Emerson is introducing the Roxar FSM Log 48 Area Corrosion Monitor, a new pipeline integrity management system that provides remote, continuous online corrosion and erosion monitoring, enabling operators to track localized corrosion and ensure cost-effective pipeline health even in challenging environments.

The Roxar FSM Log 48 – with 48 referring to the number of pins in the sensing pin matrix – is a large-area, real-time remote pipeline monitoring solution capable of distinguishing between localized and generalized corrosion, a feature that helps reduce the need for pigging and other costlier inspection methods. The Roxar FSM Log 48 has a total cost of ownership of just one typical smart PIG run of up to 10 kilometers (although this can vary according to the PIG technology).

“Localized corrosion, when undetected, can cause pipeline failures that lead to reduced transportation availability and fines or penalties–not to mention repair costs,” said Chuck Miller, Director, Global Midstream at Emerson Automation Solutions. “The Roxar FSM Log 48 reduces these risks while delivering accurate corrosion detection in remote and hard-to-reach places, making it possible to monitor a larger area of pipeline and increasing capacity.”

The Roxar FSM Log 48 continuously monitors corrosion in remote areas using WLAN and cellular data transfer protocols and built-in solar power options that reduce maintenance and personnel requirements. Armed with comprehensive, real-time pipeline health information, operators can make better decisions about when and where to conduct pig runs, integrity digs and hydrostatic pressure tests, which helps to increase pipeline availability and transportation capacity.

The system is specifically designed to work for both uncovered and buried pipelines and is easily installed on bottom pipe sections where water collection is most likely. It can be retrofitted to existing uncovered or buried pipelines and several units can be located over a pipeline, minimizing the need for pigging to assess pipeline integrity and increasing transportation capacity.

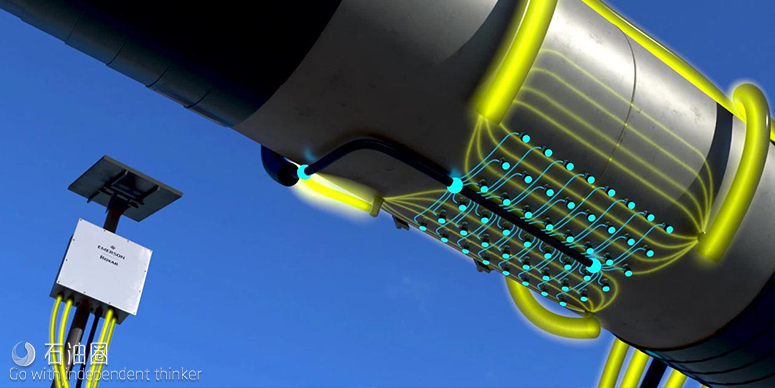

The Roxar FSM Log 48 uses the non-intrusive field signature method, in which an electric current is fed through the monitored length of pipeline to generate an electric field. The initial measurement sequence measures the voltage drop between pairs of sensing pins installed on the external pipe wall. Later measurements are compared to the field signature, where a uniform increase in voltage drops between all pin pairs indicates generalized corrosion, and a local increase in the values indicates localized corrosion. Typical detection sensitivity for generalized corrosion is 0.1 percent of wall thickness for outer pipeline diameters between six and 48 inches.

Roxar FSM Log 48 Area Corrosion Monitor

Corrosion and erosion monitoring solutions are critical to maintaining the integrity of assets and optimizing oil and gas and chemical production. Emerson delivers real time data to enable online plant performance optimization, maximized asset availability and flexibility control and validation of chemical treatment programs, optimization of timing and scope of planned maintenance and early detection of risk on corrosion and erosion events and actual impact – avoiding unplanned outages and leaks.

The Roxar FSM Log 48 Area Corrosion Monitor™ delivers non-intrusive, permanent and cost-effective online area corrosion & erosion monitoring in remote areas. By tracking uniform and localized corrosion and generating online actionable information for pipeline health, the Roxar FSM Log 48 provides operators with increased pipeline capacity, reduced risks of failure, and data-driven pipeline integrity management.

The Roxar FSM Log 48 Area Corrosion Monitor allows you to gain more control over the integrity of your pipeline, maximize transportation capacity and reduce operating expenses. The Roxar non-intrusive area monitoring technology provides unmatched capabilities for detecting general and localized internal corrosion.

Online area corrosion

The Roxar FSM Log 48 Area Corrosion Monitor provides the following benefits:

■ Continuous metal loss trending

■ General and localized corrosion detection capabilities

■ Historic data trending and storage using the Roxar Fieldwatch data management software

Best fit for application

■ Easy to retrofit over any existing pipeline

■ Available for uncovered or buried pipelines from 6″ to 48″ outer diameter

■ Multiple communication options, inlcuding wired, cellular and WiFi

■ Remote power capabilities using solar photovoltaic technology

Measurement principle

The Roxar FSM Log 48 Area Corrosion Monitor feeds current into a pre-defined pipeline section, and through a permanently installed sensing pin array to produce an electric field. Hydrocarbon transportation generates an internal general or localized metal loss, and triggers a change in the monitored area’s electric field.

The Roxar FSM Log 48 Area Corrosion Monitor continuously detects those changes and quantifies the loss of metal in micrometers or mils over each pin-pair, or the total average loss. The Fieldwatch software is used for collecting, storing and evaluating FSM Log 48 Area Corrosion Monitor data.

Specifications

- Temperature (instrument): –40°C — + 60°C (–40°F — 140°F)

- Temperature Sensing Pin Matrix: Low Temp/Buried: –40°C — +130°C (–40°F — 266°F)

- Ex Classification: Ex Certified Version: II 2G Ex e ia mb IIC Gb -40°C < T < +60°C (–40°F — 140°F)

- Communication: Wired — Roxar proprietary Fieldbus SystemWireless: GSM and Wi-Fi

- Number of sensing pins: 48 pins

- Pipeline Outer Diameter 6 inches to 48 inches

- Pipeline Type Uncovered and buried

石油圈

石油圈