All wells are different and even wells in the same reservoir can vary greatly in formation characteristics. Surfactant performance varies depending on interactions between the surface active agents, formation mineralogy, reservoir fluids and treatment fluids.

Halliburton’s RockPerm™ service is a laboratory testing process performed by specially trained technicians in local area labs. This process provides pre-stimulation scientific testing with actual formation cuttings, reservoir fluids and stimulation treatment fluids. Then we recommend the optimum surfactant package for a specific well to provide a customized chemical solution to increase well productivity and lower cost per BOE.

Extensive testing has shown that Halliburton’s OilPerm™ surfactants and OilPerm™ Formation Fluid Mobility Modifiers (FMMs) can maximize water recovery and hydrocarbon production from fracture stimulated shale. The objective is better performance from every well every time.

RockPerm Service Input Parameters

• Formation cuttings from the reservoir

• Formation water from the reservoir

• Oil from the reservoir

• Water to be used in the frac treatment

• Proppant to be used in the frac treatment

• Fracturing fluid formulations

• Interfacial properties (IFT, contact angle, adsorption, and physical properties) for each of Halliburton’s OilPerm FMM modifiers

RockPerm Service Output Parameters

• Emulsion tendency

• Fluid compatibility

• Water recovery efficiency

• Water recovery rate

• Hydrocarbon productivity

• Relative OilPerm FMM modifier performance

• Optimized fracturing fluid

Well specific solutions to optimize results

Standard fracturing operations demand the performance of many computer simulations to achieve optimum fracture design to maximize reservoir drainage and productivity. In a similar fashion, fracturing fluid selection is carefully done and tailored through the use of laboratory testing to ensure its ability to achieve the optimized fracture design. Yet, little to no effort is directed to the selection and optimization of fracturing fluid recovery additives which play a major role in the outcome of fracture stimulation treatments.

Every vendor has one or two products to enhance fluid recovery, usually supported by sophisticated surface chemistry information determined in a technology laboratory. While this data can be useful as a guide, it has been found often not to be a good predictor of performance. It is well-known that even minor changes in oil, water or rock composition can have a major impact on the performance of surface active materials.

RockPerm service provides optimization of additive formulations tailored to the needs of individual reservoirs. This unique service takes advantage of Halliburton’s suite (OilPerm FMM modifiers) of unconventional-focused technologies including wetting agents, solvents and demulsifiers integrated into the reservoir-tailored treatment fluid formulation. RockPerm service can provide a large benefit in terms of improved fracturing fluid recovery and hydrocarbon fluids production from your reservoirs.

Case 1: RockPerm service selects optimized OilPerm FMM modifier based on reservoir and fluid properties

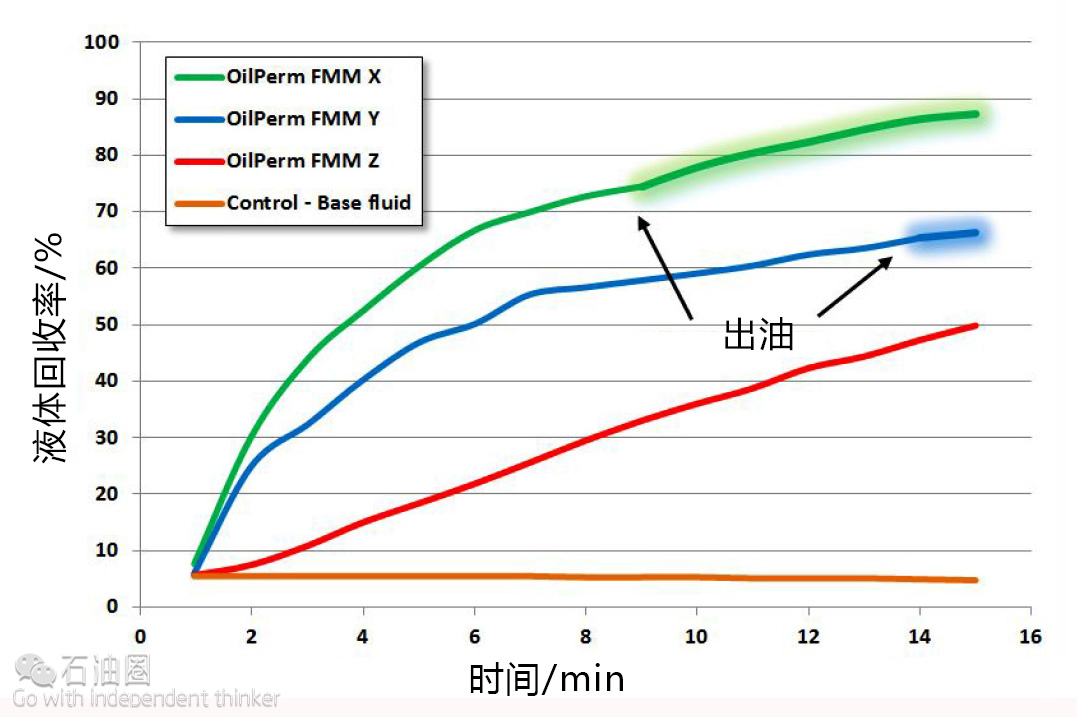

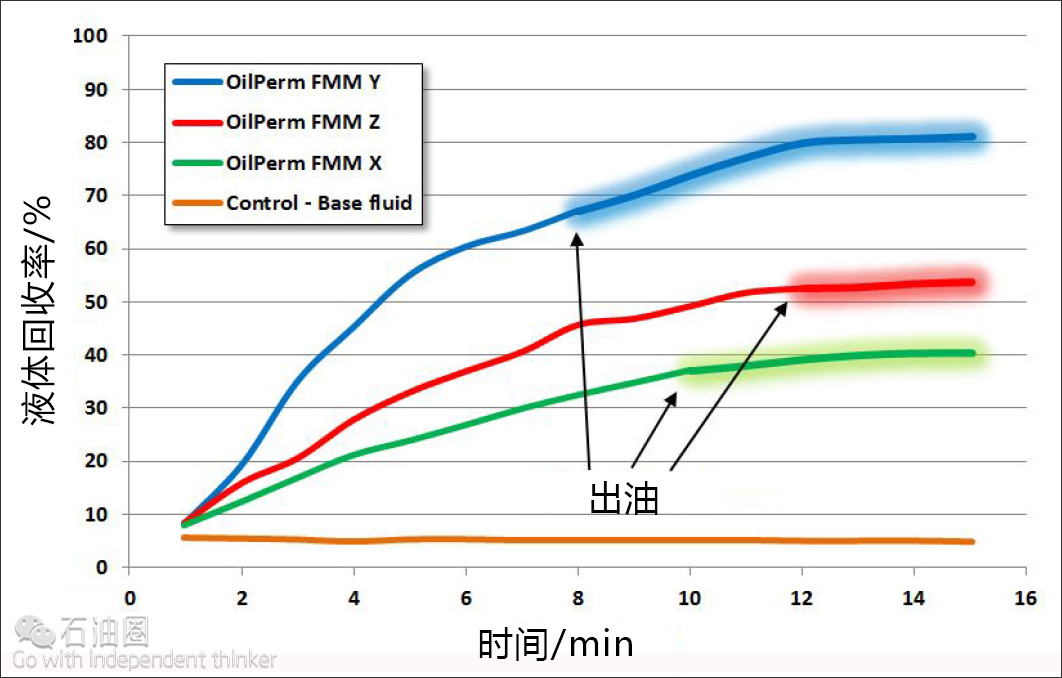

RockPerm service was used on two wells in the same basin to determine the optimal OilPerm FMM. Individual reservoir characteristics (formation oil and formation cuttings) coupled with the scheduled stimulation treatment (broken frac fluid, proppant, and frac water) were incorporated into the testing process to select the optimal OilPerm FMM modifier. Scenario A is an optimization for a well in the Atoka formation which planned to use a borate cross linked guar gel as the frac fluid. From the column flow tests, a specific OilPerm FMM X modifier was recommended due to the highest percentage of fluid recovered and quickest oil breakthrough (Figure 2). Scenario B is a fluid evaluation for a well in the Wolfcamp formation where a slick water fracturing treatment was planned. Clearly, OilPerm FMM Y modifier is the preferred formation fluid mobility modifier for this set of well and fluid characteristics (Figure 3). Even though the two reservoirs are located in the same basin, different OilPerm FMM modifiers were recommended. These tests demonstrate the value of the RockPerm service through its ability to select an optimized OilPerm FMM modifier based on reservoir and fluid characteristics, while under the ‘one-solution-fits-all’ approach the optimal OilPerm FMM modifier would not have been recommended.

The OilPerm FMM suite of modifiers combined with the ability of the RockPerm service to identify the optimal product for each reservoir and stimulation fluid provides the completion design engineer with a new tool to enhance fluid recovery and ultimately oil production.

Case 2 :Wells with OilPerm surfactants and formation fluid mobility modifiers (FMMs) performed 300% better than similar wells on 30-day cumulative oil production

Location: Woodford Shale, Oklahoma

The Woodford shale play covers a large portion of Oklahoma. In Carter and Payne counties, an operator’s wells were experiencing severe post-stimulation declines in hydrocarbon production. Long-term production numbers were lower than expected and desired. The operator turned to Halliburton for assistance in increasing production.

As part of its RockPerm service, Halliburton recommended the use of OilPerm surfactants and OilPerm formation fluid mobility modifiers (FMMs), which are designed to increase treatment fluid recovery and enhance mobility of formation fluids for increased hydrocarbon production following fracture stimulation treatments.

After Halliburton’s recommendations were followed, a study was conducted in four different areas across Oklahoma to compare the effectiveness of OilPerm surfactants against conventionally used surfactants or wells without surfactant. All of the wells in the study were in the Woodford formation and were completed around the same time frame. Results were even better than anticipated. Data showed 69% to 340% increases in initial oil production due to faster and more efficient treatment fluid recovery. After 30 days, the wells treated with OilPerm surfactants had 309% to 559% more oil production due to increased mobility of formation fluids.

CHALLENGES, SOLUTIONS and RESULTS

CHALLENGE 1:Decrease emulsions in produced fluids

SOLUTION 1:Recommended RockPerm service to screen for emulsion tendencies

RESULT 1:Reduced emulsion tendency to lower cost per barrel of oil equivalent (BOE)

CHALLENGE 2:Improve recovery of treatment fluid

SOLUTION 2:Used RockPerm service’s OilPerm products to enable quick recovery of treatment fluid

RESULT 2:Improved initial oil production compared to conventional surfactants

CHALLENGE 3:Increase production of Hydrocarbons

SOLUTION 3:With RockPerm service, selected optimum products to mobilize formation fluids

RESULT 3:Increased cumulative production 300% higher than nearby wells using conventional surfactants or wells without surfactant

石油圈

石油圈