Subsea boost pumps and long-distance power and communication capabilities have enabled Chevron to execute longer tiebacks in the deepwater US Gulf, allowing the company to extend its reach and further leverage existing infrastructure, Jay Johnson, Executive Vice President Upstream Chevron, said during the company’s 2018 Security Analysts Meeting, held on 6 March in New York.

“We’re lowering our cost in deepwater through efficiency, technology and standardization,” Mr Johnson said. As a result of this strategy, Chevron has reduced its well completion time in the US Gulf by more than 40% since 2014.

For future developments, all-electric subsea infrastructure and self-managing wells are field development solutions that are being considered.

“Operators are looking at how to handle more demanding operations with fewer people handling equipment – not only reducing HSE risks but also the cost of flying workers to and from offshore platforms,” Jim Sessions, Vice President of Sales and Commercial for the Completions and Well Intervention product line at Baker Hughes, a GE company (BHGE), said. Further, improvements in streaming video and audio capabilities will allow subject matter experts to consult from central onshore facilities and monitor platforms, according to Mr Sessions.

However, additional development of subsea technologies – specifically the creation of low-cost, robust seabed generators and transformers for the separation of oil and water – is needed before subsea factories will become more widespread.

“Due to cost, full subsea processing field development will only be conducted on select offshore fields,” Mr Martinsen said. “As oil prices recover, operators will start to think in terms of those lines and develop that business case better.”

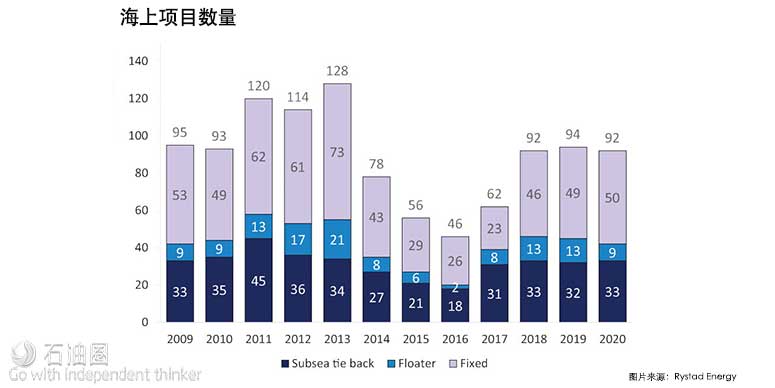

Rystad expects to see more conventional subsea developments taking place over the next five years, such as wells tied back to floating production storage and offloading vessels.

Pure subsea tiebacks are more lucrative for operators because their investment can be recouped within five years, as opposed to a decade for traditional offshore field development. Subsea projects can also better compete financially with the short cycle times of onshore shale developments.

Within the next five to seven years, the industry will most likely look to pure subsea factories – as long as oil prices are high enough to support them.

“If they succeed on that, that would unlock Arctic subsea development because they won’t have surface exposure to icebergs,” Mr Martinsen said. Rystad estimates that oil would need to remain around the $70/bbl mark to make these sorts of unconventionals attractive.

Setting Production Packer Without Intervention

To meet operators’ subsea completion needs, National Oilwell Varco (NOV) continues to develop technologies that increase efficiency and reliability. Earlier this year, the company conducted field trials of its packer-setting system featuring the i-Seat ball, the latest innovation from its d-Solve dissolvable platform. The integrated system allows a production packer to be set without intervention, eliminating the need for multiple slickline or wireline tractor runs.

The technology is deployed by installing a profile below the production packer, then deploying the dissolving ball, which is designed to hold pressure for certain amounts of time. The ball dissolves over time, allowing well production to be started without having to remove a plug. To help the balls dissolve in the presence of chlorides in the wellbore fluid, NOV selected a combination of metallic materials, Tom Kol?y, Regional Head of Sales for NOV’s Completion Tools business unit, said.

NOV worked with a North Sea operator during the field trials to eliminate the cost and risk associated with the wireline and tractor run involved in setting production packers and removing the equipment prior to well startup. A typical packer-setting operation involves a wireline run to pull the downhole safety valve hold-open sleeve; a tractor run to pull the check valve below the production packer; and a wireline run to set and pull a shallow set plug.

For the trial, the operator needed the dissolvable ball solution to hold 5,000 psi for 30 minutes, then pass through the ball sub within 24 hours. In a comprehensive full-scale testing and qualification program performed in simulated downhole conditions, the solution was qualified to the required conditions and operating range.

The packer-setting kit has been run on three wells since August. All have been successes, and the tubing and annulus test confirmed that the packer had been set. Using the combined NOV technologies eliminated the requirement for up to six days of rig time per well versus operations typically involved with conventionally set production packers. It also eliminated the cost and risk associated with typical packer-setting operations. The solution can also be run as a contingency setting method for hydrostatic set packers.

“In the North Sea, those rigs typically cost anywhere from $200,000 up to $300,000/day, so saving six days of rig time is considerable as our clients strive to complete more efficient wells,” Mr Kol?y said.

Additionally, NOV is working with a major North Sea operator to jointly develop the ReAct completion circulation valve, a remotely operated circulation device run above the production packer to enable more efficient subsea completion processes. The operator has plans to install the valve technology on one of its larger subsea developments in 2019. The valve can be deployed above any packer and is run in the closed position to allow for packer setting and packer/tubing testing. The design allows bypass of up to six control lines for gauges, control valves and other downhole equipment. Once the packer is set, the operator can pressure-test the tubing against the closed valve.

Applying increased annulus pressure opens the ReAct completion circulation valve to allow communication between tubing and annulus. Heavy fluid can then be circulated out to a light fluid, allowing the well to flow naturally once put on production. The application of a pressure signal to the onboard ReAct module signals the valve to close. After a pressure test, the well can be put on production.

“Basically, we are combining a mechanical sliding sleeve with electronic pressure gauges to create the ability to remotely signal the mechanical device to perform certain operations,” Mr Kol?y said. “We are signaling it from the surface to open up, then pumping light fluid down the tubing to remove heavy fluid in the completion. Then we signal to the tool to close.”

Although many subsea projects still fall into the standard pressure and temperature category, NOV is also developing HPHT solutions, 15K pressure-rated systems, and the infrastructure to obtain real-time subsea completions data through the company’s wired drill pipe technology.

Subsea Safety is Paramount

Not only must subsea completion technology meet the industry’s need to reduce costs while boosting efficiency, but it also must maintain safe operations. In 2019, Halliburton will release updated versions of its VETO direct hydraulic and DASH electrohydraulic large-bore subsea safety systems for well completions.

Both systems are run with either horizontal or vertical subsea production trees and integrated with the tubing hanger running tool to allow for control of a well’s upper completion. The two technologies are offered as 6 3/8-in. systems rated to 15,000 psi and 7 3/8-in. systems rated to 10,000 psi.

VETO direct hydraulic subsea safety systems let operators conduct well tests, deploy completion and perform workovers. The system consists of a subsea test tree, a retainer valve, a lubricator valve, as well as other ancillary parts comprising a standard subsea landing system.

In shallow-water operations, the VETO system controls the umbilical from the surface using direct hydraulics. Because deeper waters require longer umbilicals, which delays response times, the 7 3/8-in. system is fully compatible with the company’s DASH electrohydraulic controls.

For deepwater, the system is used to control the umbilical by converting the command to shut in a well into an electrohydraulic response using an electric cable.

The system can also shut in production from subsea wells in emergencies in as little as six seconds and conduct an emergency quick disconnect within 10 seconds. Currently, industry best practices are around 15 seconds, Richard Broad, Subsea Strategic Business Manager with Testing and Subsea at Halliburton, said. The system also allows for real-time data and sensory understanding of what’s happening.

“So instead of using an 8,000- to 10,000-ft umbilical to communicate and operate the tools, we are now taking that control to the tool regardless of water depth, basically on top of the tool itself, while uniquely still providing full direct hydraulic redundant control of all functions. This increases system reliability and provides cost-efficient operations,” he said.

Electrohydraulic controls can be used for well shut-ins during emergency conditions, such as adverse weather, loss of positioning or a well control situation where an emergency barrier must be placed in the wellbore, ultimately closing the subsea test tree.

Through linking with downhole and surface read-out control, the system can enable analysis for optimal performance to avoid nonproductive time, maximizing efficiency during complex deepwater completion landing string operations. The system delivers a high speed of response to critical well isolation, as well as pressure containment and emergency disconnect functions.

The combination of the VETO and DASH technologies provides insights into the BOP to check pressure, temperature, orientation, inclination and tension across systems. By using a sensor sub, the position and orientation of the completion landing string relative to the BOP and tubing hanger, tension compression of up to 100 lb, and the torque within the string can be actively monitored in real time.

Halliburton conducted a field trial of its DASH system in November and December 2016 in the US Gulf of Mexico, where an operator needed to plug and abandon two deepwater wells.

The company was able to deliver a fully customized solution using the DASH completion landing string in less than 30 days after conducting a full electrohydraulic system integration test in four days. A comparable hydraulic subsea safety system would have taken more than three months. No safety issues occurred, and no nonproductive time was incurred during the trial.

Halliburton’s next step is to further develop the two technologies, Mr Broad said. This continues the theme of modularization and lowering the overall complexity of system and controls to of reduce operational rig time, minimizing risk and maximizing the customer’s asset value.

石油圈

石油圈