As deepwater Gulf of Mexico (GoM) fields enter maturity, the need for intervention and workover operations becomes more frequent. The nature of these operations also is highly complex due to the inherently complicated installed completions. To combat these growing challenges, nontraditional tools and methods must be employed. This was recently the case during a workover campaign at BP’s deepwater Atlantis Field where nontraditional deepwater technology was successfully implemented to solve a complex wellbore challenge.

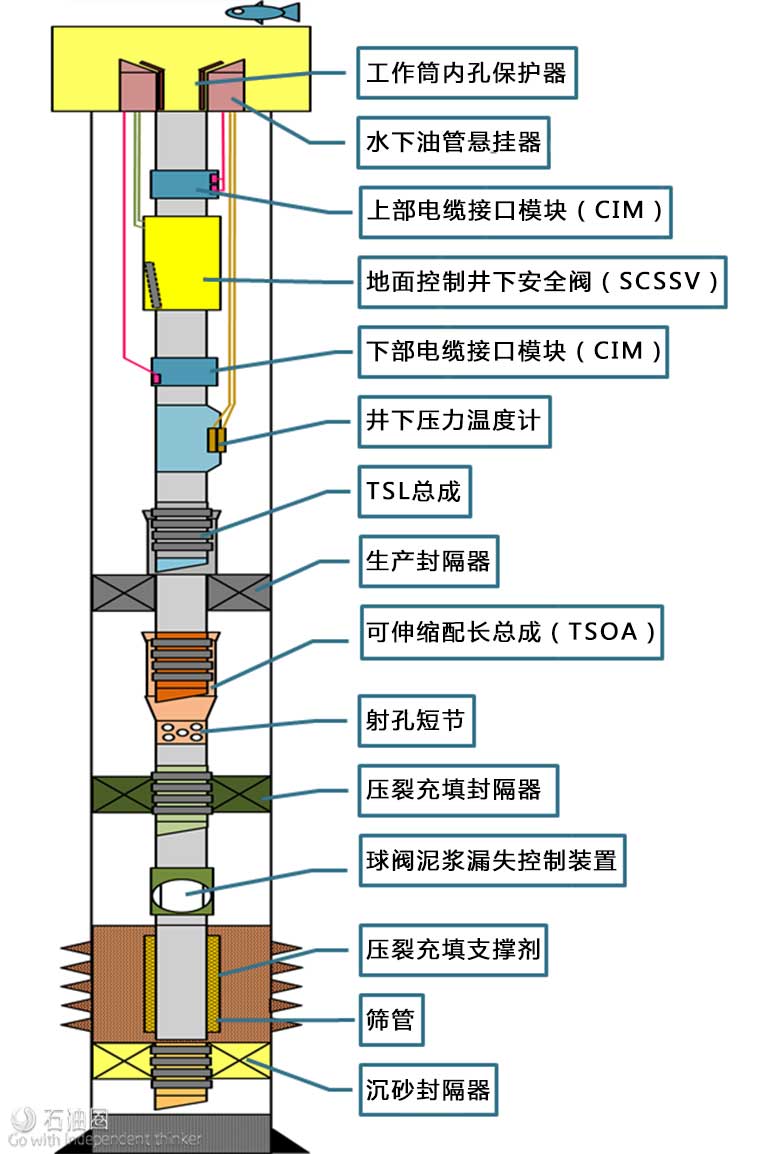

The Atlantis Field is located in the deepwater GoM approximately 241 km (150 miles) south of New Orleans in more than 2,133 m (7,000 ft) of water. The main targets are Miocene reservoirs ranging from 4,876 m to 5,486 m (16,000 ft to 18,000 ft) true vertical depth. Early completion designs utilized a monobore concept; this involved the removal of flow restrictions along the inside diameter (ID) of the tubing string to promote better productivity. Therefore, nipple profiles were avoided, including the typical nipple profile placed below the production packer for intervention purposes.

Two of these monobore completions required their upper completion strings to be replaced during a workover/intervention campaign. The reservoir of each well needed to be mechanically isolated prior to removal of the upper completion string. However, without a nipple profile beneath the production packer, the conventional method of setting a lock and plug beneath the production packer was not an option.

Selection mechanical bridge plugs

Before the reservoir could be isolated, the surface-controlled subsurface safety valve (SCSSV) had to be locked open using an insert sleeve device to facilitate intervention operations deeper in the wellbore. The insert sleeve created a mechanical restriction in the well. Therefore, a mechanical isolation device was required to pass through the ID restriction of this insert sleeve and then be set in the ID of the tubing beneath the production packer. This requirement limited the technology selection to mechanical bridge plugs with high-expansion ratios (i.e., devices with a small running outer diameter (OD) but with the ability to expand to set large ID tubing).

The mechanical bridge plug technology selected was a retrievable inflatable bridge plug (RIBP), given that it was the only available product that met the requirements for the intervention operation:

Maximum OD small enough to pass through a 4-in. ID restriction;

Ability to be set in a 4.67-in. ID;

Conveyable on wireline;

Minimum differential pressure rating of 5,000 psi at 71 C (160 F);

Ability to hold pressure in both the positive and negative directions;

Retrievable via either slickline or wireline; and

Retrievable through a 3.688-in. restriction.

The application of inflatable technology to deepwater subsea interventions was not common to the Atlantis project. Historical success statistics with the planned RIBP were examined to gain confidence in its planned application. The statistics examined were focused on the particular size of RIBP planned for use, and analysis of the statistics demonstrated there was a high probability of success regarding use of the RIBP.

Well intervention

The intervention procedure for the two wells involved a series of steps that included drift runs, locking open the SCSSV, setting of the RIBP, removing the upper completion equipment, rerunning of new upper completion equipment, cleaning above the RIBP, retrieving the RIBP and confirming integrity of the newly installed upper completion. However, the focus was placed on operations regarding the RIBP.

The wireline conveyance of the RIBP to the target setting depth was performed using a subsea landing string from surface to the subsea tubing hanger. The subsea landing string was filled with base oil during this operation and the completion tubing was filled with wellbore fluids. As a result of these fluids, the RIBP installation operation was performed on a live well.

Once the RIBP was correlated on depth and set in place, it was pressure tested to 8,000 psi above surface pressure at the pressure-controlled equipment. After the positive pressure test, the applied test pressure was bled off to leave the original surface pressure on the well. The pressure was then bled off on surface, thereby subjecting the RIBP to a negative pressure test load. Both the positive and negative pressure tests were successful, verifying the integrity of the RIBP. This was critical given that it would be exposed to several different pressure loads during the intervention scope of work.

In addition to the loads encountered during the course of the intervention, one of the two wells that employed the RIBP for reservoir isolation during the intervention campaign had to be temporarily suspended due to adverse weather conditions. To achieve this suspension, the deepset RIBP was pressure tested, allowing it to perform the task of a mechanical well barrier for 36 days.

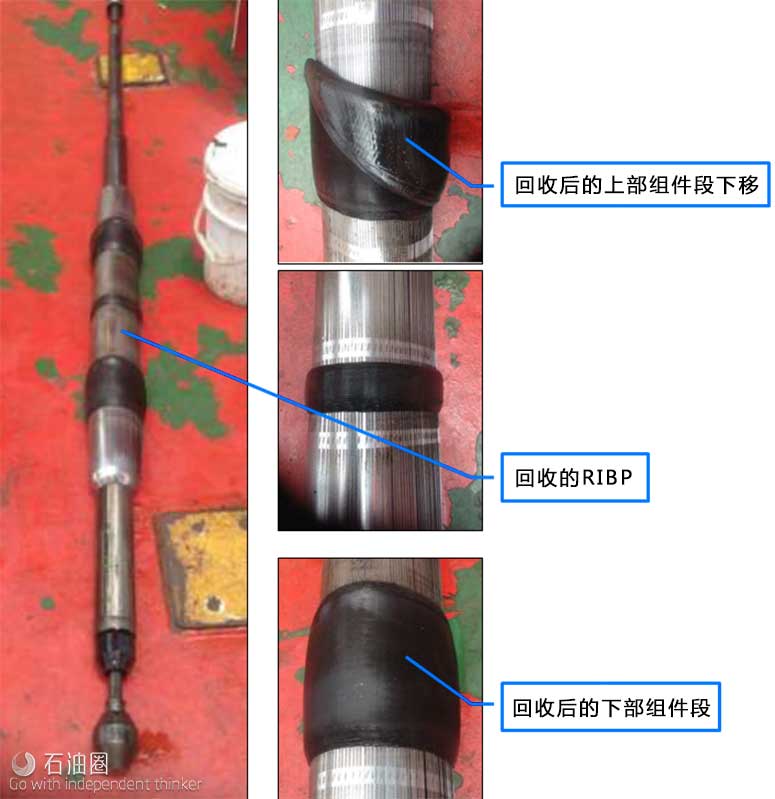

Once the upper completion equipment was successfully retrieved and new equipment installed, the RIBP was recovered from the well. The entire RIBP assembly was retrieved with no components missing. However, on the first RIBP application, the upper element of the RIBP assembly was rolled off slightly. This was attributed to pulling the RIBP through the 3.688-in. nipple profile, which represented the smallest restriction through the new upper completion string.

Lessons learned

This high-expansion ratio RIBP was found to function successfully under a diverse range of conditions.

The plug successfully isolated the reservoir during the intervention scope of work, despite the varying pressure and temperature loads to which it was subjected. It served as a thru-tubing mechanical plug for the functioning and testing of the SCSSV, production packer and production tubing after installation of the new completion tubing. The RIBP also served as part of the mechanical barrier required for temporary suspension on one of the two wells during the intervention campaign and was successfully retrieved through a 3.688-in. nipple profile restriction after being installed in the wellbore for several weeks.

The RIBP performed several functions and the resulting performance on both subsea well interventions was found to be satisfactory. The overall utilization times of the RIBPs (from setting to retrieving) were 22 days on the first intervention and 64 days on the second.

While the overall use of the RIBP for reservoir isolation during the intervention campaign was successful, minor lessons were learned during the operational execution:

1.Debris management above the deep-set RIBP is critical to the retrieval operation. Prevention of debris deposition as well as properly planned cleaning operations using effective cleaning technology is critical to the success of the retrieval operation; and

2.Sufficient time should be allowed for the defl ation of the infl atable element during the unsetting and retrieval operation.

Retrievable bridge plugs with high-expansion ratios and high differential pressure ratings are not very common in the deepwater industry. Interest in their use is becoming more prevalent due to the demands of deepwater subsea intervention activities. This environment demands reliable technology with high-performance features and functions. The successful application of the RIBP presented offers the intervention community supporting information/evidence and a case study for the future use of this technology.

石油圈

石油圈