Advancing Downhole Conveyance For Reliability

Smart wireline tools help improve downhole performance with real-time data.

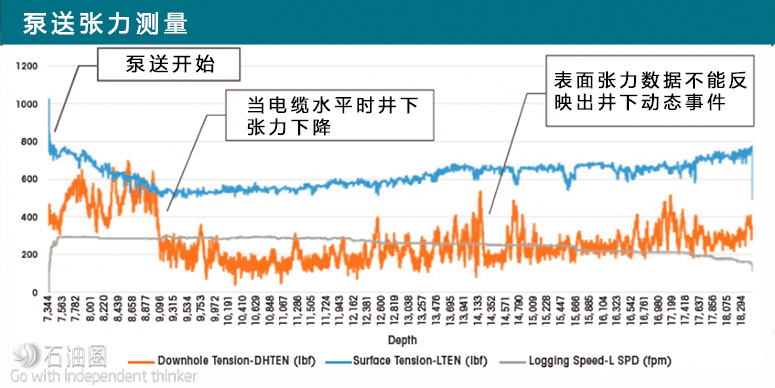

The surface cable tension (blue) does not accurately capture real-time events as compared to the tension measured directly downhole (orange). (Source: Impact Selector International)

Leaders in the downhole conveyance segment of the oil and gas industry are rapidly moving away from a fundamental reactionary mindset to a more studied, proactive approach that incorporates pre-run wellbore modeling for optimum tool string configuration with planning based on the model’s projected frictional forces, impact and sticking force analysis.

These data are used to configure the tool string with a range of conveyance products such as rollers, jars, tension devices, measurement equipment and more. In addition, measurements of the downhole performance of the tool string are used to validate data and assess the planning process.

These customized solutions are designed to successfully deploy downhole tools and most importantly provide assurance of safe, reliable conveyance and accuracy of validation data through measurement. This frontend approach provides operating company personnel with the highest quality data to make key operational decisions throughout the entire life cycle of the well.

One area where effective downhole conveyance is criticalis found in the current U.S. onshore market, which has experienced explosive growth in perforation and pump down applications. In response to this situation, numerous advanced products have been developed to ensure reliable conveyance of tools, gathering of reliable downhole data and providing for validation of the perforation and pump down effort. For example, an integral part of any successful downhole conveyance operation is pre-job planning and tension modeling software. Proprietary modeling software is playing a key role in optimizing tool string design and configuration for successful perforation and pump down operations.

Tools of the trade

Wireline tension monitoring devices maximize efficiency and minimize risk during challenging wireline operations. These measurement devices provide real-time downhole cable tension measurement, eliminating uncertainty and providing the operator with increased control. Maintaining safe cable tension downhole is challenging, particularly in highly deviated and lateral wells, because surface measurements do not account for friction.

If the cable tension is allowed to become too low, then slack cable and released torque can result in cable damage. Correspondingly, if the tension is allowed to become too high during pump down operations, for example, the weak point on the cable can break.

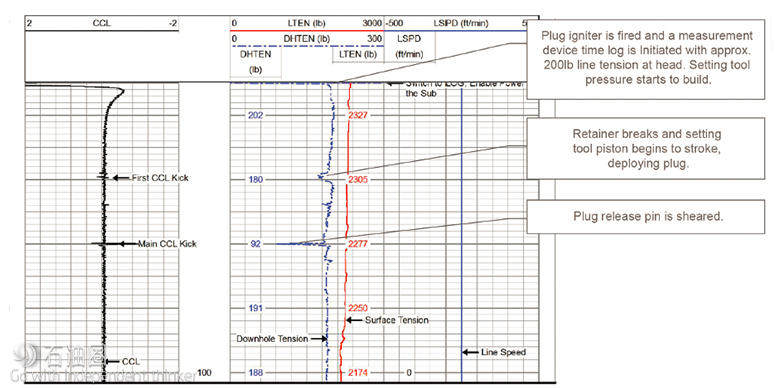

This same ability to measure wireline tension can provide for increased visibility of such downhole events as plug setting and perforating guns firing. These downhole measurements can be particularly valuable when compared to surface tension readings, which often are inconclusive. These new tensioning tools feature a robust design for reliability and are easy to use in the field. Some of these devices also offer plug-and-play compatibility, ensuring that many service companies can use these tools directly with no additional surface equipment required.

The well log confirms successful deployment of the plug. (Source: Impact Selector International)

Recently developed release tools employ a specialized detonator- initiated joint to separate them from a tool string that has become stuck. This specialized joint gives the tool a high tensile rating, allowing it to be utilized anywhere in the string, including below perforating guns and in conjunction with jars. These advanced release tools ensure that the tool string can be retrieved out of the hole each time.

Newly engineered single-time, high-intensity jars are designed to deliver a single jarring force to a perforating string. Engineered to provide a high-intensity jarring force in long horizontals, where cable tension is not available, these jars serve as insurance if a faulty plug-setting tool shear pin needs to be broken or a stuck perforating gun requires a jarring force.

This new style of jar stores energy in a vacuum chamber that is released using a standard detonator. Wellbore fluid pressure accelerates a piston within the jar upward (along with the upper tool string) before hitting a hard stop. The impact of that hard stop shocks the lower tool string upward, providing signifi cant jarring energy. This new style of jar ensures that perforating strings come out of the hole each time.

Rollers are designed to reduce frictional resistance and enable access to high deviations. With a proven track record of success at inclinations up to 87 degrees and at depths in excess of 7,620 m (25,000 ft), rollers can be installed at any point in the tool string. These advanced rollers serve to lift the string off the wellbore and onto highly effi cient rollers, eliminating contact friction and allowing easier and deeper wellbore access.

The roller body rotates around the mandrel, which is connected to the host tool string, providing for a free range of motion. Today’s rollers feature unique body shapes that ensure the rollers are oriented to the low side of the tubing at all times. Rollers also are available in a wide range of sizes and connection profiles allowing them to suit various tool strings and wellbore requirements.

Post-operational analysis

An industry goal is to better validate progress once a job or operation is completed. All parties involved in a downhole operation can validate the progress made using data acquired during the process. This validation completes the feedback loop, which is vital to better understanding the well’s life-cycle program and providing intelligence for future operations.

The long-term goal of this new technology is to be able to deliver reliable conveyance solutions that mitigate risk, enhance effi ciency, reduce cost and improve safety for customers working in the upstream oil and gas industry. For optimum effectiveness, a program of this sort should also be able to access deployment experience and knowledge.

Some of this critical experience and expertise left the industry during the recent downturn, as much of the industry focused on cost reduction, discounts and downsizing. However, some service and E&P companies have invested heavily in technology and developed new conveyance alternatives and best practices that are beginning to defi ne a new future in deployment and conveyance.

石油圈

石油圈