For too long offshore testing has relied on error-prone manual measurement. Both fault-finding and installation tasks have been forced to use downlines of dubious condition and burdensome platform-led testing. This leads to slow and error-prone results.

C-Kore eliminates these problems, allowing testing to be completed much faster by automating the entire testing process and saving you days of vessel time. The tools are not much bigger than a dummy plug and can be fitted on the deck or subsea by diver and ROV.

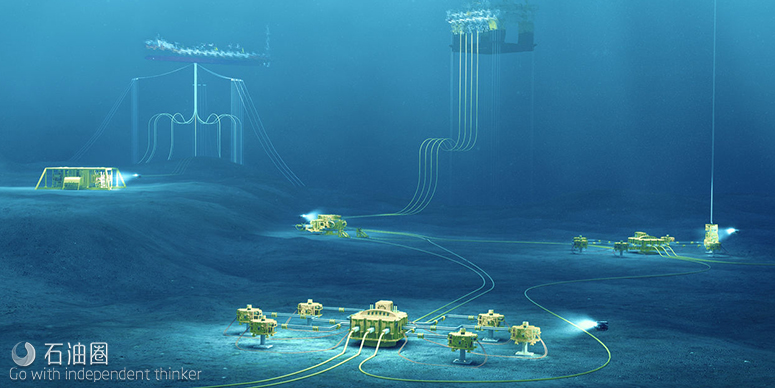

Safe for use on all subsea infrastructure, giving you better data faster.

✔ Electrical cables (umbilicals, power cables, flying leads, jumpers)

✔ Hydraulic and fluid lines

✔ SCMs & SDUs – subsea control modules, distribution units and manifolds

✔ DHPT – down-hole sensors and cables

Find Faults Fast

C-Kore subsea measurement tools find faults and prove the health of umbilicals, jumpers, control modules, down-hole sensors (or anything else) without using downlines. The tools save days of vessel time allowing more to be achieved in every offshore campaign.

Mobilisation and deployment is simple. The measurement program is automated, dramatically speeding up the testing process and reducing the risk of human error. The tools are not much larger than standard dummy plugs, allowing simple hand-carried mobilisation and easy handling for divers and ROV.

- Save vessel time and cost, get more done in every campaign

- Eliminate the delays and uncertainties of downlines and platform-led testing

- Diver safe, simple to use and automated

C-Kore vs. Traditional Methods

C-Kore tools overcome the issues of traditional testing. They remove the problems that plague downline based testing, from the slow deployment and dubious reliability of the downlines themselves to the effects of inclement weather on deck-based reading accuracy. Likewise, as C-Kore units are deployed directly by the intervention vessel there is no longer a need to use slow and cumbersome platform-led testing, where intervention vessels are left waiting for a busy platform to find time for their tests. Both approaches can easily add many hours to every test, adding up to days of vessel time.

By removing the need to use downlines or platform-led testing, C-Kore tools significantly speed up fault-finding operations and reduces downtime required for fault investigation. When deployed by ROV, C-Kore units easily fit in the tooling tray for extremely fast deployment. For divers, C-Kore is lightweight and easy to handle. We use an innovative low-voltage testing technique, so divers do not have to retreat during testing and SCMs are safe from damage. Testing itself is also faster than with traditional methods thanks to test automation and data logging.

C-Kore Cable Monitor

The C-Kore Cable Monitor is a compact automated tool for testing subsea electrical assets. It can be configured in advance by C-Kore System Ltd or set up in the field easily by the end-user. The Cable Monitor is a very versatile product but remains easy to use.

It can be used for both fault-finding and construction campaigns. Compared to downlines or platform-led testing for fault-finding, it is fast and simple to deploy to get accurate data on the health of subsea assets. By measuring directly subsea substantial vessel time and cost savings are made, allowing more faults to be found and fixed with shorter campaigns.

When installing new equipment the Cable Monitor should be fitted as early as possible, ideally just after factory FAT of umbilicals or equipment. It then remains in place during load-out, transit, lay and wet-storage, taking scheduled automated measurements. This eliminates the delays and costs associated with manual measurement. As the unit is deployed along with the equipment, the second end of umbilicals are not deployed blind and asset health can be confirmed all the way to point of hook-up.

The unit is powered by a high-capacity rechargeable battery for stand-alone operation. Simple user configuration is possible with a plug-and-play USB connection to choose what the unit will test and when. Every result is data-logged, with internal storage allowing years of data to be gathered.

C-Kore Subsea TDR

The C-Kore Subsea TDR is a compact automated tool for testing subsea electrical assets. It can be configured in advance by C-Kore System Ltd or set up in the field easily by the end-user. It is simple to use, automating the previously complex work of driving a TDR.

The TDR is normally used in tandem with the Cable Monitor for fault-finding. Once the Cable Monitor has narrowed the location of a fault to a single component (for example an in-field umbilical) the TDR is used to precisely identify where in the cable the fault resides. This knowledge can be used to inform repair versus replacement strategies. By measuring directly subsea, the problems of deck-based downline testing are eliminated, including impedance mismatches, offset errors, faulty downlines and the difficulty of driving the TDR correctly.

For new asset installation the TDR can be used to characterise cables for future reference and find discontinuities in impedance that have not effected the insulation resistance. As this testing is automated, vessel time and personnel requirements can be reduced to achieve cost savings. The unit can be deployed subsea to take TDR readings directly once installation is complete.

The unit is powered by a high-capacity rechargeable battery for stand-alone operation. Simple user configuration is possible with a plug-and-play USB connection to choose what the unit will test and when. Every result is data-logged and the unit has built-in software for result analysis.

C-Kore Pressure Monitor

The C-Kore Pressure Monitor is a simple but versatile tool for monitoring fluid lines during asset installation, for example umbilical cables. It is very compact allowing easy integration onto stab-plates and test fixtures.

When installing new assets the pressure monitor is used to prove that the fluid lines have been correctly pressurised and detect any leaks that occur, removing the need for manual measurement. The units can be deployed subsea with the equipment and remain fitted during wet-storage until the point of hook-up. The pressure monitor can be connected to a nearby Cable Monitor or TDR to show results on the display. It is also possible to daisy-chain multiple pressure monitors together for measuring different fluid lines. Every reading is timestamped and stored in internal memory.

The unit is powered by a high-capacity battery for stand-alone operation. Simple user configuration is possible with a plug-and-play USB connection.

石油圈

石油圈