近日,美国Silica控股公司宣布他们研发出一款新型配方的树脂涂层支撑剂—InnoProp PLT,该支撑剂对于提高低温油层采收率具有非常明显的效果。

通过对聚氨酯配方支撑剂的测试表明, InnoProp PLT支撑剂具有领先的胶结强度、抗压强度和导流能力。InnoProp PLT支撑剂在美国U.S.Silica公司一级运输系统的协助下能运往距离铁路100英里内的作业地点,这些油气井数量超过目前活跃钻井现场的80%以上。

美国U.S.Silica公司油气分公司副总裁和总经理DonWeinheimer说:“目前,石油行业正面临油气价格低迷的挑战,完井工程师为了能够优化油气的产量,正在积极的寻找各种产品提高采收率。参考对外发布的试验数据,从性能角度讲,InnoProp PLT远远比其他低温油层开发所用的涂层支撑剂更好。

在70°F的井底静止低温下,InnoProp PLT在不需要活化剂作用的情况下即可发挥作用,这一特性可以极大降低支撑剂回流量、增大导流能力,实现采收率的提升。此外,InnoProp PLT还具有重复黏合特点,能够在周期性应力下具有非常好的表现。”石油圈原创www.oilsns.com

InnoProp PLT产品具有多种不同尺寸,能够与目前的大多数流体系统相兼容。

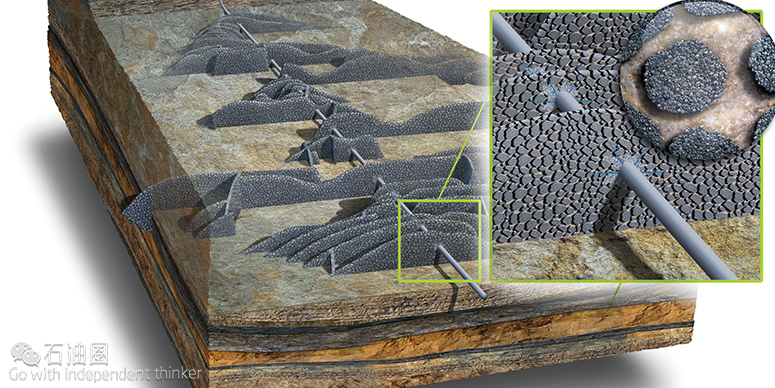

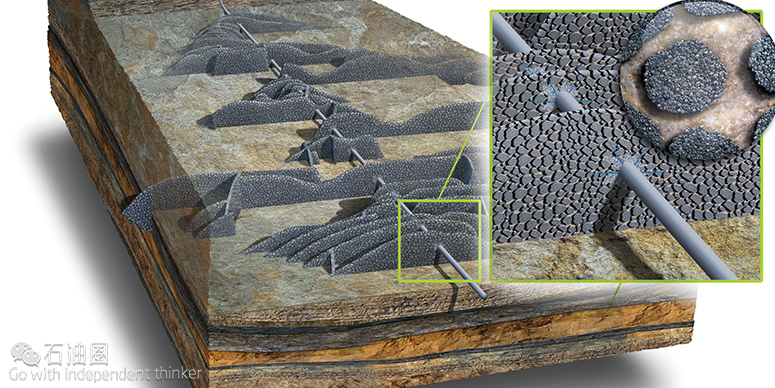

InnoProp PLT 低温涂层支撑剂

InnoProp PLT是一款不含甲醛的树脂涂覆支撑剂,专门为提高低温油层采收率而研发的。该款产品是 U.S. Silica 公司支撑剂产品中的最新产品,能够实现客户提高油气采收率的要求。

该公司研发人员表示:“通过我们公司工程师和研发人员在实验室内的不懈努力,这种基于特殊配方的聚氨酯低温树脂涂层支撑剂具有一流的性能,能够在70°F的井底低温下,可以不采用活化剂就可使用,这是其他同类别产品无法企及的,能够为客户带来巨大的效益。”

特性优势石油圈原创www.oilsns.com

- 一流的胶结强度、抗压强度和导流能力;

- 低温井底储层可以不采用活化剂;

- 极大降低支撑剂回流量;

- 增大导流能力,实现油气采收率的提升;

- 不含甲醛的聚氨酯树脂涂覆支撑剂,无污染

- 重复黏合特点,在周期性应力下具有良好好的表现;

- 在周期应力下,牢固的涂层可降低粉末的产生;

- 产品具有多种不同尺寸;

- 能够与目前所有的流体系统兼容。

针对该服务的前景,该公司表示:“一级铁路运输系统可以根据客户的需求在任何时间将InnoPropPLT支撑剂运往任何地点,我们对当清楚当前的激烈程度,因此我们愿意为客户提供最优质的产品和服务,为了产品能够顺利交与客户,我们客户代表提供全天候的服务。”石油圈原创www.oilsns.com

如需获取关于该技术的更多资料,请联系石油圈技术运营 Demons,QQ:2582825239。

来自/U.S.Silica 译者/赵金成 编辑/Lemon

U.S. Silica Holdings has announced the introduction of InnoProp PLT, a newly formulated resin-coated proppant designed specifically for enhancing the recovery of oil and gas in low-temperature reservoirs.

Independent test results show this proprietary polyurethane-based formula delivers best-in-class bond strength, crush resistance and conductivity. U.S. Silica’s network of transload facilities served by Class I railroads allows InnoProp PLT to be delivered to locations within 100 miles of more than 80% of today’s active drilling rigs.

“With the challenges of today’s oil and gas pricing environment, completion engineers are seeking products that optimize production of hydrocarbons,” said Don Weinheimer, V.P. and general manager of U.S. Silica’s oil and gas division. “According to published test data, InnoProp PLT outperforms all other resin-coated products designed for low-temperature reservoirs, bonding without the use of an activator down to 70°F bottom-hole static temperature. It significantly reduces proppant flowback and provides increased conductivity which enhances hydrocarbon recovery. Furthermore, InnoProp PLT has the ability to re-bond, helping ensure continued performance under cyclic stress.”

InnoProp PLT is available in multiple mesh sizes and is compatible with all current fluid systems.

InnoProp® PLT,Polyurethane Low Temperature Resin-Coated Proppant

InnoProp® PLT is a formaldehyde-free resin-coated proppant designed specifically for low-temperature reservoirs. This new product, the latest in our suite of specialty proppants, reflects our commitment to continually meet customers’ demand for superior products that enhance the recovery of hydrocarbons.

Developed in-house by our team of scientists and engineers, this proprietary polyurethane-based formula delivers best-in-class performance, enabling bonding down to 70°F bottom-hole static temperatures without the use of an activator.

Outperforms Competing Low-Temperature Products*:

- Best-in-class bond strength, crush resistance and conductivity at lower temperatures

- Bonds in low-temperature reservoirs without the use of an activator

- Significantly reduces proppant flowback

- Increased conductivity provides enhanced hydrocarbon recovery

- Formaldehyde-free polyurethane resin coating

- Re-bonding capability helps to ensure continued performance under cyclic stress

- Durable coating reduces fines generation under cyclic stress

- Substrate is U.S. Silica White® sand, ensuring consistent quality in every shipment

- Compatible with all current fluid systems

- Available in multiple mesh sizes

Our broad network of strategically located transload facilities served by Class I railroads enables us to deliver InnoProp PLT where you need it, when you need it. Recognizing that today’s competitive climate requires readily available product and superior customer service, our dedicated customer service representatives are available 24/7 to facilitate smooth delivery of your product.

Compatibility: This resin-coated proppant is fully compatible with most, if not all, commonly used fracturing fluids both water and oil based. Testing with specific fluids prior to pumping is highly recommended. Some fluids may require adjustment of pH control, breaker, or foamer loadings. Avoid prolonged exposure to highly alkaline fluids, i.e. pH greater than 12 and/or greater than the equivalent of 2.2 gallon free caustic soda per 1000 gallons of fluids.

未经允许,不得转载本站任何文章:

-

- Demons

-

石油圈认证作者

- 毕业于中国石油大学(北京),化学工程与技术硕士,长期聚焦国内外石油行业前沿技术装备信息,具有数十万字技术文献翻译经验。如需获取更多技术资料,请联系Demons(QQ2582825239;微信15810965891)

石油圈

石油圈