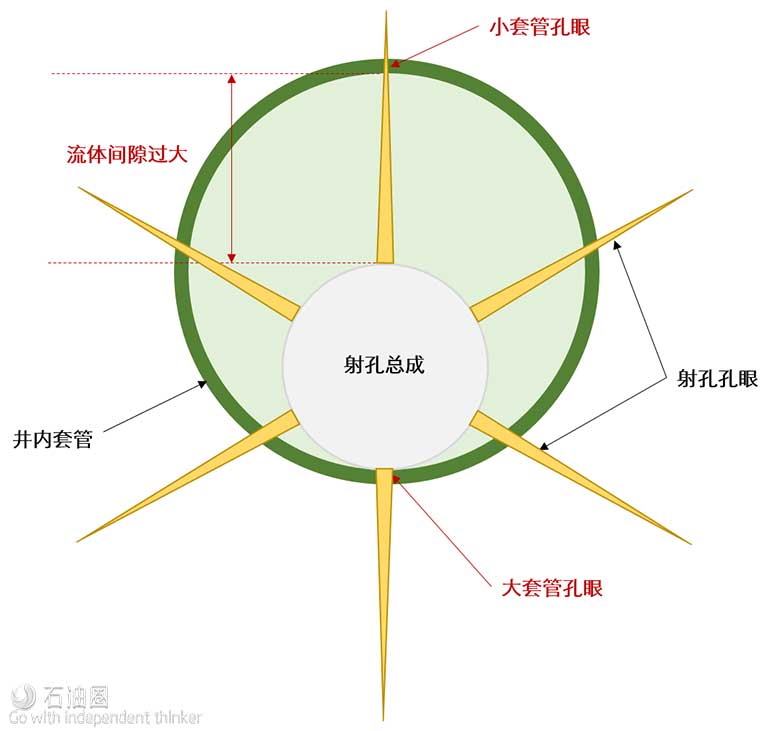

Perforating in a decentralized and deviated well, an operator has to account for the inconsistent Entry Hole (EH) size caused by the fluid filled annular space between the perforating gun’s outer wall and the target casing’s inner wall. This area is often referred to as the ‘fluid gap’ and has caused operators to misunderstand the total flow area generated by the perforating shot density. Hunting’s EQUAfrac Shaped Charge is designed to reduce variation in EH diameter for decentralized well completions to optimize well production rates.

Conventional Shaped Charge Technology

Conventional Deep Penetrating (DP), Super Deep Penetrating (SDP) and Good Hole (GH) shaped charges are unable to overcome the fluid gap and provide an inconsistent hole in a decentralized environment.

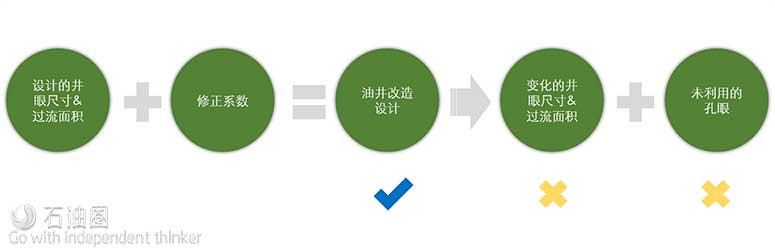

Because of the inability to produce a consistent hole size, operators that use these charge types in decentralized settings must adjust calculations to allow for maximum and minimum clearance. Non-uniform EH diameter leads to issues such as erosion and slotting of small perforations, under-utilization of all perforations, less efficient well stimulation, and slow ramp-up to intended treating pressures.

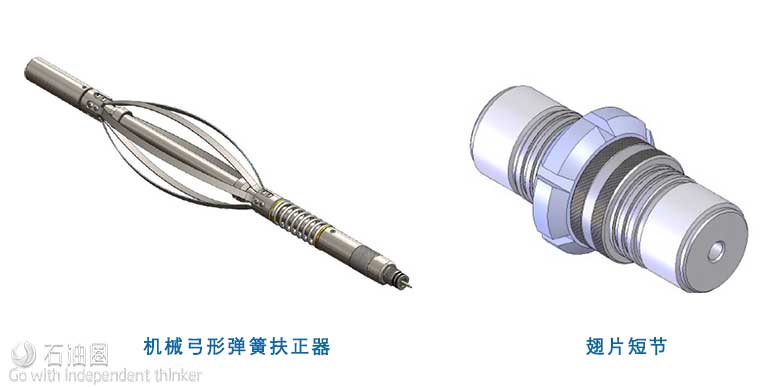

To overcome these problems engineers have used hardware to centralize a perforating gun string in the wellbore. Traditionally, mechanical bow spring centralizers or fin subs have been used as a means to centralize a perforating gun string.

Mechanical Bow Spring Centralizer: When perforating with small diameter tubing guns a bow spring centralizer may be added to the perforating gun string. A bow spring centralizer can increase the length of a perforating gun string by thirty inches and weight by twelve pounds. In many cases multiple bow spring centralizers are used further increasing overall length and weight of a perforating gun string.

Centralizing with Finned Subs and Rings: When perforating with larger diameter expendable perforating guns a finned sub or a ring may be used to centralize the gun string. A finned sub features a collar that is welded onto a tandem sub. A ring is placed over a perforating gun and welded into place. Multiple finned subs or rings may be used adding to the weight of a perforating gun string.

Any type of centralizing hardware adds to the outside diameter of a perforating gun string potentially limiting access to some wellbore depths due to diameter restrictions.

Consistent Hole Technology: EQUAfrac Shaped Charge

Hunting identified the need for a shaped charge that will consistently create entry holes of similar diameter irrespective of centralization or orientation. In many perforating applications it is preferred to have EH diameters in the casing be as consistent as possible to allow for accurate flow area determination. Different EH flow rates can cause issues in future operations. For example, a stimulation operation performed after perforating may not result in equal proppant distribution to all clusters due to EH size variance.

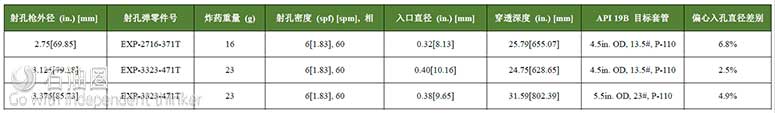

Hunting’s EQUAfrac Shaped Charge is the industry standard in consistent EH diameter while providing the necessary wellbore penetration. The EQUAfrac Shaped Charge achieves a minimum penetration of 2.5 times the internal diameter (ID) of the wellbore to adequately reduce wellbore tortuosity.

Because of the ability to provide a consistent EH and adequate penetration, the EQUAfrac Shaped Charge enables operator to calculate an optimal well stimulation plan and achieve better proppant displacement through the entire length of a stage.

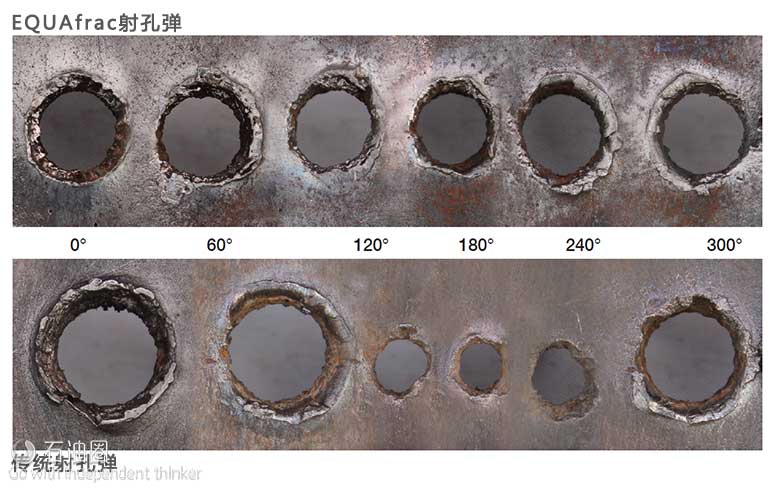

The EQUAfrac Shaped Charge is said to be a ‘True Consistent Hole Shaped Charge’ because of its ability to consistently produce EH sizes with less than ten percent variation.

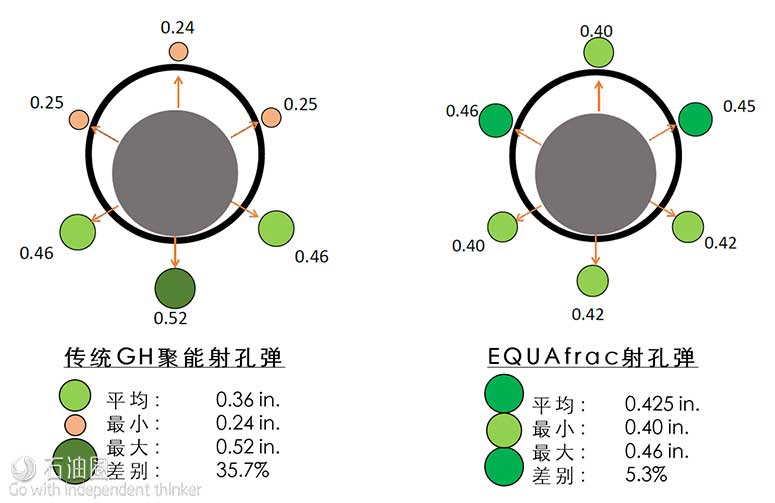

The graphics shown above compare the performance of a conventional GH shaped charge with an EQUAfrac Shaped Charge. In the test, the EQUAfrac Shaped Charge produced a larger EH size with 30% less variation in minimum and maximum diameter.

The EQUAfrac Shaped Charge consistently produces entry holes that have only a four to five percent variation in EH diameter making it the superior shaped charge for perforating in decentralized environments.

EQUAfrac Shaped Charge: Success in the Field

With more than 100,000 EQUAfrac Shaped Charges sold in 2016, Hunting’s clients are reporting that they are extremely satisfied with the consistent hole technology.

In Utah, EQUAfrac Shaped Charges reduced an operator’s injection pressure by 15% compared to a similar perforating gun system using a Super Deep Penetrating (SDP) shaped charge. In West Virginia, an operator reported that because of the EQUAfrac Shaped charge they were able to achieve and maintain a faster pump rate throughout the job. This achievement enabled the operator to improve operating time and reduce stimulation pump pressures.

Another client in the northeast tested the EQUAfrac Shaped Charge in a decentralized perforating gun system against a centralized perforating gun system using SDP shaped charges. The EQUAfrac Shaped Charge delivered a more consistent flow rate that resulted in a higher treating rate: 100 bbl/min vs 91 bbl/min.

Conclusion

Hunting’s EQUAfrac Shaped Charge provides an industry solution for decentralized perforating operations that consistently creates Entry Holes of similar diameter irrespective of centralization or orientation. The technology also provides the customer with cost savings on the perforation of the well with reduction of equipment needed to perform the operation. Additional cost savings comes from the fracking and production side with decrease in injection pressure, an increase in pump rates and higher treatment rates. The EQUAfrac Shaped Charge is another example of Hunting’s new technologies providing solutions to industry challenges.

石油圈

石油圈