The Halliburton MicroScout service is the first to provide a means of extended stimulation of unconventional reservoir microfractures for increased recovery of hydrocarbons. Enhanced propping agents that are added to the fracturing fluid in specialized stages help ensure that naturally occurring or stimulation-induced microfractures remain open during production and contribute to greater reservoir drainage volume. For even further stimulation, the MicroScout Plus service provides deeper penetration into the formation for increased conductive complexity.

MAXIMIZING RESERVOIR COMMUNICATION TO THE WELLBORE

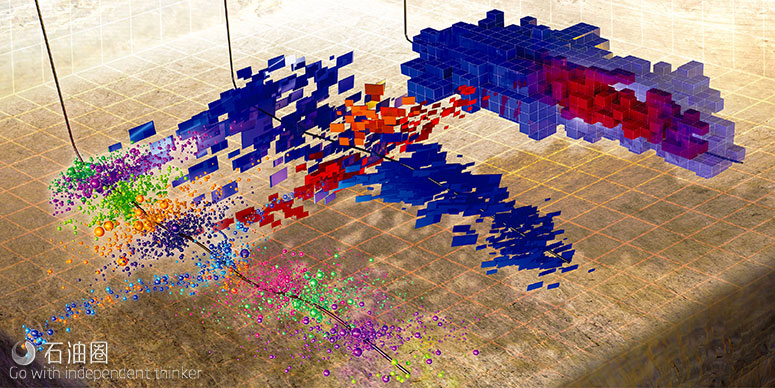

Unconventional fracture stimulation designs can create an extensive active fracture network. Key design aspects help ensure that primary fractures are propped and that the near-wellbore area is open and communicating to the wellbore. Connecting with the natural fracture network and enhancing the number of open and contributing secondary fractures further improve reservoir drainage volume. However, increasing the number of secondary fractures that remain open for the long term during production is challenging.

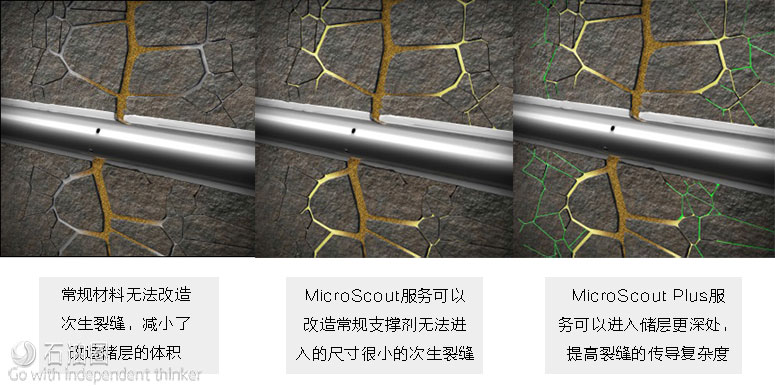

MicroScout service provides conductivity for secondary fractures too small to be propped by conventional frac sand. Placement of proppant, even 200-mesh sand, into natural fractures and microfractures is difficult due to low leakoff fluid velocities. MicroScout service places fine particulates, smaller than 200-mesh size, which can enter the secondary fractures without bridging or screening out at the entrances. After placed inside the microfractures, the low concentration of microsphere particulates helps form partial monolayers, which help prevent the complete closure of microfractures and can provide conductive flow paths connecting the complex fracture network to the primary fractures. These propped microfracture networks enhance the complexity and reach of the stimulation fracture network.

MICROSCOUT PLUS SERVICE: FURTHER ENHANCEMENT OF STIMULATED COMPLEXITY

Fracture network complexity, both natural and stimulation-induced, is prevalent in most unconventional reservoirs. MicroScout service has contributed to improved production from secondary fractures. However, there are fractures that are too small to be treated by MicroScout service and that are left unstimulated, limiting their ability to contribute to long-term production.

To further enhance matrix stimulation, Halliburton developed MicroScout Plus service, which is designed to penetrate deeper into the reservoir. Coupled with the performance-proven MicroScout service, the design is enhanced with additional components to achieve increased stimulation. This two-part system delivers an additional microparticle product (much smaller than original MicroScout service particles) deeper into microfractures and small fissures.

Functioning similar to MicroScout service, the microparticles in the MicroScout Plus service are designed to flow where the stimulation fluid flows. At the conclusion of fracturing operations, a large percentage remains suspended in the fluids and is able to leak off deeper into the reservoir. Once the matrix closes, the microproppant has been placed throughout the created and natural fracture network, allowing for enhanced conductive complexity. MicroScout Plus service can enable stimulation of a larger portion of the created fracture network than has previously been possible, enabling recovery of resources previously untapped by conventional materials

EXPANSION OF THE CONNECTED, CONDUCTIVE FRACTURE NETWORK CAN IMPROVE PRODUCTION

Industry data suggests that, without having an effective means to keep reservoir microfractures open, the well recovery factor and decline curve can suffer. MicroScout service combines proprietary fracturing processes that can greatly increase the complexity of conductive hydraulic fracture networks in tight shale formations, thus maximizing the producing reservoir contact area to enhance microfracture stimulation and recovery factors. Results of an 11-well field study in the Woodford shale play shows that MicroScout service has provided significant uplift to condensate and gas production over the first year of production. A Wolfcamp well treated with MicroScout service in the Permian Delaware basin is outperforming comparable offsets in both initial oil production (by 26 percent) and initial gas (by over 100 percent).

FEATURES

1.Small particulate size for stimulating unconventional reservoir microfractures

2. Service material delivered as a concentrated liquid slurry for simplified handling and mixing

3.Compatible with water-based linear and crosslinked fluid systems

4.Temperature resistant for high bottomhole static temperature (BHST) applications

5.Crush resistant at high closure stress

BENEFITS

1.Decreased decline rates

2.Increased recovery factors

3.Expanded connected fracture network

4.Improved fracturing fluid recovery post-treatment

MicroScout Service Enhances Well Production in Woodford Shale Play

An operator in the Woodford shale play of the Anadarko Basin wanted to improve the stimulated reservoir volume in its wells to improve long-term production. The stimulation designs traditionally used were offering significant stimulation of the primary fractures, but were not sufficiently stimulating the secondary fractures. Adding to the challenge, the reservoir typically exhibited pressure dependent leakoff (PDL), resulting in high-stimulation treating pressures and a high risk of screenouts. As a solution to both, Halliburton introduced MicroScout service, which increased the stimulated reservoir volume and decreased the negative effects of the PDL, resulting in wells that produced up to 15 percent more as compared to offset wells.

When stimulating and producing from the Woodford shale play, there are two issues that are consistently encountered: high treating pressures and steep production declines. High treating pressure can result from the significant degree of fracture complexity associated with the formation. While this complexity can be a benefit to production, it can also be a source of fracture entry friction. The entry friction encountered in the Woodford shale play can range from moderate to severe, and can be characterized by PDL to the secondary fracture network present in the formation. The PDL results in excessively high treating pressures, which limits the achievable treatment rate during stimulation. This can impact treatment efficiency due to a reduced treatment rate or premature screenout.

When wells in the Woodford play are put on production, they often have steep production declines. A potential contributor to the decline is the effect of the secondary fracture network present in the formation (both in situ and generated during stimulations) not being effectively propped open and, consequently, not contributing to production throughout the life of the well. The fractures of the secondary network often have fracture widths that are smaller than the dominant hydraulic fractures, making it very difficult for even smaller proppants to enter the fracture network and prop open the fractures.

SOLUTION

MicroScout service overcame the two challenges encountered here. The MicroScout propping agent is pumped during the pad stages. It decreases the high PDL and the risk of screenout. The MicroScout propping agent enters the secondary fracture network and reduces the fluid leakoff into the network. As a result, treating pressures and the negative effects of PDL are reduced. This minimizes the possibility of a screenout during a treatment. Reducing this risk and improving operational reliability helps improve overall efficiencies, which can save money.

Second, the service provides conductivity for secondary fractures too small to be propped open by conventional proppants. The MicroScout micro-proppant particles are smaller than conventional proppants, so they are capable of entering and propping open secondary fractures, thus increasing the stimulated reservoir volume and ultimately increasing production.

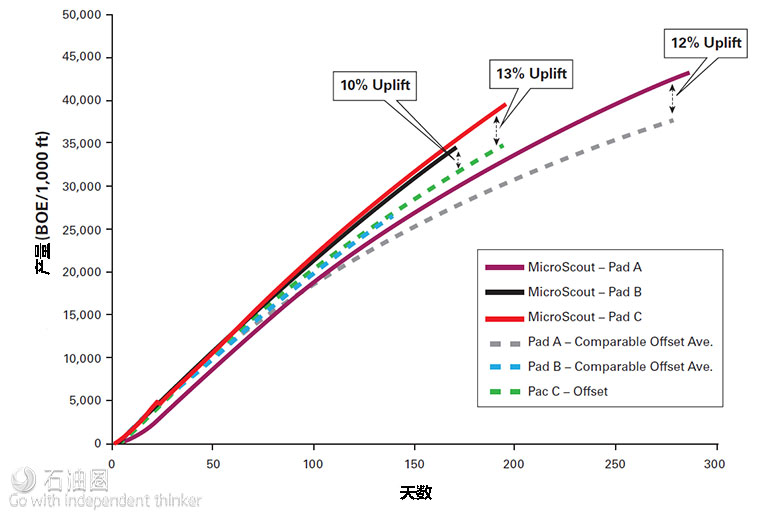

To evaluate the effectiveness of MicroScout service in the SCOOP area of the Woodford shale play, a 12-well field trial was proposed. The field trial consisted of three separate pad locations, with MicroScout service being utilized on one well in each location.

RESULTS

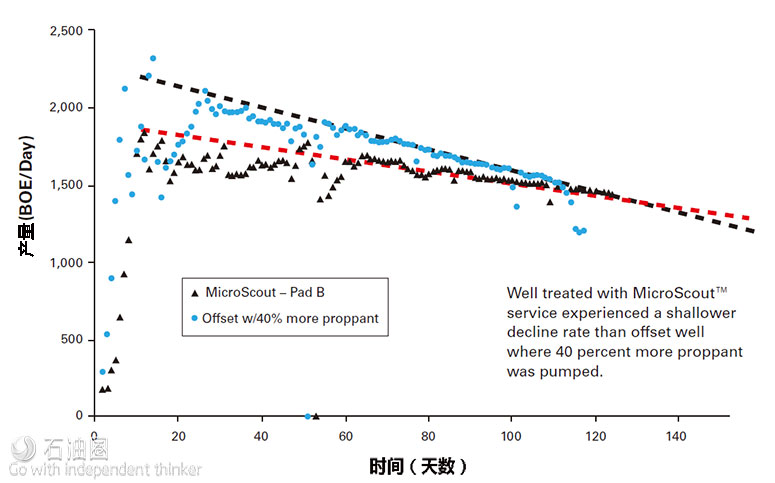

Each pad location consisted of six wells, four wells, and two wells, respectively. The treatments consisted of a standard design; a design that incorporated the MicroScout service; and, on two pad locations, a higher-water-volume design, and a treatment design with 40 percent more proppant. When comparing the production from the wells treated with MicroScout service to wells treated with the traditional design, those treated with MicroScout service showed a 10–15 percent uplift in production. Additionally, the wells treated with MicroScout service proved to have shallower decline rates even when compared against wells where 40 percent more proppant was pumped. The estimated ultimate recovery (EUR) on the wells treated with MicroScout service was approximately 15–30 percent higher than the offset wells. Not only were production benefits realized, but the utilization of the MicroScout service during stimulation treatments also consistently reduced entry friction caused by PDL, leading to lower treating pressures of 500–1,000 psi, which, in turn, has led to more consistency in treatment rate achievement and to more-efficient treatment placement.

石油圈

石油圈