Clean water is a precious resource. For decades, nations and companies have been successfully treating water from industrial processes to convert it to contaminant-free clean water.

The oil and gas industry generates an estimated 70 billion bbl of contaminated water from crude oil and natural gas extraction (Boysen et al. 2013). And as reserves are drawn down through production, operators are forced to extract from areas that generate higher volumes of produced water and must implement advanced recovery techniques.

However, these recovery methods can alter water/oil mixtures and reduce conventional water treatment efficiency by up to 50% (Walsh and Henthorne 2012). In addition, regulatory agencies are enforcing stricter water treatment measures such as limiting soluble hydrocarbon emissions. These issues are just some of the produced-water management challenges facing today’s operators.

New water treatment technologies and developments in conventional treatment methods offer a means to solve these problems in managing produced water volumes. ProSep’s Osorb Media Systems (OMS) are providing a unique solution for treating the water coming from chemical enhanced oil recovery (CEOR) operations and removing the dissolved hydrocarbons, including benzene, toluene, ethyl benzene, and xylene (BTEX).

The OMS incorporate Osorb, a powerful adsorption technology that can remove dissolved and dispersed hydrocarbons from produced water in a single step. However, the singular, groundbreaking advance achieved by this adsorption media technology is an integrated, in-situ regeneration process that allows the powerful adsorption media to be used for many years, which eliminates the costly and hazardous media change-outs required with previous adsorption media.

The industry has investigated the use of adsorption media in the past but has found the operating cost too high because of media replacement needs and the operating envelope too limited (Boysen et al. 2013). OMS address both of these challenges by enabling economical water treatment, at a cost as low as $0.07/bbl, and offering applications for removing contaminants that range from heavy dispersed oil to dissolved hydrocarbons and that are effective in the presence of oilfield chemicals.

Osorb Media Systems

The unique structure of OMS created during the manufacturing process is a highly porous, hydrophobic, and organophilic particle (Edmiston et al. 2016). The key characteristic of the technology is the reversible adsorption of organics because hydrocarbons captured during water treatment can be recovered through several different regeneration processes. (The regeneration process is selected for each application based on the end user’s preference and available resources.) Additionally, the media can last for up to 20 years because their effectiveness is retained through the regeneration and recovery process.

Dissolved Hydrocarbons Removal

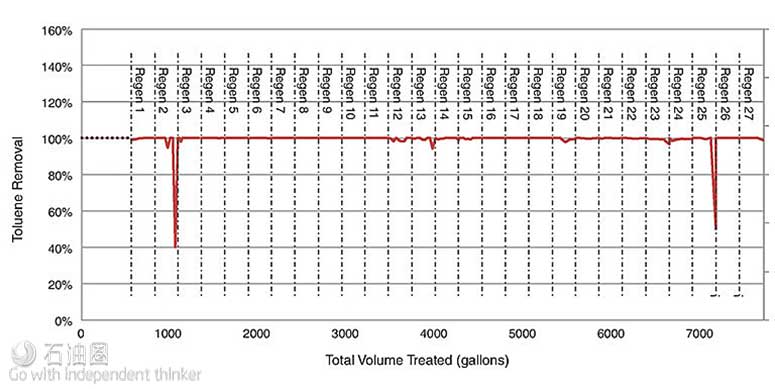

The effectiveness and durability of the media to remove dissolved hydrocarbons like BTEX was evaluated using accelerated life-cycle tests. The OMS removed toluene from water with repeated steam regenerations (completed at 300°F). Fig. 1 presents the removal efficiency measured over the 28 cycles. The media retained 99% efficiency for toluene and capture capacity throughout the testing, which supports previous internal testing results that suggest the media are stable for up to 20 years of use.

The noteworthy observations from the testing include the complete removal of an average 400 mg/L toluene to less than 1 mg/L with a single pass through the OMS. Additionally, the systems maintained less than 1 mg/L toluene concentration even with inlet concentrations as high as 2,072 mg/L.

The performance of the systems in removing soluble hydrocarbons with great efficiency and capacity provide water management teams with a tool that can meet the increasingly stringent regulatory requirements for produced water. The integrated in-situ regeneration of the media provides the cost savings that make the systems an economical technology for soluble hydrocarbon removal.

Dispersed Hydrocarbons Removal

Another issue facing oil producers is dispersed hydrocarbon removal from water associated with CEOR operations. OMS provide a unique approach to oil removal compared with the conventional gravity and chemical treatment methods.

Chemical treatment is costly, and conventional separation (including coalescence, flotation, and enhanced-gravity methods) depends on a significant difference in the density of oil and water and the presence of large oil droplets to achieve efficient separation.

However, during CEOR operations the oil droplets are small, the viscosity is high, and densities of the oil and water are similar, resulting in poor separation. With the OMS, the oil is recovered with great efficiency because it uses strong adsorption forces to remove the hydrocarbons from water.

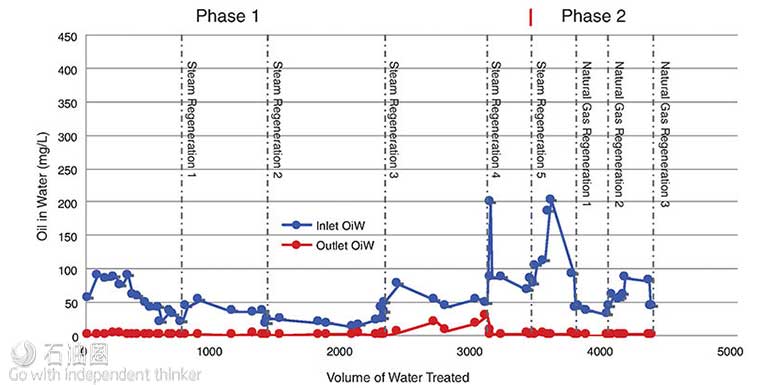

The performance of Osorb with live fluids was evaluated during a technology demonstration in Oman in collaboration with Petroleum Development Oman (PDO) and Qatar Petroleum (QP). Only one Osorb system was used. During this demonstration, an automated pilot OMS was placed inside the Marmul Water Treatment Plant to treat water from a CEOR operation using polymer to increase oil recovery.

The system was placed downstream of the free-water knockout and upstream of the primary water treatment system which consisted of induced gas flotation (IGF) vessels and nutshell filters (NSF). The goal of the demonstration was to reduce the OIW to less than 5 mg/L using only the OMS.

The field trial was completed over 2016 and 2017 and was split into two phases, differing in the method of regeneration. A total of 4,300 bbl of produced water were treated by the OMS with eight regenerations. The reduction of oil in water (OIW) is presented in Fig. 2. The inlet OIW averaged 59 mg/L and fluctuated from 12–202 mg/L over the eight cycles, while the outlet OIW averaged less than 1 mg/L. The media maintained greater than 90% oil removal efficiency after each regeneration cycle.

It was also observed that both regeneration methods were successful. The water treatment efficiency remained above 90%, and the outlet OIW concentration remained at less than 5 mg/L, regardless of regeneration method used. The OMS outperformed both the IGF and NSF currently used, providing a cleaner effluent water to the end user.

Conclusion

The oil and gas industry requires new and innovative technologies that can efficiently meet new regulatory requirements and treat the increasingly challenging types of produced water that are brought to the surface. OMS provide a novel, improved water management option for dispersed- and dissolved-hydrocarbon removal in which the presence of these contaminants can be reduced to a level of less than 1 mg/L, even with the industry’s most difficult-to-treat produced waters. These adsorption media systems achieve an economical solution by offering flexible, in-situ regeneration that eliminates costly and hazardous media change-outs.

石油圈

石油圈