This paper presents the results of reservoir simulations for the Mauddud reservoir in the Sabiriyah field (SAMA) in Kuwait, which is a high temperature and high-salinity carbonate reservoir. The subject reservoir has been under pattern waterflood. Many wells experienced water breakthrough with considerable increase in water cut because of high reservoir heterogeneity and adverse mobility ratio. This study provides technical analysis of the viability of enhanced-oil recovery (EOR) processes; the results indicate the potential for significant improvement in recovery efficiency over continued waterflooding.

Introduction

SAMA is a giant carbonate oil reservoir covering more than 200 km 2 in northern Kuwait. Oil production began in January 1958 and continued under primary recovery until 2000. In 1998, a waterflood pilot was conducted successfully. As a result, inverted-nine-spot waterflood patterns were implemented in 2001. As of 2011, the fieldwide water cut reached approximately 30%.

Sector Model

A large sector model was developed to study field-scale fluid-flow behavior in SAMA. The first step in generating a sector model was to identify an area of interest (AOI) suitable for EOR applications. A sector geocellular model was then developed for the selected AOI with available petrophysical and geological data. A sector simulation model was obtained from the upscaling of the sector geo cellular model. The sector simulation model was calibrated with the production, pressure, and other surveillance data from the wells in the sector-model area. The history-matched model was then used to perform gas-EOR-forecast simulations.

Chemical-EOR Laboratory Experiments

Chemical-Fomulation Selection. A chemical formulation consisting of C28 –25PO-45EO-carboxylate as the primary surfactant and a mixture of C15–18-IOS and C 19–28 -IOS cosurfactants was selected. No cosolvent was required. Tetrasodium ethylene diaminete traacetic acid (EDTA) was used to chelate ferric ions because the reservoir core was found to contain ankerite. EDTA also tends to convert an oil-wet rock to waterwet, an added benefit because the SAMA reservoir rock is oil-wet.

Microemulsion Phase-Behavior and Coreflood Test.

The laboratory solubilization-ratio data were matched by use of the phase-behavior model in a widely used simulator to obtain the input parameters for pilot simulations. The optimum solubilization ratio shows a value of approximately 12.5. The corresponding interfacial tension (IFT) is approximately 0.002 dynes/cm, which is approximately four orders of magnitude lower than the water/oil IFT with no surfactant present.

The initial coreflood results on outcrop cores showed excellent performance of the surfactant/polymer (SP) process. FP 3330S polymer was used for mobility control. Subsequently, the SAMA reservoir cores were used in the coreflood experiments. A final recovery of 91% of the waterflood residual oil was achieved from this SP coreflood experiment. The high recovery factor demonstrates the efficacy of the chemicals selected.

The most meaningful oil-recovery metric is the final oil saturation after SP injection (Sorc ). The Sorc in the SAMA composite SP coreflood experiment was approximately 0.03, a very low and favorable value that indicates a very effective chemical formulation.

Salinity Gradient. The salinity gradient during the SP coreflood is one of the most important design variables that determine chemical-flood performance. In general, the salinity of the SP slug should be lower than the formation-brine salinity and the salinity of the polymer drive should be lower than the salinity of the SP slug.

The core was flooded with synthetic hard produced brine with a salinity of 101,000 ppm total dissolved solids (TDS). The salinity of the injected SP slug was 73,000 ppm TDS, which is the optimum salinity of this chemical formulation. The polymer solution was then injected at a lower salinity of 41,000 ppm TDS, to provide a negative salinity gradient and a final salinity in the Type I phase-behavior environment.

EOR Pilot-Scale Model

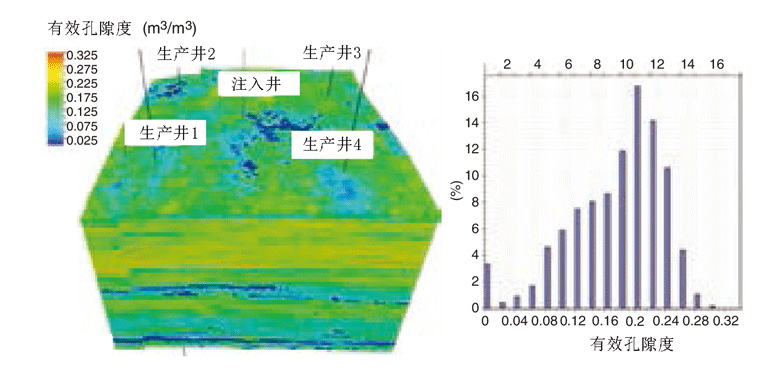

Fine-Grid Pilot-Scale Model.A fine-grid model with an areal cell size of 5×5 m was designed for the pilot-scale model area. The number of cells in the fine grid simulation model is 3,996,400. A vertical grid resolution of approximately 0.75 m was used, which resulted in a total of 100 layers. Fig. 1 illustrates porosity distribution and a histogram from the fine-grid simulation model. The inverted- five-spot pattern was the pattern used for the waterflood pilot conducted in 1998. The pilot-scale model is inside the waterflood-pilot area. Acceptable representation of the waterflood-pilot data using the fine-grid simulation model helped validate the model construction and provide fluid-saturation distributions in the pilot-scale model area.

Once the history match of the waterflood pilot using the fine-grid simulation model was completed with the Sorw value of 31.5%, an EOR pilot-scale simulation model for performing chemical- and gas-EOR simulations was extracted from the history-matched fine-grid simulation model.

Pre-EOR-Waterflood Simulation. A pre-EOR waterflood simulation was performed before the chemical or gas injection to condition the pilot area. A total volume of water corresponding to 0.225 pore volumes (PVs) was injected for a period of 90 days. The results indicate that the injected water has reached the producer after 90 days of water injection. The pre-EOR-waterflood recovery was estimated to be approximately 9.7%.

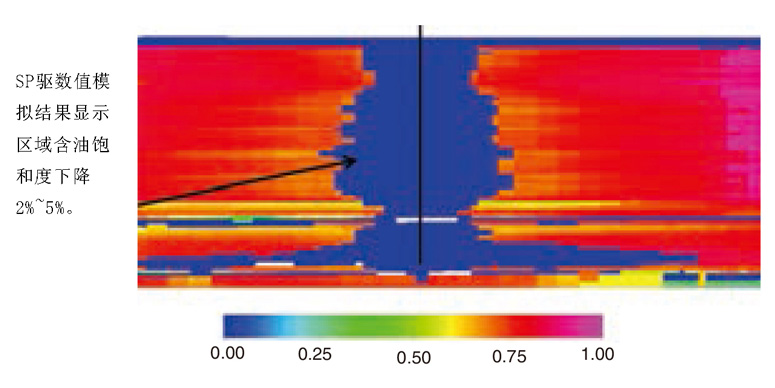

SP Simulation.A 0.3-PV SP slug containing 1.5 wt% surfactants and 3,500 ppm polymer was injected after the pre-EOR waterflood. The SP slug was injected at an injection rate of 5,800 B/D. Fig. 2shows a cross-sectional view of oil saturation after 19 days or 0.05 PV of SP-slug injection. The surfactant reduced the oil saturation in the flooded zone to low values between 2 and 5%. Use of polymer in the SP slug improved the overall sweep. The SP slug was followed with the polymer drive, with a polymer concentration of 3,500 ppm. The chemical SP process was estimated to increase oil production significantly. The total oil recovery for the SP process was 60%, compared with 35% for the waterflood. Thus, an incremental oil recovery of 25% over the waterflood was achieved with the SP process.

Continuous-Gasflood Simulation. Carbon dioxide (CO2 ) was chosen for gas- injection processes for the SAMA EOR pilot-scale simulations. The laboratory data indicate that the residual oil saturation to immiscible gas is approximately 25%. The effect of IFT on residual oil saturation and oil relative permeability was considered in the gas-EOR-process simulations.

During the simulations, CO2 injection was started after the pre-EOR waterflood. The injector was given a maximum-bottomhole-pressure (BHP) limit of 3,700 psia. An incremental oil recovery of approximately 13% over waterflood was estimated after 581 days of CO2 injection. The CO2 injection was estimated to reduce oil saturation of the reservoir that is in contact with the injected CO 2 . Because of reservoir heterogeneity and poor mobility control, the vertical sweep of the CO2 flood appears to be inferior to that of the chemical SP flood.

The WAG-injection scheme injected CO2 for 1.5 months followed with 1.5 months of water injection. After six cycles of WAG injection, oil recovery of 37.3% was estimated from the pilot-scale simulation model. Including the 9.7% of oil recovery estimated from the pre-EOR waterflood, the overall oil recovery was estimated to be approximately 47%.

The total volume of CO 2 injected was estimated to be 1.54×10 9 cf, which is less than 50% of the volume estimated for the continuous CO 2 flood. An improvement in oil recovery of approximately 9% was estimated for CO2 WAG injection compared with the continuous CO2 flood. The reason was the improvement in mobility during WAG injection.

Summary of EOR Pilot Simulations. Five processes were simulated with the pilot-scale simulation model: waterflood, polymer flood, continuous CO 2 flood, CO 2 WAG injection, and chemical SP flood. The results indicate that the chemical SP flood performs the best in terms of the estimated oil- recovery factor. The CO 2 WAG process performs better than the continuous CO 2 flood, and the waterflood was estimated to perform poorly, with an oil- recovery factor of approximately 25%. The polymer flood was estimated to yield an additional oil recovery of approximately 17% over waterflood.

The results suggest that heterogeneity in the SAMA reservoir is one of the key factors affecting oil recovery. To realize high oil recovery from the SAMA reservoir, displacement processes including injection-fluid mobility control are recommended. The EOR pilot-scale simulation results suggest that both CO 2 WAG and chemical SP processes could improve oil recovery from the SAMA reservoir significantly.

石油圈

石油圈