CASED-HOLE LOGGING

Cement evaluation

Ensuring well integrity requires accurate cement-bond evaluation, which in turn requires good acoustic coupling between the cement and the casing. There are two parallel approaches for accomplishing this: (1) improving the cement bond (adhesion strength) with the casing; and (2) improving cement-bond evaluation in the presence of debonding via new tools and interpretation models.

In the first category, a variety of chemical agents, including surfactants and expansion agents, have been suggested as additives to the cement or spacer to improve acoustic coupling. Two recent papers have proposed latex, as well as a combination of an optimized surfactant and mud-removing fiber.

In parallel with these efforts, other methods have investigated modifications to the casing outer surface to improve casing-cement adhesion. Grit blasting, which removes mill varnish and leaves a rougher surface that improves bonding, is one such method. However, newer carbon-steel casing is naturally hydrophobic and resists cement bonding. Shell, in collaboration with Oceanit, has created a new steel-cement interface nanobond (SCIN) that uses a patented technology to create a surface morphology on the outside of grit-blasted casing that is hydrophilic (the process changes the wettability of the steel surface) and chemically reactive to cement, Fig. 6. Field tests demonstrated that in certain conditions, this process can improve acoustic coupling (i.e., cement-bond evaluation), even after multiple thermal and pressure cycles.

Ongoing research efforts to improve the quality of cement evaluation have investigated the use of additional acoustic modes, e.g., slow Stoneley wave and shear horizontal. Another study proposed using a combination of ultrasonic and sonic logging data, in a new processing method, to distinguish between wet and dry microannulus.

A recent paper proposed the concept for an electromagnetic cement-evaluation method, using a multi-sensory magnetic-susceptibility-type tool and magnetic cement slurries. The modeling study suggested that creation of microannulus, with accompanying contamination of the magnetic cement slurry by drilling fluid, would reduce the magnetic permeability of the cement slurry. By monitoring magnetic field strength, the proposed EM tool could, in theory, distinguish variations produced by debonding between the casing and cement. A review of recent trends in use of cement-evaluation logging technologies discussed the potential for oxygen activation, neutron-neutron and X-ray logging —technologies that heretofore had not been used for this purpose.

Pulsed-neutron logging

After extensive field-testing, Weatherford launched its new cased-hole evaluation system (Raptor 2.0). The tool employs a five-detector array and four spectroscopic gamma-ray sensors that allow the tool to provide formation evaluation, production, logging, and well-integrity measurements. The larger detector array increases tool sensitivity, as well as the tool’s depth of investigation. The lanthanum-bromide gamma-ray sensors have improved peak resolution and signal-to-noise ratio, which increase the tool’s sensitivity to gas saturation and enable dimensional oil-saturation measurements. The tool uses enhanced sigma and carbon/oxygen modes for oil-water saturation in saline and freshwater formations. The tool can identify the locations and volumes of bypassed oil and gas, and can identify and correct for carbonate lithology and cementation effects.

The unique N-Vision mode is capable of quantifying gas-liquid saturation at porosities as low as 5%. An oxygen-activation mode is used for production and well integrity operations. New software workflows provide integrated petrophysical characterization. The 111/16-in. tool can be run in all mud types and is suitable for borehole diameters ranging from 2 to 18 in. It has a 12-in. vertical resolution, a depth of investigation ranging from 7.6 to 15.8 in., and is rated to 300°F and 20,000 psi.

Pipe integrity

Halliburton has introduced a new electromagnetic corrosion inspection service (Electromagnetic Pipe Xaminer V) that can quantify metal loss in up to five concentric strings of pipe. The frequency-domain induction tool has two low-frequency multifrequency transmitters (up to 16 frequencies between 0.5 and 100 Hz) and eight receivers, Fig. 7. Optimized transmitter-receiver spacing configurations and multi-frequency operation enable the tool to assess the metal loss in each individual pipe string. The transmitters induce eddy currents in the surrounding metal tubulars, generating a waveguide mode and a lateral-wave mode. The receivers measure the electromagnetic field induced by the currents that flow in the near-field, transition, and far-field zones. The measured signal provides a total-thickness calculation for determining pipe integrity.

An inversion method is used to identify the location and magnitude of corrosion-induced defects, i.e., metal loss, in each concentric string. The 11/16-in. tool is run centralized at a current maximum logging speed of 15 ft/min, and can be combined with other cased-hole diagnostic logging tools. The minimum tubular outer diameter is 23/8-in., maximum outer diameter of the first tubular is 7-in., maximum casing size is 24-in., and the maximum total metal thickness is 2½-in. The tool is rated to 350°F and 15,000 psi, and operates in continuous mode on either monoconductor wireline or slickline (in memory mode). Slickline operation allows rig-less intervention.

Production logging

Most conventional production logging methods have difficulty providing accurate quantitative inflow profiling in horizontal wells producing at low rates (<150 m2/D), due to the decreasing reliability of the measured data as borehole inclination increases. Schlumberger reported on an experimental prototype tool designed to measure inflow profiles in low-rate horizontal wells. The tool, which is based on an azimuthally distributed array of six thermal anemometers to determine inflow profiles, would provide an additional diagnostic dataset used for characterizing fluid inflow. The sensors records overheating profiles along a well; overheating profiles depend on the local velocity of the fluid and its phase composition. The periodic heating regime of the sensor enables measurement of the undisturbed fluid temperature for determination of overheating and acquiring high-resolution temperature profiles.

RESERVOIR MONITORING

Distributed acoustical sensing (DAS)

A study seeking lower-cost alternatives to geophones for VSP surveys found that DAS receivers: 1) can provide time-depth curves comparable with those of the geophone, but require a precise depth calibration; 2) are less suitable for amplitude studies than geophone or hydrophone receivers, because their directionally dependent sensitivity makes DAS first-break amplitudes less reliable; 3) cased DAS receivers can produce good-quality reflections comparable with that of the geophones, however loose DAS is affected by tube-wave contamination, similar to that of hydrophones; and 4) F-K analysis between physically coupled and passively coupled receivers for all three receiver types is comparable.

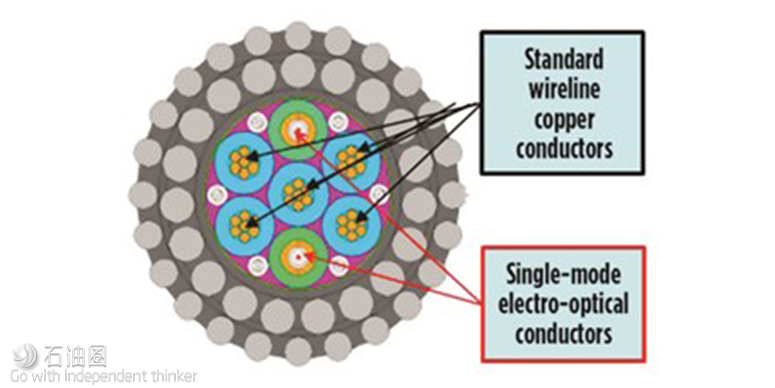

Hybrid electro-optical cable

The development of electro-optical hybrid cable allows conventional wireline logging and single-component time-depth and velocity data to be conducted simultaneously on the same run, thereby reducing rig time significantly, Fig. 8. This option is preferred to using a separate run of geophones or dip-in DAS fiber optic, The fiber-optic cable conductor of the hybrid cable is connected to independent DAS acquisition unit at surface that collects seismic data in parallel with logging operations. This system is undergoing field trials.

Disposable fiber-optic sensors

An innovative system of disposable distributed fiber-optic sensors has been designed to provide a low-cost and low-risk deployment method for fiber-optic sensors. The Well-SENSE system uses “bare” fiber optics that are deployed by free-fall into the well. Following data acquisition (typically several hours), the system is disposed of in the well. Tests indicated that the fiber can be deployed successfully and reliably in a well, and that a DAS survey can be performed on each fiber installed.

Multi-component seismic with DAS

The use of multiple helically wound optical fibers can provide directional strain data to enable high-resolution multi-component DAS data. Researchers at the Colorado School of Mines propose a configuration of five equally spaced constant-pitch helical fibers and one straight fiber, to obtain the six different strain projections needed to reconstruct all components of the 3D strain tensor at a point along the fiber.

石油圈

石油圈