The multi-partner study has been initiated by FPSO (Floating Production, Storage and Offloading) and Subsea specialists, Crondall Energy, who developed the technology and will be led and managed by Crondall’s subsidiary, Buoyant Production Technologies Ltd.

The study is funded by Crondall Energy, the Oil & Gas Technology Centre and a host of industry sponsors including Premier Oil, Total E&P UK, Lloyds Register, Siemens, Wärtsilä, Ampelmann and BW Offshore.

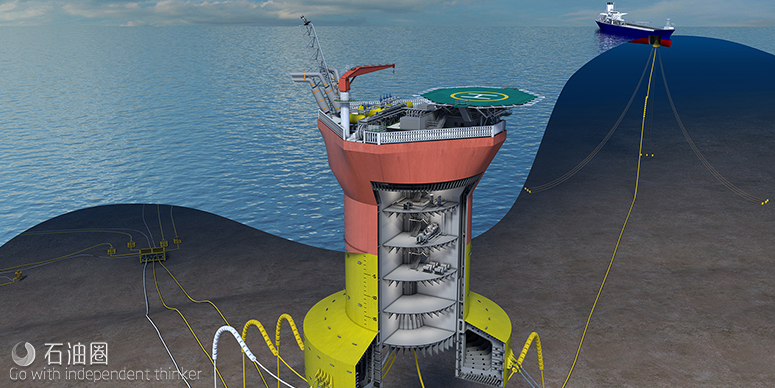

It will explore the feasibility of a floating Normally Unattended Installation (NUI) as a stand-alone oil production facility for marginal fields in a North Sea environment and kicks-off the Technology Centre’s recently-announced ‘Facility of the Future’ initiative.

Speaking after the study’s kick-off session at the Technology Centre, Duncan Peace, Managing Director of Crondall Energy said: “New process and automation technology is playing a critical role in reducing the size and cost of offshore facilities and reducing the offshore man-hours required for their operation and maintenance. What makes our concept unique is the integration of these process and automation technologies with Crondall’s patented floating production concept, to deliver a material reduction in both the size of facilities and the level of manning. Together these innovations offer the opportunity to deliver a step change in lifecycle economics.

“The diverse group of industrial sponsors brings a wealth of expertise and insights to the table and we’re excited to be able to work with them to improve the economics of offshore developments. The support we’ve had from the Technology Centre and from our sponsors has been crucial in helping get the study underway and we look forward to continuing to work with them.”

The project aims to confirm that such technology can meet the requirements of remote operations with acceptable uptime and maintenance requirements.

The NUI concept developed by Crondall Energy could be used with subsea wells, to provide the production facilities and utilities required to exploit a field.

The partners will evaluate a generic opportunity for a field in the Northern North Sea, in 150m water depth, producing 20,000 barrels of oil per day with a low to medium gas oil ratio. They will also evaluate how the lessons learned from this case study can be applied more widely in the development of North Sea marginal fields with, for example, a minimally manned compact FPSO.

The joint-industry review, will widen the application of NUIs and demonstrate that they can offer improved performance and lower life-cycle costs.

Chris Pearson, Marginal Discoveries Solution Centre Manager for the Oil & Gas Technology Centre, said: “Marginal discoveries represent a significant opportunity to maximise economic recovery from the UKCS, but we need a new, smarter approach to field developments if we’re to make it a reality. We’re excited to be working with Crondall and our industry partners on the study, which will help transform the future of the oil and gas industry and those working in it.”

The study will be conducted in two phases over eight months, evaluating the technical and commercial feasibility of the concepts developed.

Lorenz Nehring, Ampelmann Operations (UK) for Ampelmann, said: “Ampelmann are very excited to be part of this project. What’s crucial for the Facility of the Future is ensuring certainty in being able to deliver personnel or cargo you have particularly given the North Sea weather. Ampelmann, through its extensive experience has provided safe, efficient and reliable transfers for over 11 years, with a 99.6% technical reliability and ability work in sea states of over 4m Hs.”

“We have safely transferred more than 4.4 million offshore workers and over 8 million kilograms of cargo worldwide to offshore O&G platforms, wind turbines, FPSOs and other fixed or floating structures at sea. Innovation is key to maintaining the MER momentum. We are looking forward to participating further in this project.”

Siemens’ participation in this study provides an opportunity to demonstrate the benefits of its Topsides 4.0 digital life cycle approach to rotating equipment and to electrical, instrumentation, controls and telecoms (EICT).

“On the one hand, there has been a lot of hype about digitalisation in the oil and gas industry; on the other hand, oil and gas operators are still waiting to be convinced,” said Elgonda La Grange, Director of Digital Solutions for Siemens’ Dresser-Rand business. “This study will demonstrate the lifecycle value of combining digitalization with deep O&G subject matter expertise. We are excited to be part of this initiative which we believe has the potential to change the mindset of the offshore O&G industry.”

Wärtsilä’s participation in this study is very much in line with its Smart Marine Ecosystem vision, which foresees a future where a smart, connected and digitalised approach sets new standards for the entire industry.

“A smart installation with remote operation ensures optimum use of equipment, a NUI installation will also enhance safety and provide minimal environmental impact,” says Stein Thorsager, Sales Director, Floating Production, Wärtsilä.

石油圈

石油圈