Horizontal wellbores are open favored by operators for exploiting narrow, oil-bearing formations to maximize contact with the pay zone. However, when production causes unwanted gas and/or water to migrate to the wellbore or uneven production distribution results due to pressure drop in the tubing, operators turn to Halliburton’s EquiFlow? autonomous inflow control device (AICD) to both delay and reduce the flow of unwanted fluids, such as water and gas, into the horizontal wellbore and balance production through the interval.

The EquiFlow AICD is Halliburton’s next generation inflow control device (ICD) which utilizes innovative dynamic fluid technology to differentiate between fluids flowing through the device in order to maximize oil production. The AICD works like a passive ICD during oil production, yet restricts the production of water and gas at breakthrough to minimize water and gas cuts dramatically. It uses no moving parts, does not require downhole orientation and utilizes the dynamic properties of the fluid to direct flow.

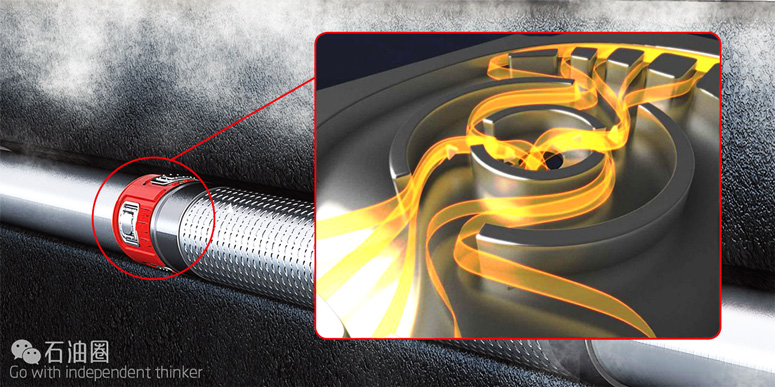

The AICD technology employs an engineered system of flow paths and channels to control fluid flow. More specifically, three individual dynamic fluid components—a viscosity selector, a flowswitch, and a flow restrictor—function together to allow restricted or unrestricted flow of fluid.

The viscosity selector utilizes a system of flow paths which, based on fluid viscosity, density and velocity, “identifies” the fluid(s) that is flowing through the AICD and then divides the total flow among two flow paths. Based off the fluid selector’s output the flow switch, or “fluid crossroad”, directs the majority of the selected fluid down one of two separate paths based on the fluid’s properties. Finally, the fluid restrictor restricts the flow of unwanted fluid (gas and/or water) from entering the wellbore, yet provides very little restriction to the production of the desired fluid.

The EquiFlow AICD is designed to be a simple and cost-effective solution to the limitations of passive inflow control by maximizing reservoir performance, minimizing undesired fluid production, and increasing reliability through design simplicity.

With no moving parts, electronics, and elastomers that can wear out over time, the EquiFlow AICD provides the highest reliability for the life of the well. The tool has undergone and passed rigorous erosion and mud plugging testings.

What Makes an ICD Truly Autonomous?

Simply saying an ICD (inflow control device) is autonomous doesn’t mean it’s true. Putting nozzles in series do not make an ICD autonomous, it must do more. To be autonomous, the flow path inside the tool must actually change. This can be done by moving parts or fluidics, but if the fluid path does not change, then it is NOT autonomous.

Autonomous ICD has the ability to respond to changing well conditions without any action by the operator. When unwanted fluids reach the wellbore, the local autonomous ICD changes the way the fluid is moving inside. This results in a greater restriction to flow while other zones continue production with a low restriction.

Benefits

1.Maximizes ultimate recovery;

2.Increases reliability through design simplicity;

3.Minimizes undesired fluid production;

4.Helps reduce cost and risk associated with unwanted fluid production;

5.Delays onset of unwanted water or gas production.

Features

1.Operates autonomously;

2.Contains no moving parts, electronics, or connections to the surface;

3.Requires no intervention or downhole orientation;

4.Will cease flow restriction if unwanted fluid recedes;

5.Designs available to produce oil and restrict either water or gas;

6.Utilizes innovative dynamic fluid technology to direct flow;

7.Functions as a standard ICD prior to water/gas breakthrough;

8.Each device functions independently for precise response to the reservoir.

Applications

The EquiFlow AICD is designed to improve completion performance and efficiency by delaying the production of unwanted fluids from high productivity zones throughout the length of a completion. Once water/gas breakthrough occurs, the AICD significantly restricts unwanted production, which allows increased oil production from other compartments in the completion. It is installed as part of the completion string and is highly beneficial for any well in which production needs to be balanced over long horizontal reservoirs or in formations with high permeability variances. Typical applications include wells experiencing “heel-toe” effects, breakthrough of water/gas, permeability differences, and water or gas challenges dealing with horizontal or layered reservoirs.

A CASE STUDY: Reducing operator intervention to retard water flow

EquiFlow? autonomous inflow control device helped Repsol recover extra 21,000 barrels of oil, reduced water production 34%, increased oil recovery up to 16%, and had a dramatic return on investment.

In Ecuador, Repsol has a heavy oil field that often produces more than 90 percent water within the first few weeks. To produce more oil, Repsol sought a way to delay water breakthrough. Halliburton began deploying a new generation of autonomous inflow control devices (AICDs) for Repsol in 2012. With no moving parts, the EquiFlow AICD has proven in laboratory flow testing that it can reduce unwanted water by more than 50 percent simply by changing flow behavior. Lighter viscosity fluids take a longer, more tortuous route through the device than oil which takes a short, direct route.

The distribution of EquiFlow AICDs in the wellbore helps balance pressure from toe to heel and compensate for local changes in reservoir permeability. Without the AICDs, water would rise unevenly, breaking through at the most permeable point and stranding reserves elsewhere. The AICDs help delay breakthrough until as much oil as possible has been produced along the length of the wellbore. When water does eventually break through at some point, the AICD changes flow behavior in that zone by creating a greater restriction. This allows more oil to be produced from other zones.

EquiFlow AICDs work as a system, slowing production from high water zones which in turn promotes production from adjacent high oil zones. Post-job production results showed that the EquiFlow AICD helped Repsol recover an extra 21,000 barrels of heavy oil compared to standalone screens in just 300 days.

石油圈

石油圈