Founded in 2014, Fracture ID offers a new service called “drill bit geomechanics” that could become an early warning system for frac hits caused by pressure and hydrocarbon depletion from older producing wells.

The wellbore-focused service has been used by more than three dozen operators to improve on several different aspects of completion efficiency, including helping to make sure proppant effectively moves into perforations.

While a lot of its work is focused on what is happening around the wellbore, over the course of its 350-well track record the company has determined, “what we’re measuring in the near-field has some extension out into the far-field,” said Chris Neale, the chief executive officer and founder of Fracture ID

He explained that the downhole data the firm gathers during drilling show correlations to the pressures that operators monitor during and after stimulating a fracture stage. This relationship is seen as one key to predicting which stages will most likely lead to fracture interference.

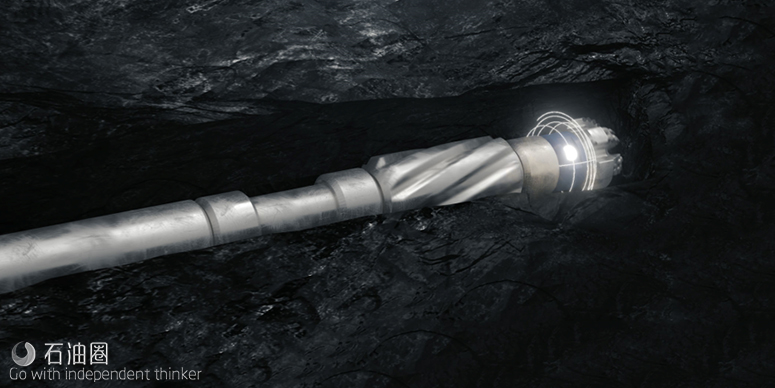

At the core of Fracture ID’s service is a foot-long accelerometer device that sits behind a drill bit and enables the Denver-based firm to translate drilling vibrations into critical rock descriptions, including stress and strain, two performance-driving factors for completions.

In areas of the lateral where the device detects unusually low stress and brittle rock, there is a correlating signal seen in the post-fracture treatment pressures, which Fracture ID interprets as an indication of depletion within the reservoir.

Conversely, a stage under higher stress has far less pressure pushing back, a sign that a smaller wedge of rock was opened. The takeaway here is that these stages have more pressure containment around them, and are less prone to inter-well communication effects.

It’s a “Spaghetti Monster”

These relationships cannot be established in a single well. But after a few are drilled and completed, and pressure communication events are studied, Fracture ID says shale explorers will have an idea of where the most depleted zones probably are.

“And if you know the geology, then you should complete the well differently—the same way you should walk down a hallway differently” once the lights are on and you can see all the obstacles in your way, said Josh Ulla, vice president of business development of Fracture ID.

A former borehole seismic expert with ExxonMobil, he noted that due to the high cost of traditional well logs, many producers only obtain downhole rock measurements on pilot wells. The price of not having more of that data comes in the form of vague models that frame depletion as uniform ellipses around wellbores.

“But the first thing you see when you start studying depletion is that it looks more like a spaghetti monster—it’s going off in all angles and is asymmetrical,” Ulla said, adding that despite their inaccuracy, operators remain reliant on these models to help determine well spacing.

Fracture ID thinks that because the cost of its service is a fraction of traditional well logging, it justifies the data acquisition effort needed to enhance the depletion models. It recently launched a 10-well study with two clients to prove it.

The startup says its approach has already seen some validation. Last year, its technology was used in a science project with shale producer Liberty Resources. A new well was drilled perpendicular to and under three vintage wells in the Bakken Shale, only two of which had ever been hydraulically fractured. According to a jointly authored case study, “indications of depletion and induced mechanical heterogeneity were observed only adjacent to those stimulated wells.”

Fracture ID is recognized as an industry leader in the rapidly advancing field of Drillbit Geomechanics™

- A 3 component (3C), high frequency accelerometer is deployed in the BHA while drilling

- Each cutter head on the PDC bit deforms the rock in a manner comparable to an earthquake

- Earthquake seismology is applied to convert 3C accelerations into 3C Stress/Strain

- These Stress/Strain Relations provide high resolution, in situ rock properties along the well:

- Young’s Modulus

- Bedding Presence

- Poisson’s Ratio

- Fracture Intensity

Core Comparison

Coring is a fantastic opportunity to recover the actual reservoir rock to the surface for analysis. Some business impacting core measurements include porosity & permeability. Collecting Drillbit Geomechanics while coring allows for in situ rock mechanical measurements to be recorded so that these high value core measurements can be better mapped onto future vertical & lateral wells. In this example Fracture ID’s measurements are overlain on the core pictures. They show tracking of the lithological make up & showcase Drillbit Geomechanics™ high resolution capabilities

Sonic Dipole Comparison

Below is an example from the Midland Basin where both FID (black) and dipole sonic (blue) data were collected. The left is the entire well, while the middle is a zoomed in section (Lower Sprayberry) and the right is that same section with a 4 ft smoothing filter applied. As the sonic tool surveys a larger section of rock the smoothed Fracture ID results compare best when smoothed to its resolution. But keep in mind that the Fracture ID results have more information available at native resolution.

Image Log Comparison

Image logs are some of the highest resolution tools available and using the actual mechanicals along the well to better interpret these logs is very powerful. In this example the Young’s modulus is overlain. This helps to discern the lithologies that make up the different rock types being intercepted by the well.

石油圈

石油圈