近日,Acteon集团旗下的Pulse Structural Monitoring公司推出了第三代INTEGRIpod系统,该设备也成为了INTEGR水下设备监测系统新成员(INTEGRIpod系统是该公司水下监测系统的一部分,对水下设备提供监测服务)。

Pulse Structural Monitoring推出的第三代INTEGRIpod系统具有极高的精确性与稳定性。该设备还具有良好的兼容性,能够与采用标准信息交换技术的不同设备进行数据传递,为水下结构运动监测提供了一双精确的“眼睛”。

INTEGRIpod NXT系统是专门为满足海上石油与天然气开发需求而设计的水下监测设备,为充分发挥行业技术领先优势,该产品采用了标准化和模块化的设计理念。最新型的INTEGRIpod平台系统在保持原有功能的基础上增加了一系列的功能,这些特点使得INTEGRIpo追踪记录功能更可靠、更强大。该系列产品在1998年首次在现场应用至今,已经在深海海底完成了数百万小时的成功作业,这也是对该系列产品功能优异这一特点最好的证明。

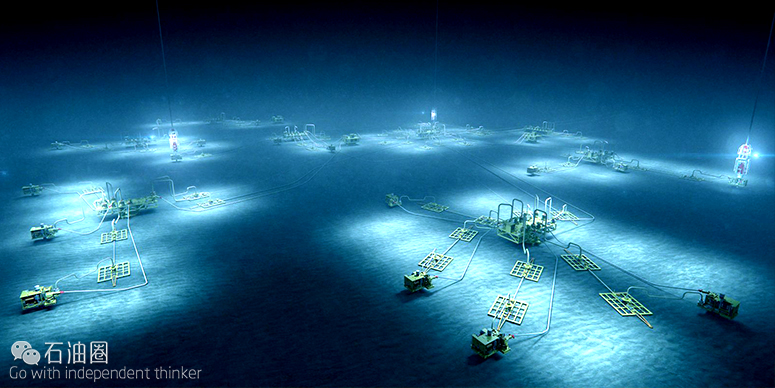

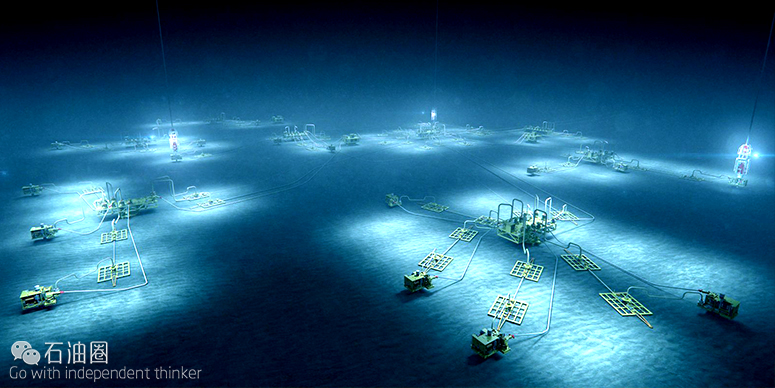

INTEGRIpod水下设备监测系统

INTEGRIpod能够监测和记录水下设备(防喷器组、井口装置、控制系统和锚绳等)的三维加速度、二维角速度和一维倾角等参数。凭借行业内领先的机载处理技术、数据实时处理技术和无线传输技术优势,该系统能够帮助作业人员实现决策的即时性。此设备凭借“智能记录”这一新特点,可以将电池更换周期延长至一年以上,并且“智能记录”可以让设备只在用户设定的值域内对各类参数进行监测和记录,从而显著减少了海上运营成本和海上设备干预调整的耗费。

Pulse技术总监Sandip Ukani说:“新系统的核心部件是一块32位的ARM处理器,它在显著提高机载处理能力的同时,对功耗要求较低,因此电池的使用寿命得到极大的延长。此外,机载MEMS陀螺仪具有极高的精密度和准确性。该平台能够与多种接口种类进行信息交换,包括有线式和声波式,并且与行业内的开发时数据传输标准相兼容,例如RS232/485标准。另外,该系统中数目众多的接口允许其与Pulse其他的传感器兼容、连接、共用。

第三代INTEGRIpod平台系统已经在北海和巴西深海等海况环境极其恶劣的条件下进行了大量的海底试验,取得了非常成功大结果。现在Pulse公司已经将平台系统作为水下结构检测系统的重要组成部分推广,应用在全球多个油田。INTEGRIpod是一款对水下设备运动状态进行监测的数据记录集成设备。

设备部署方式

INTEGRIpod将电子设备、电池和传感器封装在具有抗水压和抗海水腐蚀的密封套管中,可以通过ROV或潜水员在海底管道上进行安装。石油圈原创www.oilsns.com

INTEGRIpod可通过以下方式进行设计,从而实现信息交换:

- 单机系统—将数据保存,在地面进行数据分析,实现设备的离线监测

- 声波传输—采用声波通信技术传输监测数据,实现设备实时监测

- 有线传输—采用控制管缆传输监测数据,实现设备实时监测

系统配置石油圈原创www.oilsns.com

INTEGRIpod的系统配置参数覆盖较宽,能够满足特定的需求,而且还具有数目庞大的标准配置参数可供选择,以满足普通的应用。石油圈原创www.oilsns.com

INTEGRIpod™典型应用包括以下几部分:

- 对隔水管、海底管线和跨接管(涡流与流致振动)振动的进行监测;

- 在安装期间,对水下设备的运动、振动进行监测;

- 对钻井隔水管和SCRs的倾斜角度进行监测、测量;

- 对系泊缆绳运动和张力进行监测。

来自/Pulse Structural Monitoring等 译者/赵金成 编辑/Lemon

Pulse Structural Monitoring, an Acteon company, has launched a third generation INTEGRIpod platform as a new addition to its INTEGRI range of structural monitoring sensor systems.

The INTEGRIpod NXT platform has been specifically developed to meet the needs of the offshore oil and gas industry in the current market; offering industry-leading features in a standard, modular format. Along with a range of new features, the new INTEGRIpod platform will support INTEGRIpod’s impressive track record of reliability and robust performance, proved in millions of hours of successful ultra-deepwater subsea operations since the product range launched in 1998.

Typical applications for the INTEGRIpod range include linear displacement and static and dynamic inclination of subsea structures such as BOPs, wellheads, conductor systems, mooring lines, and jumpers. With industry-leading on-board processing capabilities, measured data is processed in real-time and transmitted wirelessly or hardwired enabling instantaneous operational decision-making. The new platform also allows for deployments in excess of one year between battery change-outs due to new features such as ‘Smart Logging,’ which enables the device to deploy and only record phenomena over client-defined thresholds; significantly reducing campaign costs and the need for offshore interventions.

Sandip Ukani, technical director, Pulse, said, “At the core of the new platform is a 32-bit ARM processor, which offers low power consumption with significant on-board processing capability; delivering best-in-class battery life. The on-board MEMS gyroscopic sensors deliver unrivalled precision and accuracy. The platform allows communication over various connectivity options, including hardwired and acoustic, and can communicate over various industry standard open communication standards, such as RS232/485. Additionally, a multitude of connectors allows direct integration of Pulse’s proven sensor family, including the INTEGRIstick (Curvature Sensor), INTEGRIstrain (Custom Bonded Strain Gauge Packages) in addition to any third party sensor package.”

The third generation INTEGRIpod platform underwent extensive sea trials in the harsh weather of the North Sea, and in deepwater offshore Brazil. It is now ready for deployment as part of Pulse’s extensive fleet of structural monitoring systems.

Pulse Structural Monitoring, an Acteon company, is a leader in marine structural monitoring and has been responsible for providing highly successful monitoring systems and services since 1998.

The INTEGRIpod is a motion sensor with integrated data logger for measuring the movement of subsea structures.

Deployment of loggers

The INTEGRIpod contains all electronics, batteries and sensors enclosed in a pressure rated and corrosion resistant casing. They can be deployed by diver or ROV.

The INTEGRIpod can be set up to communicate in the following ways

- Standalone – to save data on to on-board memory for later retrieval to achieve off-line monitoring

- Acoustic – to transmit data using a through water acoustic link to achieve real-time monitoring

- Hardwired – to transmit data via umbilical to achieve real-time monitoring

System configuration

A wide range of configurations of the INTEGRIpod are available to meet specific requirements. However, there are a number of standard off-shelf configurations optimised to meet common applications.

Typical applications for the INTEGRIpod™ include:

- Vibration monitoring for risers, pipelines and subsea jumpers (VIV and flow-induced vibration)

- Motion monitoring of subsea structures during installation

- Inclination measurement of drilling riser and SCRs

- Motion and tension monitoring of mooring lines

未经允许,不得转载本站任何文章:

-

- Demons

-

石油圈认证作者

- 毕业于中国石油大学(北京),化学工程与技术硕士,长期聚焦国内外石油行业前沿技术装备信息,具有数十万字技术文献翻译经验。如需获取更多技术资料,请联系Demons(QQ2582825239;微信15810965891)

石油圈

石油圈