Pressure Control Innovations Improve Reliability

A new valve design and enhanced condition monitoring system lowers total cost of ownership.

Although there has been some recovery and stabilization in market pricing, rig day rates are still down from their historical highs. Contracts remain elusive, and differentiation with upgraded equipment and technology packages are effectively the only way for one contractor’s rig to stand apart from the rest. The oil and gas industry continues its search for meaningful cost-cutting measures that will allow idle rigs to get back to work. To this end, National Oilwell Varco (NOV) has pursued improvements in its pressure control products to lower the total cost of ownership by improving reliability and reducing required maintenance.

New valve design

The Low-Shock subplate mounted (SPM) valve designed by NOV is the first major SPM valve development in almost four decades and addresses the most common failure modes caused by water hammering, corrosion and assembly induced infant mortality.

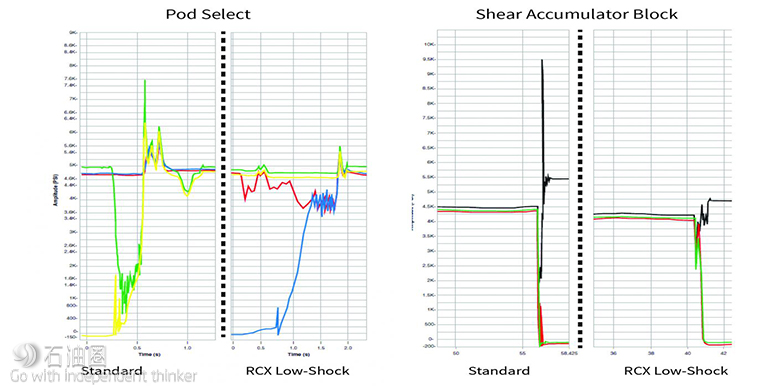

The new design has shown improved performance and has the potential to reduce circuit failure due to a reduction in hydraulic shock (Figure 1). By controlling the timing of the valve shift, hydraulic shock was reduced from nearly 10,000 psi to just over working pressure in the most extreme cases. The SPM pilot shifts the valve in less than a second with no interflow. This controlled shift reduces the end rush of hydraulic fluid, protecting downstream components during valve opening and upstream components during valve closure.

FIGURE 1. These performance graphs show comparisons between standard SPM valves and Low-Shock SPM valves. (Source: NOV)

In addition, although previous versions of the valve had multiple seal sizes, a new high-gap seal design was created to prevent installation errors and the use of incorrect seals. The new seals are pressure activated, which leads to reduced equipment replacement due to wear and tear and enables the user to repair pockets in the field. The traditional assembly process also was altered through the use of a machined rod, which removes the bottom nut on the spool. This simple item has led to many installation errors and resulted in field failures. Another source of field issues was a spring housing that was flooded with seawater, resulting in long-term corrosion. To combat this risk, the spring housing is now flooded with control fluid, leading to improved valve life. Field results already have shown distinct and significant reductions in pressures.

Enhanced condition monitoring

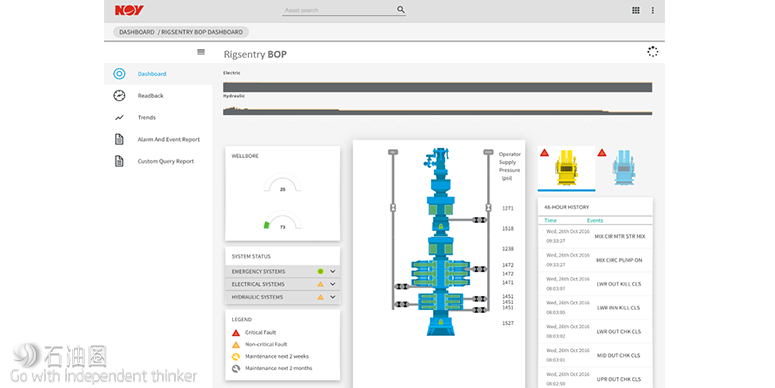

The Rigsentry condition monitoring system is a comprehensive system designed to transmit real-time data to shore, reporting on system status and algorithmically predicting failures rather than reacting to them. The system is in use as part of a BOP monitoring system that focuses on the subsea BOP and its associated controls to reduce the total cost of ownership. Data have long been understood to hold the key to system performance, component improvement and long-term maintenance planning. However, the single largest hurdle in the use of these data has been getting relevant information to shore so the data analysts can act on it. The new system addresses this deficiency by putting real-time, actionable data at the operator’s fingertips via an interactive dashboard (Figure 2).

The level of monitoring is effectively broken down into two service categories. The standard offering provides actionable insight that converts BOP control system data into a secured protocol for transmittal to shore when communications from the rig are possible and buffered for future transmittal when not possible. The system collects and stores data in NOV’s secure cloud-based data platform and can be accessed through a web portal by data scientists, company representatives and third parties as allowed by the customer.

Current system status can be observed using a cell phone, tablet or PC while analog tags, event reports and alarms can be viewed through the live connection. Smart notifications inform relevant rig personnel, including onshore representatives, of maintenance requirements, alarms and system status.

Reports can be configured and periodically run to compare data with historical trends. This has proven valuable to operators in assisting offshore personnel in timely and accurate system repairs. Ultimately, use of the system ensures that a field technician is never without critical issue support from onshore experts.

FIGURE 2. The Rigsentry BOP monitoring system provides critical equipment information in real time to predict failures. (Source: NOV)

The second level of monitoring transforms the initial BOP insight into prediction, affording operators the opportunity to predict failures using prognostic analytics. Multiple models have been created to enable computers and data scientists to mine live data for known deviations from a healthy system that would indicate future failure.

For example, by using the high-pressure supply regulator model, the system conducts an examination of minute pressure changes to identify weak components prior to failure. As they are constantly in use during drilling operations, regulators are often the culprit of BOP failure. Previous solutions were reactive rather than proactive, identifying issues only after operations were already compromised; in normal operation, an offshore technician could identify an issue prior to full failure but nearing failure mode.

The system allows data scientists to mine historical data to identify potential failure modes and assist engineering with product improvements. Prior to the era of Big Data, product improvements were limited to only the most critical failures found offshore and reported back to the original equipment manufacturer.

System stability will continue to improve as more data are received and analyzed. The regulator model— using more than a decade of historical data with 6 billion datapoints—can identify a pending regulator failure several weeks prior to the potentially catastrophic event. Operators using this system can effectively use planned downtime to diagnose and address at-risk components, to streamline between-well maintenance so that rigs can remain active without long periods of downtime, and to prevent unnecessary BOP stack pulls.

Additional predictive models, such as leak detection and operation modes that create risk to the system, are under development.

During a predictive event, a smart notification is sent to those contacts identified by the customer for notification of a potential issue. Engaging the rig crew well in advance of a failure can significantly reduce the risk to operations and personnel. It is critical that the industry works together to continue improving safety, reducing operation costs and embracing digitalization.

石油圈

石油圈