Coatings formulated with LUMIFLON FEVE resins from AGC Chemicals Americas are ideal for offshore and marine structures like oil rigs, tanks and vessels because they provide excellent corrosion protection and guard against ultraviolet rays, wind, rain, chemicals, dirt and petroleum products, according to a company press release. LUMIFLON-based coatings can be formulated to last for 30 to 60 years. These resins are designed to reduce life-cycle coating costs, improve asset utilization and eliminate the need for multiple painting cycles.

LUMIFLON is the first solvent-soluble fluoropolymer resin for coatings that can be cured at room temperature or at elevated temperatures. LUMIFLON resins, used in topcoats, are ultra-weatherable, and maintain their excellent appearance on buildings, bridges, and other structures, as well as on aircraft, automobiles, and solar panels. LUMIFLON coatings protect steel, aluminum and other metals as well as concrete from degradation by UV light, wind and rain, and corrosion. A transparent fluororesin, LUMIFLON can be used to make both clear and pigmented coatings. Because of their ultra-weatherability, LUMIFLON based coatings offer substantial life cycle cost savings over conventional coatings. The resins can be formulated into coatings with a range of gloss (from high gloss to flat finishes) in more than 230 colors. LUMIFLON resins are available for almost any type of coating, including solvent based resins, powder coating resins, environmentally friendly solid resins for low VOC and HAPS free coatings, and water emulsion and water dispersion resins.

LUMIFLON is one of many quality products made by AGC – Asahi Glass Company – established in Japan in 1907. In just over a century, AGC has gone from a small glass company to a diversified, multibillion- dollar enterprise. AGC first developed its solvent-soluble LUMIFLON fluoropolymer in 1982 — and it didn’t take long for manufacturers to discover that this resin was different. LUMIFLON resins allow coatings to be cured at room temperature. For the first time, the durability, weatherability and long-term cost effectiveness of fluoropolymer coatings were now available for field application. With their superior performance and life cycle cost advantages, it’s no wonder fluororesin paints based on LUMIFLON have since been produced by many manufacturers and applied to more than 150,000 industrial and architectural structures, aircraft and automobiles worldwide.

LUMIFLON is just one of the many innovative products and materials created by AGC, a company that’s driven to excel in a high-tech world. But what a difference it makes for manufacturers and builders who demand the combination of quality and value that only LUMIFLON delivers.

LUMIFLON is known generically as an FEVE resin. Its unique alternating structure is key to its ultra-weatherability.

Advantage

1.aesthetics: LUMIFLON-based coatings offer brilliant, long-lasting colors with a wide gloss range. They simply look great – and keep looking great year after year.

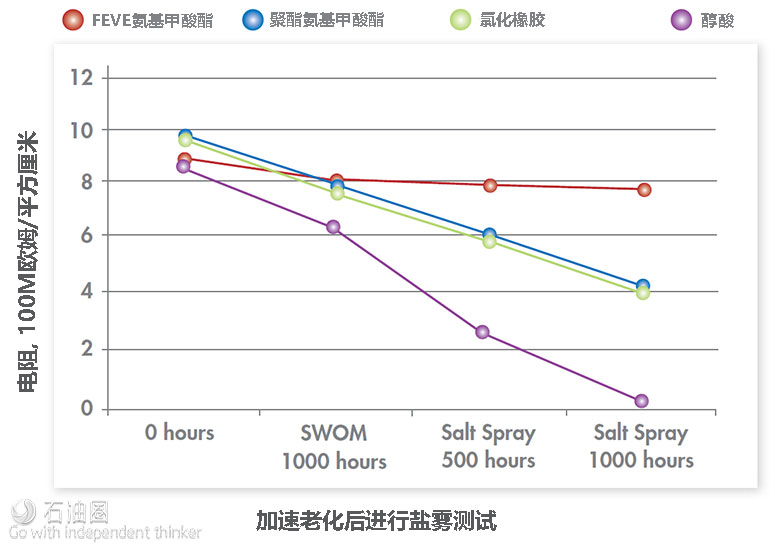

2.corrosion prevention: LUMIFLON’s unique chemical structure improves resistance to corrosion from water, oxygen and even chloride ions, ensuring a longer life for industrial structures like bridges with far less need for repainting.

3.sustainability: With its long lifespan, LUMIFLON eliminates the environmental impact of repeated repainting and recoating – just one of the reasons LUMIFLON coatings can contribute to LEED certification.

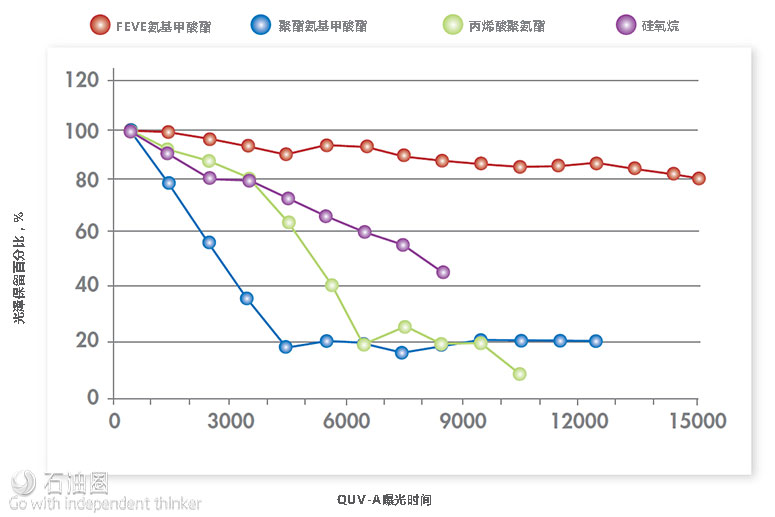

4.outperforms the competition: No other coating type can match LUMIFLON’s combination of attractiveness, application flexibility and – as tests and studies confirm – long life and weathering resistance.

5.lower life cycle cost: Because they last so much longer, LUMIFLON-based coatings can substantially reduce any project’s life space cycle costs, including maintenance costs, replacement costs and recoating costs.

Aesthetics

Because LUMIFLON-based coatings offer crisp, clean colors and a wide range of gloss, designers and builders choose them to achieve a superior look from day one. And with LUMIFLON’s ability to resist UV degradation, corrosion, and the ill effects of chemical exposure, projects using LUMIFLON continue looking good for years to come with little or no maintenance required. That means markedly less fading, discoloration and chalking for the life of the coating – estimated at up to 60 years! Meanwhile, AGC’s research and development team continues to press LUMIFLON’s aesthetic advantage with new FEVE resin formulations that add even more improvements, like the ability to resist dirt and grime.

Corrosion Resistance

Corrosion is a major problem that can dramatically add to a project’s life cycle costs, especially for bridges, water towers and other metal structures.

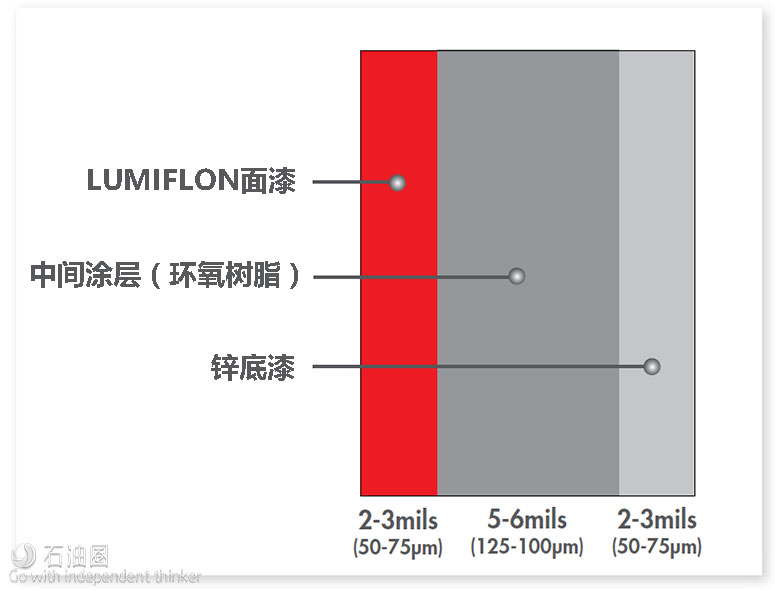

A LUMIFLON-based coating

Resists degradation due to weathering and exposure to chemicals

Over the course of many years, loses little of its thickness

Keeps corrosion initiators from penetrating the topcoat and degrading the zinc-rich primer underneath

Has an estimated coating life of 60 years or more

Corrosion resistance is directly related to the slope of the line. The lower the angle difference from horizontal, the better the corrosion resistance.

Sustainability

The weatherability, longevity and the ability to formulate low VOC coatings with LUMIFLON resins are all features that contribute to its sustainability, a concept meaning: “to reduce consumption of non-renewable resources, minimize waste, and create healthy, productive environments”

“Reduce consumption of non-renewable resources”

LUMIFLON coatings can last up to 30 years without fading, reducing life cycle costs related to the maintenance, re-application and/or replacement of underlying surfaces. On existing roofs, a LUMIFLON topcoat can stop the degradation of the underlying reflective coating, thus extending the life and solar reflectance capability of the roof and minimizing the use of raw materials derived from oil.

“Minimize waste”

By extending the life of roof and wall systems, LUMIFLON topcoats reduce waste created from disposal of damaged roofing and walls; avoid energy consumption in the production, transportation and installation of new systems; and maintain energy and equipment savings from continued high-performance of the building envelope. In addition, the energy consumed in removing a coating from a building or structure can be avoided through the use of a new paint product containing a LUMIFLON clearcoat with excellent durability and weatherability.

“Create healthy, productive environments”

There are four types of LUMIFLON resins, three of which – solid, powder, and emulsion grades contain either zero volatile organic compounds (VOCs) or can be formulated to contain less than 50 g/L of VOCs, meeting the most stringent green building criteria in the US. Due to its longevity, LUMIFLON reduces the environmental impact associated with production, transportation (energy consumed, greenhouse gases emitted), and VOCs off-gassed during the repainting/recoating process.

Outperforms the Competition

Industry insiders know that, from buildings and bridges to water towers and automobiles, LUMIFLON-based coatings look great. But they look even better when cold, hard data comparing LUMIFLON with high-performance polyesters and other competitors are collected from tests and studies conducted in laboratories, simulators and harsh, real-world environments.

Advantages of FEVE Based Coatings

Ambient or elevated temperature cure – field or shop applied coatings

Solvent soluble – clean crisp colors and a wide gloss range

Versatile – solvent grade, solid, water based and powder coating resins offered

OH functional – polyurethane chemistry, use standard paint equipment

Fluoropolymer segments – ultra-weatherable and corrosion resistant

Longer life cycle – up to 60 years

Lower life cyclecost

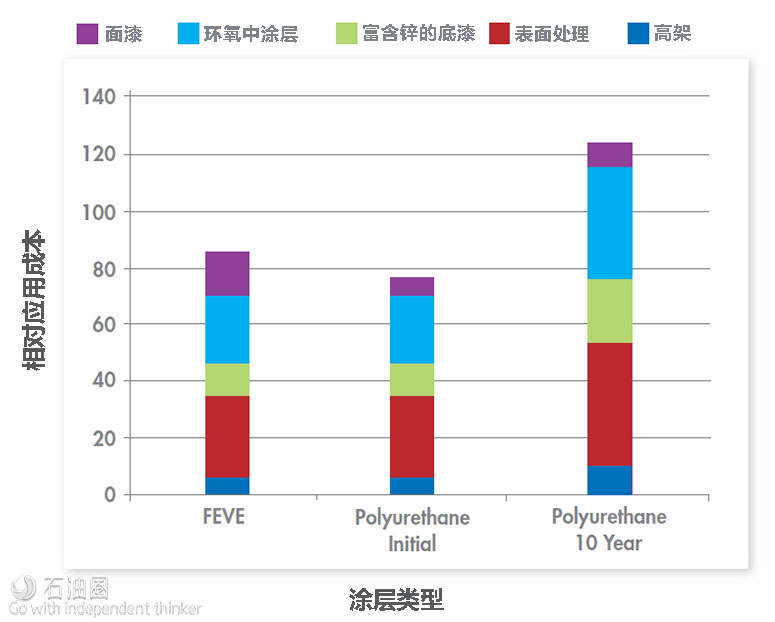

There are those who make buying decisions based on price – and then there are those who are more interested in value. With LUMIFLON, the difference is clear.

LUMIFLON-based coatings maintain gloss and color when applied to buildings, bridges, water towers, and other structures for between 20 and 60 years – significantly longer than other coating types.

LUMIFLON resins protect steel, aluminum, fiberglass, concrete, and other materials from corrosion, sun, wind, rain and chemical exposure.

Over time, all that protection also protects your bottom line. Total life cycle costs, factoring in savings on maintenance, recoating and replacement, are much lower with LUMIFLON. Based on results from numerous projects, it’s estimated that the life cycle cost of LUMIFLON coatings is only 40-80% of that of polyurethane. Price versus value. Over the course of a project’s lifetime, the difference can be monumental.

Life Cycle Cost Advantages

Initial applied cost of FEVE-based topcoat: 5-10% higher than standard polyurethane topcoat

FEVE-based topcoat life expectation: 30-60+ years

Expected maintenance of standard polyurethane topcoat in this time frame: 2-3 repainting cycles

Additional costs of repainting:

–Asset downtime

–Staging costs

–Environmental costs

–Emissions and CO2 from equipment

石油圈

石油圈