Reveal Energy Services has announced that it has produced and delivered the first near real-time DiverterSCAN technology results, which allowed an operator to identify a diversion design that enhances hydraulic fracturing fluid distribution.

An operator asked Reveal Energy Services to determine if the diverter was successful in stopping one cluster from taking most of the hydraulic fracturing fluid and causing one dominant fracture. The goal is to choose a diversion design that prevents this one dominant fracture by forcing the fluid into all of the clusters to stimulate the entire stage.

But, identifying the right diversion has never been quick until now. Operators wait as long as 90 days or more for production data to validate diversion effectiveness. DiverterSCAN technology, based on pressure data acquired from a simple pressure gauge attached to a wellhead, offers this information in near real time at a fraction of the cost. The operator was able to choose the right option that stimulated multiple clusters, based on the technology and the analysis by the company’s geoscientists and engineers.

“Operators are using DiverterSCAN technology to identify and choose the diversion design that yields the best results,” said Sudhendu Kashikar, CEO of Reveal Energy Services. “With this understanding, operators can increase hydraulic fracturing efficiency on every pad in the field.”

The pressure data acquired from a monitor well, which informs DiverterSCAN technology, are the foundation of the company’s four other services:

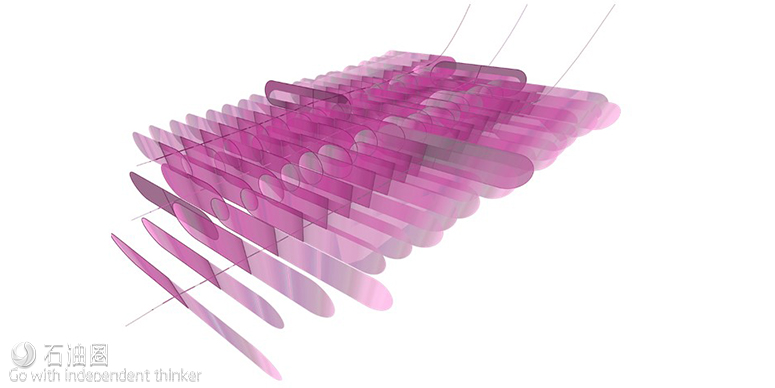

- Improve total fracture geometry:FracSCANSM technology accurately quantifies 3D fracture maps of half-length, height, and asymmetry. The maps allow operators to improve treatment design and well lateral-spacing decisions, in addition to evaluating formation interactions or frac barriers and understanding stress-shadowing effects.

- Reduce nonproductive fluid loss: DepletionSCANSMtechnology identifies the depletion boundary surrounding a parent well so operators can reduce nonproductive fluid loss to improve treatment effectiveness. The resulting depletion map offers information about the extent of repressuring the reservoir following a protection refrac.

- Improve cluster spacing decisions: PerfSCANSMtechnology improves cluster spacing decisions by highlighting the fluid distribution within a stage. The technology offers a clear understanding of pumping rate effects on fluid distribution.

- Optimize effective reservoir contact: ProppantSCANSMtechnology offers unprecedented insight into the fluid system and pump schedule for transporting proppant so operators can optimize effective reservoir contact.The identified propped fracture dimensions answer the question: “Where did the proppant go?”

- Enhance fluid distribution: DiverterSCANSMtechnology lets operators know if the diverter is slowing down or stopping primary fracture growth and enhancing fluid distribution within a stage. Multiple diverter drops can be evaluated in time for improved field decisions.

All five services are powered by simple, accurate, affordable IMAGE Frac™ pressure-based fracture maps that can be applied on every well without interruption to hydraulic fracturing. Operators have applied the company’s fracture maps to understand more than 2,000 stages in formations throughout the US and Canada.

Validate Your Completion Design on Every Well with Minimum Operational Risk, and Cost

IMAGE Frac™ 2.0 pressure-based fracture maps enable you to optimize a stimulation treatment by applying fracture intelligence on every well. You can approach work in a new way with this simple, accurate, affordable technology that determines whether you need to change the treatment to match a development’s varying geology.

All you need is a bridge plug and a pressure gauge that monitors a few frac stages. Hydraulic fracturing proceeds without downhole tools, downtime, or additional crew.

Reveal Energy Services validates more than 2500 hydraulic fracturing stages

Reveal Energy Services has announced that it has validated more than 2500 hydraulic fracturing stages throughout the US with its simple, accurate, affordable pressure-based fracture maps. The technology has been successfully deployed in the Bakken, Midland, Delaware, Eagle Ford, STACK/SCOOP, Woodford, and Marcellus.

The fracture maps, which are created in relevant time, show an operator the fracture half-length, height, and asymmetry for validating the completion design on every well at a fraction of the cost of legacy diagnostic technologies. The maps easily quantify this fracture geometry so operators will know whether a stimulation treatment is producing the planned fracture dimensions. All that is required is a pressure gauge and a bridge plug on a monitor well; hydraulic fracturing proceeds in the treatment well without downhole tools, downtime, or additional crew.

“Instead of monitoring only 5% of their wells with older technologies that are complicated, intrusive, and expensive, operators can now monitor 100% of their wells with our streamlined pressure-based fracture maps,” said Sudhendu Kashikar, CEO of Reveal Energy Services. “Our technology guides operators to work with factory mode consistency that increases reservoir contact.”

The company’s project turnaround time continues to decrease significantly. In December, Reveal Energy Services announced the first near real-time DiverterSCANSM technology results, which allowed an operator to quickly identify a diversion design that enhances hydraulic fracturing fluid distribution. The operator is increasing fracturing efficiency by stimulating multiple perforation clusters in its STACK/SCOOP wells.

石油圈

石油圈