Multizone plug-and-perf completions require several zones to be fracked as efficiently as possible to minimize downtime and start production operations.

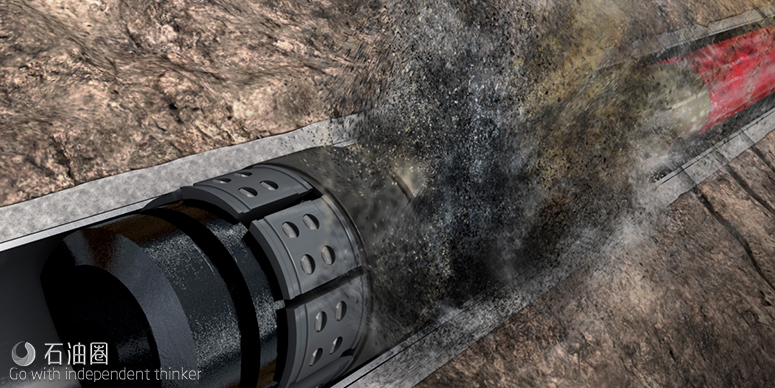

Our Minima composite frac plug isolates the formation for these operations, mills up in 5 minutes or less, and leaves minimal material in the wellbore. Compared to standard frac plugs, the Minima frac plug amounts to 40% less cuttings when flushed from the wellbore.

To fit the needs of your application, the plug is available in both top- and bottom-setting configurations. The top-setting version uses traditional shear screws. The bottom-setting configuration uses a composite shear ring, which safely shears below the plug.

GET SET FOR SUCCESS

With lengths as short as 12 in., the Minima frac plug offers multiple setting styles to fit the needs of your application. A top-setting version uses traditional shear screws, and a bottom-setting configuration uses a composite shear ring, which safely shears below the plug.

Makes short work of wellbore cleaning

In comparison to standard frac plugs, the Minima frac plug it amounts to 40% less cuttings when flushed from the wellbore.

Takes the heat and withstands the pressure

The Minima frac plug can endure pressures up to 10,000 psi (68.9 MPa) and temperatures up to

250°F (121°C).

Cuts circulation time

The lightweight cuttings lift easily to circulate out to the surface during drillout.

What is the material make-up of the Minima composite frac plug? The Minima plug consists of a composite body, composite slips, industry-proven nitrile butadiene rubber (NBR) elastomer, and powder-metal buttons. Created in-house, the composite body has a proprietary filament-wound design.

What is the purpose of the wedge-tip muleshoe bottom? The symmetrical wedge-shaped bottom sub assists with mill-up and allows for uniformed distribution of fluid across the plug outside diameter (OD) when running in the hole. This fluid distribution prevents excessive casing friction or drag on one side, which decreases the risk of pre-setting. By comparison, half or full muleshoe bottom subs tend to push the plug to one side in the casing inside diameter (ID), which increases friction, dragging, and pre-setting risks.

Can the plug be used in a larger casing ID than rated? No, the design is optimized for use only in the published casing ID range. The stroke of the cones, slips, and element system result in this limitation.

What is the purpose of the groove on the OD of the muleshoe? The groove enables installing an elastomeric pump-down ring, which can reduce the amount of water required to pump the plug down the length of the lateral.

How fast can the plug be run downhole? The Minima plug can be run at speeds of up to 500 ft/min (152 m/min).

How long does it take to mill up the plug? The Minima plug mills up in an average of 5 minutes. Under ideal conditions, it has milled up in as little as 2 minutes.

How does the plug set? A The Minima plug is available in both a top- and bottom-setting style. The top-setting style sets using shear screws in the top of the mandrel; the bottom-setting style sets through a composite shear ring under the mandrel.

How much frac pressure can a Minima plug withstand? The plug can hold pressures of up to 10,000 psi (68.9 MPa).

What sealing ball configurations are available? Both top- and internal-ball configurations are available. The top ball can either be dropped from the surface or run in place. The internal ball seals with pressure applied from above, after setting.

How does the Minima compare to legacy plugs? The Minima plug has a number of features that make it truly unique to the market. First, the shortened plug length means that there is less material in the hole, which results in much faster millouts. Second, composite upper and lower slips eliminate the old cast-iron construction, which also contributes to faster millout times.

What sort of testing has been done to qualify the plug? Extensive years of experience in designing and manufacturing composite frac plugs has resulted in a robust testing program that validates all plugs in full scale, real-world conditions. These tests are conducted at specific temperatures and pressures with very stringent pass or fail criteria.

Why does the plug use powder-metal buttons? A The powder-metal buttons break up into smaller pieces during mill-up, which reduces the debris size and extends the life of the drill bit used.

Applications

- Multizone plug-and-perf completions

- Stimulation of unconventional, vertical, deviated, and horizontal wells

Features and Benefits

- Unprecedented short length—just 12 in. (305 mm) for the bottom-setting model—minimizes composite material in the wellbore.

- The composite top slip has a single row of powder-metal buttons, enabling quick drillouts without sacrificing performance. The bottom slip can be configured as either a cast iron ring or a composite slip with powder-metal buttons.

- Beveled bottom prevents the body from spinning, which decreases drillout time for multiple plugs.

- Lightweight cuttings lift easily to circulate out to surface during drillout.

- Optional pump-down ring decreases the amount of fluid needed to pump plugs in the horizontal section.

Tool Description

The Weatherford Minima composite frac plug isolates a formation for fracturing operations in multiple-zone plug-and-perf completions. Thisfrac plug is available in either a top ball or internal ball configuration. After setting, the top ball design seals pressures using a ball run in place or dropped from the surface. The internal ball design seals with pressure applied from above. Minima plugs are rigorously tested to meet high standards. The plug meets or exceeds ISO 14310 and API 11D1 pressure hold criteria

石油圈

石油圈