The shape of PDC bit cutters is changing, almost by the week. Innovations in geometry, orientation, cutting structure location and other cutter characteristics are the results of a growing ability to rapidly transition from design concept to practical field application.

In Texas and Oklahoma, a recent series of wells have introduced two variations of a raised profile cutter with a ridge that plows the rock and a novel approach to scribe-type cutters that places them in interruptive, nontracking positions to improve rock failure mechanisms.

Both cutter advances are part of an integrated design process that orchestrates multiple bit characteristics, including blades and hydraulics, using real world modeling and testing. The early success of these and other prototype cutter designs illustrates the flexibility, reliability and speed with which customized solutions are being developed to boost drilling efficiencies in very specific applications.

Raised profile runs

The successful first run of a raised profile TriForce cutter in a West Texas Delaware Basin well was quickly followed by a run in Oklahoma. The second run yielded a 70% ROP increase over offsets using conventional cutters and was equivalent to competitive bits with raised profile cutters. A third run successfully used a second version of this cutter, and the strong performance of the test prompted operator requests for more use of the raised cutters in the future.

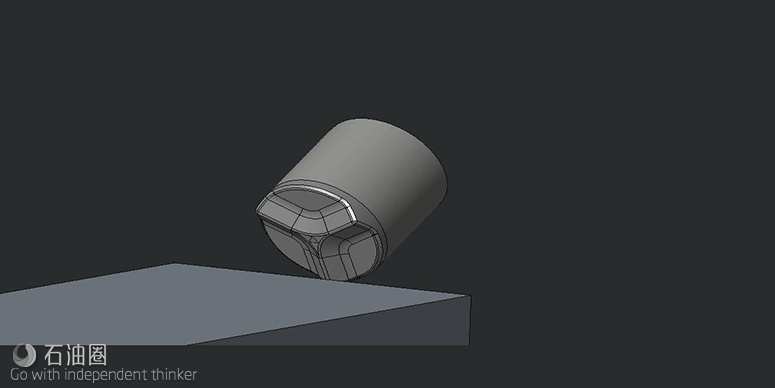

The TriForce cutters feature a ridged profile that concentrates force on a very small leading edge to fracture and plow through the rock (Figure 1). For the same amount of travel, the cutter removes a higher volume of rock to produce greater ROP. The face of the cutter has three raised ridges radiating 120 degrees from the center. The cutters are oriented so that one of the ridges is normal to the formation or perpendicular to the cutting profile. The other two ridges do not engage the formation; the cutter is rotated to align a fresh ridge during bit refurbishing.

The first run of the TriForce cutter was in the Delaware Basin drilling dolomite, limestone shale and sandstone lithology to reach a Brushy Canyon objective. The cutters were installed in primary positions on a 12 1/4-in., six-blade Raider model bit with a Hydra hydraulics package. The goal of the test was to evaluate the validity and performance of the new cutter concept in drilling out the Brushy Canyon.

Prior drilling with this base bit assembly using conventional cutters was very successful, drilling approximately 1,676 m (5,500 ft) at an average 23.6 m/hr (77.6 ft/ hr). With the new cutter, the bit drilled 1,808 m (5,932 ft) at 22.4 m/hr (73.7 ft/hr). The dull condition analysis showed moderate wear to the cutters on par with conventional assemblies in the area. Achieving this performance with a first-generation prototype cutter was very promising.

To further test the cutters, a second run was made in the intermediate section of a central Oklahoma Stack play well. The section drilled through interbedded sand, limestone and shale with moderate to high abrasive potential in the sandstone. The cutters were installed on 8.75-in. six-blade Voyager model bit in primary cutter positions. It drilled 3.2% farther than the average offset interval, and ROP was 70% higher than the average of all offsets and similar to competitive bits with raised profile cutters. The dull had no wear on any cutters, including the TriForce test cutters.

A second version of the TriForce cutters was run in another Oklahoma well. Cutter changes included modifications to the raised profile geometry. Drilling was in the Stack play’s Meramec lateral, a limestone formation with moderate to low abrasive potential. The prototype cutters were installed in primary positions on an 8.75- in., six-blade Voyager bit. It drilled a 352-m (1,155-ft) interval, almost 80% of the offset average, at 8.9 m/hr (29.4 ft/hr), nearly 88% of the average ROP. The performance and a moderate dull grade of the test cutters have encouraged additional runs.

Scribe advances

Innovations in cutter performance also include how they are positioned on the cutting structure. In an Oklahoma Stack well, mounting scribe cutters in patented interruptive, secondary positions resulted in significant performance gains.

The interruptive FANG scribe cutter improves efficiency by prefracturing a smaller contact area, allowing a higher volume of rock to be removed per rotation of the bit.

The novel placement locates the scribe cutters in a secondary position. They may be placed on either side of the cutting path of the standard cutters. The resulting fracture and sweep action of this configuration has shown significant performance gains in the initial application (Figure 2).

The objective of this run was to improve the ROP of the existing bit design. An 8.75-in., six-blade Voyager bit with the FANG scribe cutter configuration was run in the lateral section of the high compressive strength lower Meramec.

The total 1,581.6 m (5,189 ft) drilled was 32.3% above average, and ROP of 21.9 m/hr (72 ft/hr) was 52.8% above average. The scribe cutters were in good condition with a dull grade on par with the area average. The objective was fully met and more runs are planned to document the performance.

Shape of the future

The introduction of these cutter solutions suggests that future advances in drilling efficiency will increasingly include custom designs created to improve very specific applications. Moving quickly and precisely from concept to field application means new options for increasing ROP and footage drilled can be easily and confidently explored.

石油圈

石油圈