If marginal offshore fields are to become economic, the next wave of subsea completion solutions must continue to focus on lowering costs and boosting efficiencies.

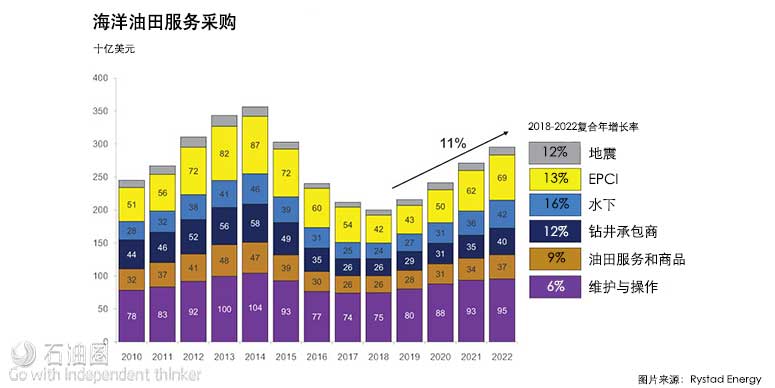

As oil prices recover and operators are successful in their efforts to reduce offshore field development costs, the amount of subsea equipment orders is expected to rise in 2019. In fact, for the foreseeable future, spending on subsea equipment is expected to increase, according to an analysis of industry trends from Rystad Energy. Demand for subsea equipment will come from major field development projects, such as Shell’s Vito project in the US Gulf of Mexico and Equinor’s Johan Castberg field offshore Norway.

“Of course, then you have lots of small development, and also brownfield projects, where operators didn’t want to replace subsea infrastructure and drill incremental wells during the downturn,” Audun Martinsen, Partner and Head of Oilfield Services Research at Rystad, said. “Now that we are seeing oil prices at $70/bbl or $80/bbl, instead of $40/bbl or $50/bbl, it makes sense to drill another well and buy another piece of subsea equipment to complete the well.”

Subsea boost pumps and long-distance power and communication capabilities have enabled Chevron to execute longer tiebacks in the deepwater US Gulf, allowing the company to extend its reach and further leverage existing infrastructure, Jay Johnson, Executive Vice President Upstream Chevron, said during the company’s 2018 Security Analysts Meeting, held on 6 March in New York.

Forming Electric Subsea Well Completions

BHGE has focused on subsea completions technologies that lower lifting costs for wells in higher-pressure, higher-temperature reservoirs. They aim to make field development projects economic at lower oil prices and will ultimately come together to form electric subsea well completions. However, these technologies won’t be deployable until after 2019, Mr Sessions said.

“The intent is you can take not just a well but a field, and you can pull in data to monitor the field’s health,” Mr Sessions said. “Production versus injector wells can be monitored, production in different parts of the field regulated and well zones closed off or opened up. What you have is field optimization without any intervention.”

To address operator challenges surrounding subsea completions, BHGE plans to release several technologies throughout 2019. For the reservoir, the company has developed GeoFORM – a sand management solution that uses an advanced shape-memory polymer technology to conform to complex well profiles, multilaterals and ultra-fine sand formations. Its polymer technology enables operators to produce from long, zonal intervals of 1,000 ft to 3,000 ft of reservoir, while preventing sand migration into the wellbore. This allows for more sustainable production with significantly reduced risk during installation, and eliminates voids in conventional gravel packs.

The technology also eliminates the need for typical gravel-pack operations, which can involve a crew of 10 engineers and field specialists, as well as specialized blending and pumping equipment.

“Fluid always takes the path of least resistance and will flow up through the annulus until it hits a packer or obstruction, causing the majority of the production to enter the wellbore at a single spot,” Mr Sessions said. “What happens is you have a massive flow through a concentrated area, which can cause erosion and loss of sand control.”

If sand gets into the well, it can destroy tubulars, as well as surface equipment or infrastructure, he added. Traditionally, gravel is packed across the reservoir to eliminate annular production flow and sand erosion to prolong the integrity of the well and surface equipment. However, gravel packing is a time-consuming process that also requires significant pumps and other surface equipment.

The expanding polymer works by being heated and compacted to a smaller outside diameter (OD) size compared with a wellbore. The polymer material is then placed onto a perforated base pipe and deployed downhole. After the polymer is sent into the well, an activation agent is pumped down, which triggers the polymer to return to its original OD.

When the material returns to its larger diameter, it forms a tight seal against the wellbore, providing total conformance, regardless of any hole irregularities. The polymer maintains a positive stress against the formation, which stabilizes the near-wellbore region.

Field trials of GeoFORM, conducted at three offshore gas wells across five production zones in several water zones, resulted in a 40% reduction in rig time, compared with the time required for a conventional cased-hole frac-pack operation. The trials also showed that, by enabling higher production, the operators were able to achieve an estimated cost savings of $5 million per well, according to BHGE.

From an efficiency perspective, the company believes the technology will be a game-changer, particularly in remote areas where the infrastructure doesn’t exist for pumps and crews to be mobilized, Mr Sessions said.

“What’s significant is you no longer have to gravel-pack these wells, and a special intervention tool is not needed,” he added. “That means there’s significant cost savings for operators. Better reservoir contact also can be achieved through more even coverage of the reservoir.”

Since the new system is relatively simple to use, heavy expertise is not needed at the surface for deployment, he noted. The move toward simplicity is a common theme in today’s subsea environment and in the oil field in general, Mr Sessions said.

In addition, the adoption of big data strategies – coupled with emerging technologies, like artificial intelligence and self-learning algorithms – are enhancing subsea completion solutions. The ability to delve into terabytes of well data represents a major opportunity for the oil and gas industry, according to Mr Sessions.

Still, despite the plethora of information provided on a daily basis, the oilfield still has “a lot to learn in terms of data analysis,” Mr Sessions said. Data harvesting is the first step, but how the industry takes this data and turns it into executable actions to improve efficiency, reduce risk and improve production is the future.

“As the oil and gas industry recovers from the 2014 oil price crash, the technology bells and whistles once mandatory as selling points are today perceived as an extra element of risk,” Mr Sessions said. “Today, it’s more about fit-for-purpose design without extras. We just need to continue that trend of simplicity … and figure out how to better utilize data analytics, software and IT infrastructure that what we have at our disposal.”

Less Intervention, Fewer Umbilicals

Reducing cost of capture, increasing reliability and deployment flexibility, and preparing for the digital oilfield are drivers behind the development of subsea completions technology at Schlumberger, according to Steve Dyer, Technology Manager for Reservoir Monitoring and Control for the company’s completions portfolio.

To simplify subsea well completions and start-ups with less intervention and fewer umbilicals, Schlumberger developed the Proteus electrohydraulic downhole flow control and monitoring system. It is expected to reach the commercial market in 2019.

The system enables monitoring and control of up to nine well zones with only two hydraulic lines and one electrical line, depending on the well configuration. The electrical line delivers data from pressure and temperature surveillance sensors and controls the actuation of the flow control valves so that an interval producing unwanted water or gas can be choked back without disrupting production from other intervals. Individual zones or compartments can be dynamically tested without intervention, minimizing the impact on production.

The system combines a downhole control module, dual pressure and temperature quartz gauges, a field-proven control valve, and an absolute position sensor in a single compact assembly. The position sensor directly measures and manages the choke position unit and is controlled from surface using a user-friendly operating system.

The system has been enhanced for subsea and allows the multi-dropping of flow control and ball isolation valves, or barrier valves, on the same electrohydraulic umbilical.

Typically, hydraulic or electrical umbilicals are run and clamped to the outside of a wellbore’s tubing. For conventional control systems, each time a control device is installed, at least one more umbilical must be added for each well zone. Each time a connection is added, more splices – or a connection between two umbilicals – must be made. The system greatly reduces the number of lines, clamps and splices, making running in the hole a smoother and more efficient operation.

“Traditionally, intelligent completions have been limited to two zones in a subsea environment, using a combination of annular and in-line, or shrouded, flow control valves,” Mr Dyer said. “While exceptions do exist –there is an extensive track record of three- and four-zone subsea intelligent completions in the North Sea, for example – the cost, time and risk associated with running, splicing and testing additional umbilicals have remained a deterrent. But we are confident we have now removed that hurdle.”

In a field trial of the technology, in a dry tree application, Schlumberger helped an operator monitor and rapidly control production flow from each leg of a multilateral well, while minimizing completion complexity.

The trial was conducted in the Middle East, and it showed that the technology could be used to complete up to five zones with only three control lines instead of six, saving almost two days of rig time. The operator also saved 3.6 hours of rig time in cycling all well zones, compared with the 45 to 50 minutes per zone required to actuate conventional hydraulic flow control systems. On top of these installation and operational time savings, the well has produced for more than 2.5 years with no issues, according to Schlumberger.

石油圈

石油圈