取决于钻机的互联网连接;支持wifi的计算机系统可实现在井口值班房中的计算机上进行监控;可利用平板电脑等便携设备查看系统中的评估软件。

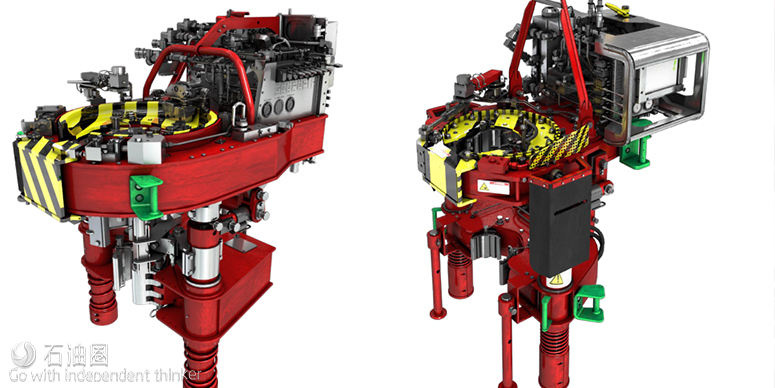

工具描述

常规系统自动控制上扣至最终扭矩,评估上扣数据的分辨率比人眼控制精确10倍。在连接上扣过程中,实时扭矩监控与自适应速度控制有助于调节扭矩和转速。这种精确控制与一致的评估,可提高可靠性与可重复性,从而降低油井完整性的风险。

该系统操作简单,缩短了学习时间,降低了作业人员的技能需求。操作者只需按下系统手柄上的一个按钮,即可进行最终的上扣作业。然后,系统会根据管道与丝扣OEM的标准,控制流程并进行上扣与评估。双向位移马达与液压阀部分,使该系统能够精确控制连接上扣速度。安装在系统上的平板电脑可显示扭矩/转圈图,指示系统状态,并可输入数据。

该系统还拥有实时访问的功能,可用于远程查看建井作业中产生的连接数据。该功能可实现异地远程监测,审查连接上扣图与系统软件的自动评估结果。

Vero机械化系统

Vero机械化系统通过计算机控制的精度,自动完成最终接卸扣,以提高效率与完整性:计算机编程与板载传感器使系统能够完成整个上扣工序,从高速旋转到最终上扣与评估,且无需来自操作者的输入或指示;系统安装的控制器,利用速度控制算法,每次都以相同OEM(原始设备制造商)的连接参数,来保持一致、可重复的上扣作业。

内置的Vero软件功能可以自主评估与接受(或拒绝)更高准确度的连接:自动检测接头端部扭矩可提高连接精度,无需操作员手动调整数据;集成的Vero软件根据OEM标准评估连接;故障排除顾问应用程序可确定上扣问题的根本原因,并建议纠正措施。

机械化系统减少人力投入与体力劳动,以提高安全性并将风险降至最低:凭借免手动的定位系统以及支持wifi连接的控制器,可以从控制室进行操作,从而远离钻台危险区域;预先设置的参数取代了手动输入与现场操作员;测压传感器识别功能取代了人工输入测压传感器信息,这可以减少上扣扭矩过大或过小的可能性,并降低潜在的灾难性事故风险;安装在系统两侧的电子测压传感器,无需在接卸扣之间切换测压传感器,也无需重复性测量。该系统将最新技术与成熟设备相结合,提供可靠的作业能力:包括远程查看上扣扭矩图,这取决于钻机的互联网连接。

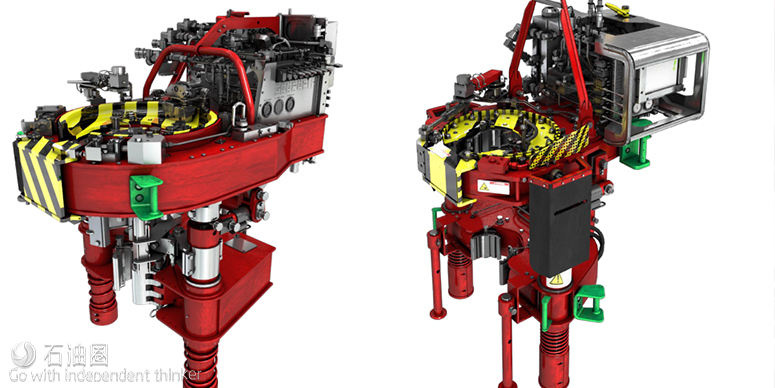

工具描述

机械化系统可用于大型海上钻井平台与钻井船的作业,通过管柱的自动接卸扣,以及自动评估管柱连接,来增强连接完整性。自动上扣可以精确控制作业过程,不受任何操作员的特定影响或其他人为因素的影响。自动评估消除了主观的图形解释。

机械化系统包括免手动的定位系统与遥控器。使用板载传感器与编程逻辑,系统管理整个上扣周期中的每个步骤,用于接卸扣的开始到结束。该系统还可以集成到钻机控制系统中,以提高作业效率,并可通过司钻椅进行控制。在连接上扣过程中,实时扭矩监控与自适应速度控制有助于调节扭矩和转速。这种精确控制与一致的评估,可提高可靠性与可重复性,从而降低油井完整性的风险。

该系统提供简单的免手动操作,从而降低了知识要求,并避免工作人员处于钻井平台的危险区域。操作者只需按下系统手柄上的一个按钮,即可进行最终的上扣作业。系统会根据管道与丝扣OEM的标准,控制流程并进行上扣与评估。双向位移马达与液压阀部分,使该系统能够精确控制连接上扣速度。集成的平板电脑与遥控系统可显示扭矩/转圈图,指示系统状态,并可从控制室输入数据。

For English, Please click here (展开/收缩)

Vero™ conventional system

Automates the makeupand evaluation, or breakout, of premium pipe,Connections on land and shallow-water rigs

Applications

- standard tubular strings

- premium, corrosion-resistant alloy (cra) tubular strings

- completion strings

Features and benefits

- the vero conventional system automates the final makeup and breakout with computer-controlled precision for enhanced efficiencyand integrity:

- – a speed-control algorithm uses continuous torque measurements, which signals the system to automatically slow down the makeup speed when approaching the optimum torque. These speed adjustments eliminate the need for a traditional dump valve and the corresponding sudden stops in the process.

- – a system-mounted controller uses a speed-control algorithm to maintain consistent, repeatable makeup to the same oem (original equipment manufacturer) connection parameters every time.

- the built-in vero software feature autonomously evaluates and accepts or rejects connections with improved accuracy:

- – automatic torque-shoulder detection increases accuracy, which eliminates the need for manual data adjustments by an operator.

- – integrated vero software evaluates connections according to oem criteria.

- – the troubleshooting advisor application identifies root causes of makeup issues and recommends corrective action.

- the conventional system reduces human input and physical work to enhance safety and minimize risks:

- – prepopulated parameters eliminate the need for manual entry and an on-site operator.

- – load-cell identification capability eliminates the need to manually

- Enter load-cell information, which reduces the possibility of overtorqued or undertorqued connections and potentially catastrophic failures.

- – electric load cells mounted on each side of the system negate the need to switch load cell connections between makeup and breakout and the redundancy of measurement values.

- the system combines the latest technologies with proven equipment to provide reliable access to operations:

- – remote-viewing of makeup graphs is included, which depends upon an internet connection on the rig.

- – wifi-enabled computer system makes monitoring possible on an additional computer in the doghouse.

- – zone 1 rated tablet enables viewing the evaluation software on the system

Tool description

Used for applications on land and shallow-water rigs, the weatherford vero conventional system enhances connection integrity by automatically making up or breaking out pipe and by autonomously evaluating pipe connections. Automated makeup enables precise control of the process, independent from any operatorspecific influences or other human factors. Autonomous evaluation eliminates subjective graphical interpretations.

The conventional system fully controls makeup to the final torque, and it evaluates makeup data with resolution 10 times more refined than the human eye can see on legacy screens. During the connection makeup process, real-time torque monitoring and adaptive speed control help to regulate the torque and

Revolutions per minute. This precise control and consistent evaluation increase dependability and repeatability to reduce well integrity risks.

The system offers simple operation, which shortens the learning curve and reduces the knowledge requirement for personnel. To initiate the final makeup process, the operator pushes a single button on the handgrip of the system. The system then controls the process and makes up and evaluates based on the pipe

And thread oem criteria. The dual displacement motor and hydraulic valve section enable the system to precisely control the connection makeup speed. A tablet mounted on the system displays a torque/turns graph, indicates system status, and enables data entry.

The system includes real-time access for remote viewing of the connection data produced during the well construction process. This access enables offsite monitoring and review of connection makeup graphs and autonomous evaluation results from the system software

Vero™ mechanized system

Automates the makeupand evaluation, or breakout,of premium pipe connections on large offshore rigs and drillships

Applications

- casing strings

- standard tubular strings

- premium, corrosion-resistant alloy (cra) tubular strings

- completion strings

Features and benefits

- the vero mechanized system automates the final makeup and breakout with computer-controlled precision for enhanced efficiency and integrity:

- – computer programming and onboard sensors enable the systemto complete the entire makeup sequence—from the high-speed spin in to the final makeup and evaluation—without inputs or signals from the operator.

- – a system-mounted controller uses a speed-control algorithm to maintain consistent, repeatable makeup to the same oem (original equipment manufacturer) connection parameters every time.

- the built-in vero software feature autonomously evaluates and accepts or rejects connections with improved accuracy:

- – automatic torque-shoulder detection increases accuracy, which eliminates the need for manual data adjustments by an operator.

- – integrated vero software evaluates connections according to oem criteria.

- – the troubleshooting advisor application identifies root causes of makeup issues and recommends corrective action.

- the mechanized system reduces human input and physical work to enhance safety and minimize risks:

- – a hands-free positioning system and wifi-enabled controller makes operation possible from the control room and away from the rig-floor red zone.

- – prepopulated parameters eliminate the need for manual entry and an on-site operator.

- – load-cell identification capability eliminates the need to manually enter load-cell information, which reduces the possibility of overtorqued or undertorqued connections and potentially catastrophic failures.

- – electric load cells mounted on each side of the system negate the need to switch load cell connections between makeup and breakout and the redundancy of measurement values.

- the system combines the latest technologies with proven equipment to provide reliable access to operations:

- – remote-viewing of makeup graphs is included, which depends upon an internet connection on the rig.

Tool description

Used for applications on large offshore rigs and drillships, the weatherford vero mechanized system enhances connection integrity by automatically making up or breaking out pipe and by autonomously evaluating pipe connections. Automated makeup enables precise control of the process, independent from any operatorspecific influences or other human factors. Autonomous evaluation eliminates subjective graphical interpretations.

The mechanized system includes a hands-free positioning system and remote controller. Using onboard sensors and programming logic, the system manages each step in the entire makeup cycle, from the closing to the opening of the door for both makeup and breakout. The system can also be integrated into the rig controls to increase the operational efficiency and to enable control through the driller’s chair.

During the connection makeup process, real-time torque monitoring and adaptive speed control help to regulate the torque and revolutions per minute. This precise control and consistent evaluation during the connection makeup process increase dependability and repeatability to reduce well integrity risks.

The system offers simple and hands-free operation, which reduces knowledge requirements and eliminates personnel from the rig-floor red zone. With just a single click from the control room, the operator starts the makeup cycle. The system controls the process and makes up and evaluates based on the pipe and thread oem criteria. The dual displacement motor and hydraulic valve section enable the system to precisely control the connection makeup speed. The integrated tablet and remote control system displays a torque/turns graph, indicates system status, and enables data entry from the control room.

The system includes real-time access for remote viewing of the connection data produced during the well construction process. This access enables offsite monitoring and review of connection makeup graphs and autonomous evaluation results from the system software

未经允许,不得转载本站任何文章:

石油圈

石油圈