The most efficient field frac network starts with predictable frac spacing and predictable propped volume. Multistage Unlimited frac isolation delivers both. Add downhole data recording and you have repeatable frac-delivery that helps you adjust and evaluate frac spacing and frac design for subse- quent wells. Plug-and-perf completions, on the other hand, are not predictable, verifiable, or repeatable, and they provide no downhole data for use in optimization.

An ideal field frac network would comprise equally spaced fracs of equal propped volume resulting in the maximum number of stages without interzone communication and maximum frac length and height without bashing other wells or poaching other formations. Optimization means getting as close to the ideal as possible as long as it makes economic sense.

Features and benefits overview

- Unlimited stages and spacing

- Easy-to-run sleeves

- No rig-up/rig-down between stages

- Downhole data acquisition

- More effective proppant placement

- Quick screenout cleanup

- Unrestricted, production-ready wellbore

- Two-thirds less pumping horsepower

- Less equipment at the wellsite

- Less water, less chemicals

- Less environmental impact

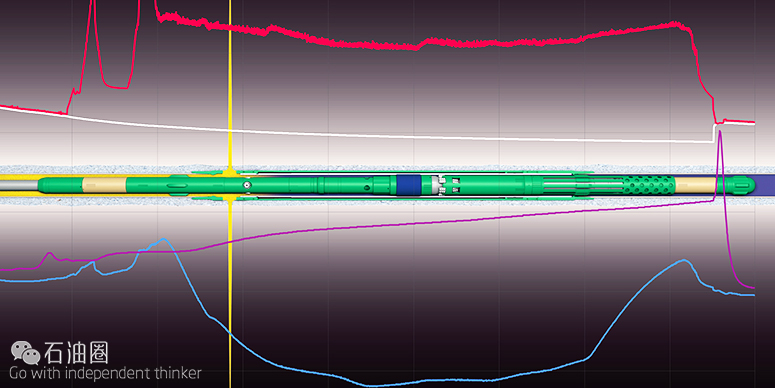

The Multistage Unlimited system

Frac sleeves

Multistage Unlimited frac sleeves deliver all the benefits of predictable frac spacing and predictable propped volume, along with a nonstop frac operation. With their unrestricted ID, the sleeves permit normal cementing operations, and they do not impede production or future well intervention. The sleeves are built to match the host casing, have high-torque capabil- ities, and are shipped with pre-torqued pup joints for easy handling and make-up into the casing string.

Resettable bridge plug

The Multistage Unlimited resettable frac plug has three functions: isolate the frac zone from the hole below, grip the sliding sleeves for shifting, and anchor the isolation assembly during frac pumping or sand-jet perforating. It incorporates an automatic J-slot mechanism that sets, releases, and resets the tool with straight up/down coiled tubing motion. The bridge plug’s proprietary seal material, construction, clearances, and self-flushing design make it extremely sand-friendly and reliable for frac operations. An integral equalization valve facili- tates releasing the bridge plug under high differential pressures and also enables reverse circulation.

Sleeve locator

The robust, one-piece mechanical sleeve locator has a profile that matches a recess at the bottom of the sleeves. As the frac-isolation assembly is pulled up through the sleeve, the keys snap into the recess. The instant increase in overpull is positive surface indication that the assembly is properly posi- tioned inside the sleeve.

Data recorders

There are two data recorders on each downhole assembly, one above the resettable bridge plug and one below. These precision gauge/recorders measure pressure both inside the tool string and in the coiled tubing/casing annulus, temperature and linear forces. The data is used for verifying stage isolation and for diagnostics.

Sand-jet perforating sub or flow sub

Sand-jet perforating is used to add stages in blank casing. It is also used in lieu of sliding sleeves when the well is already cased. The perforating sub also enables forward circulation. When the completion incorporates MultiCycle sleeves, a simple flow sub replaces the perforating sub, because perforations defeat the purpose of the reclosable sleeves.

MultiCycle sleeves: a new way to frac, and more

New MultiCycleTM frac sleeves (shown on opposite page) deliver unprecedented options for completing a well, managing produc- tion and secondary recovery operations, and performing refracs or other remediation. Now, you can fracture stages out of sequence, and you can close and reopen selected intervals as needed over the life of the well. For completions, the frac-isolation assembly locates the sleeve, isolates the stage for stimulation and shifts the inner barrel down to open the frac ports. The sleeve can be closed after the frac by pulling on the coiled tubing. During production or remediation, a similar tool locates the sleeve for reclosing and reopening as required.

MultiCycle sleeves offer a number of new capabilities:

- Prefrac injection test along the lateral, not just at the toe

- Prevent proppant inflow after a frac, while frac heals

- Frac stages in any desired order, exploit stress shadowing effects

- Shut off water production, unwanted gas, and thief zones

- Manage waterflood or other EOR

- • Restore wellbore integrity for refracs

Half-Straddle option for low-rate fracs

The Half-StraddleTM option is ideal for completions in thin forma- tions with water-bearing zones nearby. These wells are usually best completed with a large number of stages and smaller frac- tures to avoid the water zones. The lower frac rates (10 bpm or less) are pumped through the coiled tubing instead of the coiled tubing/casing annulus.

It’s called the Half-Straddle option because it resembles a coiled-tubing straddle with only a lower seal; the upper seal is achieved by closing the annulus at the surface.

Whenever the Half-Straddle option can be used, it provides three important advantages:

- It reduces water consumption even more—up to 50% compared to plug-and-perf and ball-sleeve systems.

- Low frac rates and volumes help control frac growth.

- There is no need for a high-pressure wellhead stack because the coiled tubing contains all frac forces.

The only equipment difference between the Half-Straddle and the Multistage Unlimited annular-frac system is the addition of a frac valve above the resettable bridge plug. The sub permits fracs to be pumped down the coiled tubing and out the sleeve ports.

A ball-seat feature allows flow to be diverted temporarily through the sand-jet perforating sub to add stages in blank casing. After perforating, the ball is pumped through the ball seat, and the frac is pumped down the coiled tubing.

Sand-jet perforating

Multistage Unlimited zone isolation with sand-jet perforating uses a high-velocity abrasive slurry to cut perforations to access the formation. This option is used to add stages on the fly or for completions when a well is already cased.

Typical completion

The frac-isolation assembly functions the same as with Multistage Unlimited sleeve systems. The completion begins at the toe of the well, with the frac-isolation assembly positioned at the lowest planned stage. The resettable frac plug isolates the zone from the well bore below and anchors the assembly. Then abrasive slurry is pumped through the perforating sub nozzles. High-velocity jets cut through the casing and cement and into the formation in approximately 45 minutes.

When the perforations are complete, frac pressure is applied down the annulus. As with Multistage Unlimited sleeve com- pletions, the coiled tubing serves as a deadleg, providing actual pressure at the frac point to assist in adjusting sand concentration and ramp, fluid viscosity, and pump rate in real time.

Peforating parameters are matched to formation characteristics and coiled tubing length and size. Parameters include slurry densi- ty, slurry flowrate, slurry pressure, and cutting duration.

With planning and coordination, stages can be completed quickly and smoothly. After the last stage, the isolation assembly is re- trieved, and the full-open wellbore is ready for production.

石油圈

石油圈