In turbulent times, optimizing the performance of existing wells is a practical choice that reduces the costs and risks associated with well intervention. Innovative coiled tubing (CT) technologies offer several key benefits, including reduced footprint, accurate measurement of bottomhole pressures and temperatures, proper depth correlation, and precise load measurements, in a unique, robust package for harsh environments and complex systems. This information enables operators to make educated decisions as the job progresses, respond immediately and adjust job parameters as conditions change, and eliminate guesswork.

ACTive live downhole coiled tubing services

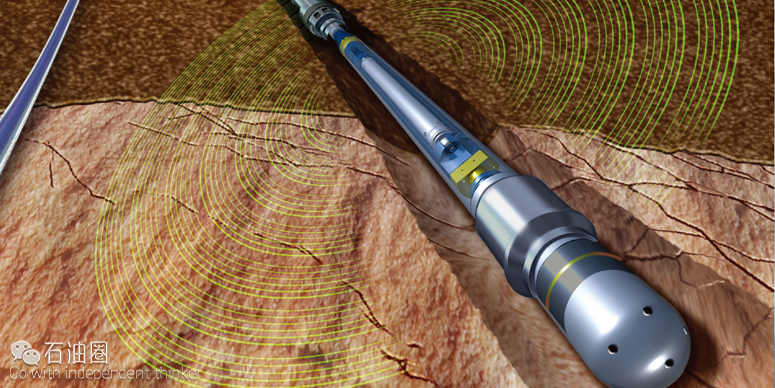

ACTive services provide real-time measurements, including internal and external pressure, temperature, casing collar locator (CCL) depth correlation, and distributed temperature measurements, conveyed through fiber-optic telemetry. Resistant to acid and H2S, these real-time CT services give you the opportunity to monitor and evaluate job progress in any well, to optimize treatment results, and to intervene with one trip in hole.

01 Use accurate well diagnostics to make decisions

Customize designed well treatments onsite

The ACTive PTC* live CT pressure, temperature, and casing collar locator tool delivers measurements to surface in real time.

Controlled stimulation requires accurate location and placement of downhole tools.

Real-time pressure, temperature, and casing collar locator measurements improve job efficiency and subsequent well performance.

New proprietary technology enables operators to design an entire treatment based on live monitoring of pressure, temperature, and injection rates. These real-time measurements— including pressure, temperature, casing collar locator, gamma ray, and tension and compression modules—enable operators to accurately determine the depth of the tool end, whether the weight applied on surface is transmitted to bottom, the reservoir response, and whether the pressure applied is adequate.

APPLICATIONS

- Flow contribution and production diagnostics

- Stimulation and diversion effectiveness

- Water-injection profiles

- Multiple injection evaluation treatments

- Well kickoff

- Sand cleanouts

- Accurate bottomhole pressure management

BENEFITS

- Improve decision- making with real-time downhole pressure

- Respond quickly to changes in temperature

- Achieve accurate depth correlation with casing collar locator measurements

FEATURES

- Ability to convert electrical to optical Onboard diagnostics

- Ability to combine real-time digital telemetry–based diagnostics with other measurements

- Real-time depth correlation with completion via casing collar locator

- Real-time internal and external CT pipe pressure and temperature

- Wireless surface communications Fast-rate telemetry

- Plug-and-play compatibility with the majority of CT downhole tools

- Innovative proprietary system to enable job-optimization decisions in real time on a single trip

CASE STUDY

CT stimulation service helps Saudi Aramco double production in water-wet wells

An operator needed to use CT to effectively stimulate wells with high water cut and eliminate the risk of increasing water cut due to acidizing. Using the ACTive PTC tool, the operator was able to monitor injection rates and downhole pressure and temperature. This monitoring enabled maximum fluid penetration and successful isolation and stimulation of the oil-producing zone, with a 30% decrease in water cut and 3,000 bbl/d of incremental oil production. The combination of the ACTive PTC tool with DTS allowed for precise monitoring of treatment evolution and on-the-spot job volumes and parameters modifications.

02 Correlate against the formation

Retain pumpthrough capabilities while logging

The ACTive GR* live CT gamma ray logging tool detects gamma rays in the formation in real time while maintaining pumpthrough capabilities for CT interventions.

Using gamma ray data is an effective and accurate way to evaluate a formation and conditions.

Gamma ray tools record naturally occurring gamma rays in the formations adjacent to the wellbore to accurately measure the radioactive content of the formations. Effective in any environment, gamma ray tools are used to correlate logs from cased and open holes.

When combined with ACTive services, this technology enables correlation while maintaining pumpthrough capability for CT interventions. The measurements gathered during depth correlation can be used in conjunction with other CT services to further enhance an intervention’s effectiveness.

Application

- Accurate depth correlation

- Qualitative evaluation of lithology

- Radioactive tracer monitoring

- Perforating or abrasive jetting in a single run

Features

- Ruggedized version for use during perforating operations

- Design that accommodates ball drop to enable activating tools below

- Plug-and-play combination with other services

- Pumpthrough capability for CT intervention and gamma ray log in same run

- Accurate gamma ray correlation for precise identification of downhole conditions

BENEFITS

- Real-time correlation-Provides industry-standard measurements

- Pumpthrough capabilities-Enables CT intervention and gamma ray log in one run

- No need for wireline unit-Reduces footprint at the wellsite

CASE STUDY

Overcoming severe drilling damage

While drilling a K-carbonate gas well in the Middle East, an operator encountered high fluid losses due to lost circulation material, which caused severe damage to the near- wellbore formation and had low solubility in acid.

To accurately perform abrasive jetting to place notches that extended through the damaged area, the ACTive GR tool was used to obtain gamma ray measurements in real time and identify the precise depth to perforate in every thin interval with high gas saturation. This information enabled the operator to save time compared with existing conventional methods of depth correlations, which require two separate runs.

This successful placement identified by the ACTive GR tool brought production online quickly to achieve the field’s highest post perforating gas flow.

03 Effectively manipulate wellbore hardware

Detect even the smallest changes in weight downhole

The ACTive TC* live CT tension and compression tool provides downhole load and torque measurements in real time through fiber-optic telemetry.

When a remedial operation is necessary, efficiency is key.

Reducing operational time during CT retrieval and fishing minimizes deferred production and the time and resources wasted while the operation is ongoing. With real-time downhole information, job parameters can be adjusted immediately throughout the intervention.

New tension-compression technology provides downhole load and torque measurements while also maintaining pumpthrough capability. The measurements are conveyed to surface on CT that is enabled by fiber-optic telemetry for faster evaluation and reduced errors

BENEFITS

- Improved accuracy with real-time downhole measurements

- Greater efficiency and control

- Reduced risk of unsuccessful operations

APPLICATIONS

- CT operations in deviated and horizontal wells

- Positive indication of latching or jar activation

- Confirmation of sliding sleeve activation

- Confirmation of completion hardware manipulation

- Positive indication of inflatable packer setting

- Indication of perforating guns firing

FEATURES

- Downhole load and torque measurements in real time

- Robust design for use during perforating and fishing operations

- Pumpthrough capability to allow CT intervention in the same run

- Ball-drop capability through the tool for activation of tools below

- Plug-and-play combinability with enhanced ACTive services

CASE STUDY

ACTive TC tool enables shifting of 10 ICDs in horizontal wells within 6 hours

An operator needed to access inflow control devices (ICDs) in horizontal wells to confirm opening of sleeves and determine the status of the sliding sleeves during the operation, and wireline was unable to reach the depth of the ICDs. Using the ACTive TC tool, the depth of the CT was correlated to the position of ICDs using the casing collar locator feature. Once the dog collars were confirmed to be open, the ACTive TC tool was moved up and latched onto the ICD sleeve. A total of 10 ICDs were shifted within 6 hours versus more than 12 hours by using conventional toolstrings, and a DTS survey evaluated the opened sleeves.

石油圈

石油圈