Predictive analytics, the Internet of Things, artificial intelligence—these are not just buzz words anymore—they are digital, automated technologies rapidly transforming the oil and gas industry.

What has changed today across exploration and production is the number of different elements that can connect to each other, the way data are shared and transferred and, most importantly, the speed at which these data are translated into actionable insights for operators. This digital transformation is changing the way that we do business, offering new and more powerful ways to connect to the reservoir, operations and equipment (on the surface and downhole), and have closer collaboration with each other.

Halliburton is accelerating this digital transformation by implementing systems and architecture that enable smarter decision-making across the well construction life cycle. At our core, we have implemented an enterprise architecture that integrates systems, applications, big data analytics, advanced modeling, and workflows from multiple applications. In the field, we execute drilling operations according to a specified well plan and predetermined drilling parameters.

Advances in sensor technology, downhole processors for complex, large-scale computations, and high-speed telemetry systems allow for systematic real-time data processing and analysis, at both the surface and downhole—at a rate and accuracy that cannot be matched by human operators. Machine learning and data analytics, coupled with sophisticated algorithms, can help field and real-time operation center (ROC) experts analyze drilling conditions in real time, optimize the drilling plan accordingly, and make smarter decisions at the rig site.

By automating the drilling process, we can help operators maximize asset value through reduced non-productive time (NPT), fewer rig site personnel, and lowered costs per barrel of oil equivalent (boe) while delivering predictable, dependable and consistent results.

SMART DESIGN MEETS DRILLING AUTOMATION

Optimization of the well plan requires smart, advanced surface and downhole systems that capture data in real time, and send continuous commands to adjust for current drilling conditions. At the center of directional drilling automation lies the new iCruise intelligent rotary steerable system (RSS), designed to help operators place wells accurately, reduce well time, improve reliability, and achieve predictable results.

This intelligent push-the-bit system features advanced electronics for tool prognosis and diagnosis, multiple downhole sensors, high-speed processors for complex computations, and distinct survey packages to assess drilling conditions in real time. Multiple high-bandwidth sensors continuously measure downhole vibrations and annulus pressure, as well as borehole inclination and azimuth, which help predict unforeseen trends and enable more accurate well placement. Additionally, the modularity of the system helps operators to meet all drilling challenges, from long laterals to high-curvature sections—up to 18°/100 ft—in unconventional, deepwater or mature fields.

The intelligent RSS system is matched with the GeoTech (GTi) drill-bit series, Fig. 1. It is engineered with design software around the drilling parameters, formation properties, drill bit cutting structure, and gauge configuration, to optimize the side-cutting efficiency (SCE) of the bit, leading to improved steerability and drilling performance in all formation types. The bit also can record high-frequency vibration and motion data, to provide further information of downhole performance.

ACHIEVING CONSISTENT, PREDICTABLE RESULTS

The intelligent RSS system is integrated with the automated drilling advisor software, which helps directional drillers make informed and efficient drilling decisions around directional control and vibration management. Based on physics models of the BHA and drill bit, machine learning of real-time data is used to augment these models, to define current drilling conditions and predict future well uncertainties.

The automated drilling advisor also can compute the optimal series of steering commands (duty cycle and tool face) to steer successfully along the planned wellbore trajectory, land the curve, and reach target depth. Its ability to identify formation tendency, estimate current and future tool outputs, and adapt to changes in the coming trajectory, allows it to mitigate borehole tortuosity while building a sufficient safety margin. This ensures smooth landing of the curve and reaching the planned target accurately and consistently.

Sophisticated algorithms are also incorporated within the system, which perform analyses downhole. These algorithms already make decisions without human interference. Control algorithms maintain constant inclination and azimuth of the borehole, while others process sensor data to identify the type, frequency and intensity of downhole vibrations, and communicate the information to the drilling advisor for automated mitigation actions.

The automated drilling advisor also provides consistent interpretations and analyses, post-run, that can be projected systematically to future operations. It automatically transfers knowledge to derive consistent and dependable insight across wells and basins, therefore helping operators obtain predictable results for future asset development.

AN INTEGRATED APPROACH TO DRILLING AUTOMATION

The intelligent RSS system and the automated drilling advisor are only two pieces of the push toward a fully integrated, drilling automation platform. In geosteering applications, the EarthStar ultra-deep resistivity service and its geosteering software establish a two-way communication with the automated steering advisor. Geosteering targets are sent directly to the automated drilling advisor, to automatically steer the RSS toward the desired objective while providing experts with real-time information for more-informed decisions on borehole trajectory.

Fluid management and monitoring are also an integrated part of the well construction workflow. At the surface, we no longer have mud engineers manually measuring fluid parameters once or twice per day. Today, the BaraLogix real-time and automation unit measures and sends fluid data 100 times per day. The data captured are density and rheology, which are sent to the real-time fluid application being monitored at the real-time centers. There, engineers can now see and predict a wellbore stability issue ahead of time, helping operators save rig time and costs.

Well construction beyond that of just wellbore placement is also important. When incorporating managed-pressure-drilling (MPD) systems, the wellbore pressure is managed at the speed of sound by controlling the wellhead pressure through wellbore hydraulics models. These models are calibrated with pressure-while-drilling (PWD) data, in real time, and the MPD system’s advanced algorithms. The MPD system is designed to listen to the RSS commands and adjust the bottomhole pressure accordingly, when downlink commands are sent to, and data are received from, the tool. It also utilizes real-time density and rheology data, and compares these calculated results to the PWD measurements for a real-time early wellbore event system.

Because the intelligent RSS directional capabilities depend on the flowrate and density of the drilling fluid, the integrated nature automating the well construction workflow is essential. With more analytics and sophisticated algorithms added downhole, and at the surface, the burden of decision-making is shifted progressively from field personnel to automation services that work together to drive the full drilling process. Our company combines digital solutions to automate the well construction process, helping operators maximize asset value through improved recovery, reduced well time and risks, and lower costs per boe.

CASE STUDY 1: MAXIMIZING LATERAL WELL CONTACT

An operator in the U.S. had to maintain the wellbore within a 30-ft-thick reservoir. The combination of sensor measurements from the iCruise intelligent RSS, particularly the at-bit inclination, and the deep-resistivity tool provided reliable data to geosteering experts for efficient directional guidance, to maintain the borehole in the lower half of the reservoir. At the same time, the automated drilling advisor provided directional drillers with clear recommendations regarding how to steer toward targets while accounting for local formation push. The vendor helped the operator place the well accurately by remaining 100% in zone and reduced well time by delivering consistent and predictable results, thereby maximizing the value of the asset run.

CASE STUDY 2: ACCURATE WELL PLACEMENT IN A LONG LATERAL

Halliburton drilled a lateral section at 9,644 ft with the intelligent RSS, and stayed with a 15-ft window within plan, landing the well within 1 ft of the true vertical distance (TVD) of the target. This was achieved while keeping the borehole curvature below 2°/100 ft during the entire run, helping the operator to place the well accurately and achieve maximum reservoir contact.

CASE STUDY 3: LANDING A HIGH DOGLEG CURVE

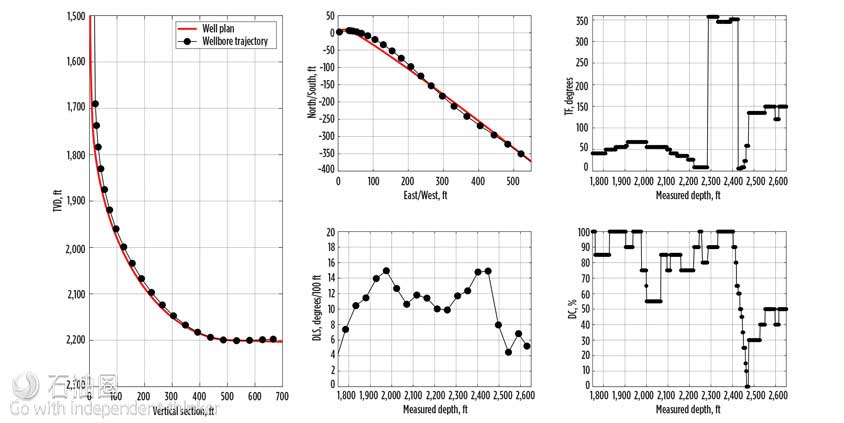

A full curve—with a curvature of 12°/100 ft—was drilled using the iCruise intelligent RSS by following the recommendations of the automated drilling advisor. After kickoff, the advisor was able to maintain a sufficient safety margin and then landed the well accurately, as planned. A physics-based model is used to simulate tool performance. The projected well trajectory is adapted in real time, relative to the current output of the BHA, while optimizing steering decisions in real time to reduce borehole tortuosity.

石油圈

石油圈