C6 Technologies has announced the completion of an application of its ComTrac technology in conjunction with its parent company, Archer.

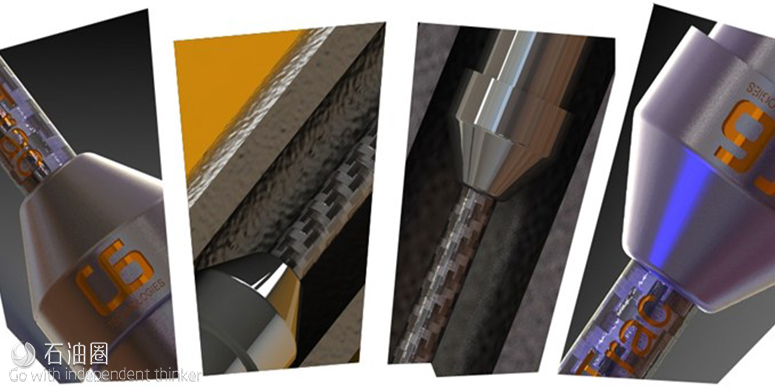

ComTrac is the only system in the world that comprises a reel of spoolable 12-mm diameter semi-stiff carbon composite rod with electrical conductors, according to the company. To date, the technology has been proven to operate at lengths of up to 8 km. C6 Technologies plans to extend this significantly with applications exceeding 12 km.

The two-week project in the Norwegian North Sea, which was operated by Archer, is the first time the composite rod has been used with a tractor. This enables intervention beyond the capabilities of conventional wireline technology in terms of length and load, particularly for horizontal wells, the company said. The scope included fishing, fluid saturation logging and perforating with long sections of high shot density guns.

The low friction, stiffness and almost non-existent stretch of the carbon composite rod eliminate the problem of “stick and slip” experienced with wireline cables. This enables ComTrac to deliver exceptional data quality and repeatability, particularly for high-resolution logging services such as fluid saturation logs, according to C6 Technologies.

The ComTrac system also demonstrates superior strength and lift performance when carrying heavy loads, allowing for longer tools and perforation guns to be deployed, the company said.

“ComTrac is now available as a commercial solution, and Archer is in the process of rolling out a number of new applications worldwide,” Hans Kristian Hegland, CEO of C6 Technologies, said, “Wells are getting deeper and longer, and today there are limits to how far current intervention technology can go. The latest project with Archer demonstrates the versatility of ComTrac and its ability to perform on a wide range of applications and environments. The next step is to expand the operation limits of the technology to 12 km and beyond.”

C6 Technologies is a joint venture between Archer and IKM. The ComTrac system is designed and manufactured by C6 Technologies and operated by Archer.

C6 Technologies’ ComTrac well intervention technology can significantly exceed capabilities of conventional wireline technology in terms of length and load, particularly for horizontal wells. It compromises a reel of spoolable 12 mm diameter semi-stiff carbon composite rod with electrical conductor.

ComTrac® is an innovative intervention system designed to convey electrical, electro-mechanical, and mechanical services within the same rig-up. It offers a cost-efficient alternative to a broad selection of conveyance challenges, along with the ability to access wells not currently feasible with conventional conveyance methods.

Carbon composite materials have enabled significant advances in the aerospace, automotive and manufacturing industries due to their unique properties. Archer, together with C6 Technologies, has brought these advances into the well intervention arena with the development of a semi-rigid composite rod encapsulating an electrical conductor. Carbon composite construction brings high strength and low weight compared to conventional cables with the added advantage of being able to enter wellbores not accessible with gravity alone. A heavy duty electrical conductor allows both logging services and high power electro-mechanical tools to be run.

Designed from the outset with ease of operation in mind, ComTrac® offers flexible rig-up to enable operations even in areas where space is at a premium. Direct line of sight between unit and well is no longer required, and the unique Bend restrictor technology allows fully flexible routing to the injector head while enclosing and protecting the rod.

At the heart of the ComTrac® system is a stiff carbon composite rod with electrical cables embedded for communication with downhole tools. It is driven in and out of producing wells by the standalone ComTrac® surface unit.

Flexibility gives operational benefits

- Mechanical and logging capability: No need to rig over betvreen SL and e-I ne drums or units

- Large and heavy BHA: S-raddles, perforation guns

- Precise control of toolstring movement: high quality logging data, Controlled movement for milling/injetting

- Ability to “push”: lighly deviated wells with reduced or eliminated tractor needs

- Low POB: Multiskilled 3 man crew per shift

- Flexible rig-up: No need for“line of sight”, Absence of high tension lines

- Slick and stiff rod: Lower friction and increased rigidity gives longer reach, simplified PCC without crease

- Strength to weight: Twice the strength at one third of the weight of regular wirelines

- Less stretch give better depth accuracy: One fifth of the stretch coefficient of regular cables

- Electrical conductor: Can convey mechanical interventicn and electrical tool string, Large conductor allows high power tools

- Sour service: Resistant to H2S and CO2

On a recent field trial, Comtrac system successfully completed world’s first:

…intervention with a semi-stiff composite rod with monoconductor

…rig-up without line-of-sight or high tension lines using bend-restrictors

…jarring with a composite rod

…plug retrieval with a composite rod

…logging with Multifinger Caliper/GR/CCL on a composite rod

…suction/jetting intervention job with a composite rod

石油圈

石油圈