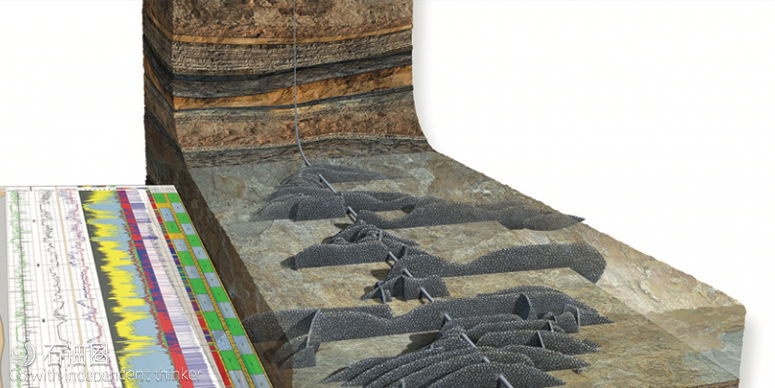

As previously mentioned, in comparison with near-wellbore methods, DCHSA can be considered a mid-field technique. As such, it provides sufficient DOI to assess fracture growth in the formation without any time dependency on when the technique must be applied after hydraulic fracturing. Although this technique has been applied successfully in the Neuquén basin for tight and shale gas reservoirs, its application was limited by the lack of slim acoustic tools for the small-diameter cased holes typical to unconventional wells.

THRUBIT DIPOLE THROUGH-THE-BIT ACOUSTIC SERVICE

To apply the benefits of a detailed sonic investigation in smaller boreholes, a new-generation slimhole tool has been developed for monopole and cross-dipole sonic logging, Fig. 4. The entire optimized structure of ThruBit Dipole* through-the-bit acoustic service is contained in a 2 1/8-in.-OD housing.

The high quality of the dipole measurements obtained with ThruBit Dipole service’s wide-band dipole sources has been confirmed in a variety of borehole and formation conditions, including cased-hole wells. By extending the application of cased-hole sonic anisotropy to the logging of small casing diameters, ThruBit Dipole service enables comparing post-fracture slim dipole log data with a pre-fracture slim dipole log or open-hole log data from the full-size Sonic Scanner acoustic scanning platform.

The tool’s sophisticated sensor section provides fine spatial and frequency sampling for dispersive modes. It has four azimuthal receiver strips, each hosting 12 sensors, spaced every 4 in., which ensures spatial aliasing is not an issue for the sonic processing. Additionally, the collocation of two orthogonal dipole transmitters in the tool supports anisotropy processing without concerns for depth misalignment between the two dipole firings.

3D modeling verification. Research engineers used 3D finite-difference modeling to test component shapes and dimensions, to fully understand and optimize tool response. Unlike other logging technologies, a sonic logging tool is an integrated system that must be evaluated and quantified as such. For example, the geometry, density, compressibility and flexibility of the tool alter the propagation of the measured borehole modes.

Modeling showed that the tool’s novel design largely attenuated the unwanted tool flexural wave in the isolator section, to not interfere with the borehole flexural wave in the receiver section for the frequency band from 2 to 6 kHz. The mechanical strength is maximized without affecting the quality of the monopole and dipole measurements in the fast formations common in unconventional reservoirs.

PRE-FRACTURE DATA: OPEN VS CASED-HOLE ACQUISITION

Application of the mid-field DCHSA technique requires data consistency between the acoustic logging runs before, and after, the hydraulic fracturing job. In this study, the consistency of pre-fracturing data acquisition, using the full-size Sonic Scanner acoustic scanning platform and ThruBit Dipole through-the-bit acoustic service tool, was evaluated. This required performing an additional cased hole pre-fracturing run with ThruBit Dipole service.

Theoretically, the dipole signal should not be highly affected by casing presence or the well’s bonding conditions. The Lajas formation is acoustically considered a fast formation, with compressional and shear slownesses ranging from 40 to 50 us/ft and 90 to 110 us/ft, respectively. However, for this type of formation, the monopole compressional slowness measurement through casing may be difficult to measure and depends heavily on well bonding. Dipole mode in cased hole makes it possible to measure the shear formation slowness in almost all situations, if the tool is perfectly centralized. The comparison in Fig. 5 shows high consistency for the two runs, with both the monopole compressional and dipole shear signals in good agreement. Thus, whether a well is logged pre-fracturing with the full-size Sonic Scanner platform or the slim ThruBit Dipole service, the data consistency with post-fracturing Thrubit Dipole acquisition enables use of the DCHSA technique.

FRACTURE HEIGHT INTERPRETATION

Results of propped fracture height evaluation using the DCHSA technique are shown for three cases. The method was applied using an open-hole run with the Sonic Scanner platform before the hydraulic fracture, and a cased-hole run with ThruBit Dipole service after the hydraulic fracture job. An additional pre-fracturing cased-hole run with the ThruBit Dipole tool was performed for the first two cases, to demonstrate data consistency.

THE VALUE OF A SLIM TOOL

The new-generation slim dipole sonic tool successfully extends application of the DCHSA technique to small-diameter cased wells. Consistencies in the comparison of open-hole logs and cased-hole logs using a full-size Sonic Scanner platform and the slim ThruBit Dipole service, respectively, demonstrate the feasibility of the technique and its flexibility for combining different tools and conditions.

Case study analysis documents that the propped fracture height results provided valuable information regarding the success of the perforation intervals in each fracture stage. Interpretation of the results was key in revising and redefining the hydraulic fracture strategy to optimize well completion costs in the Lajas tight gas reservoir. The results clearly demonstrate that the new slim ThruBit Dipole through-the-bit acoustic service delivers operator value as a viable fracture optimization tool.

石油圈

石油圈