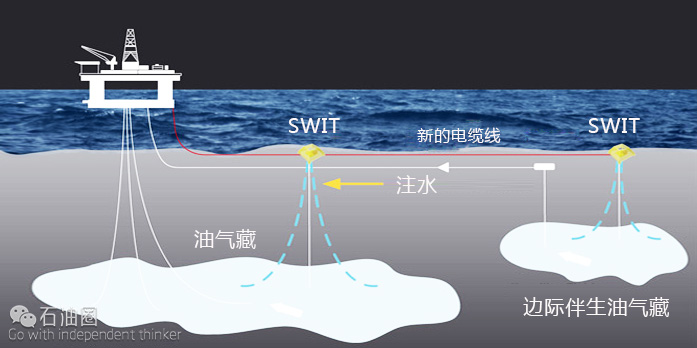

Water injection is the most common way to increase oil production, but traditionally, this has required expensive and bulky topside equipment. With the Seabox™ subsea water treatment unit and SWIT™ Technology, the water treatment is done directly at the seabed and the treated water is pumped straight into the injection well. The SWIT Technology provides the right quality water for water injection where it is needed, when it is needed. This fully flexible approach allows operators to optimize water flooding with the right quality water at any time and location to improve recovery.

Seabox subsea water treatment unit and SWIT Technology is a Norwegian subsea technology, developed during the last 10 years with support and sponsorship from major oil companies. The technology enables treatment of raw seawater directly on the seabed to the desired quality for injection into oil wells for pressure support, sweep and increased oil recovery. The development started in 2003 and embarked on a series of Joint Industry Projects (JIP) backed by the Norwegian Research Council and major oil companies. Through these projects, the Seabox unit and SWIT Technology have been developed and are now ready for real applications.

As a part of National Oilwell Varco’s Subsea Production System, we are uniquely placed to work directly with oil companies, subsea contractors, engineering houses, and industry suppliers to provide the highest level of added value to the overall project. This philosophy ensures that the optimum constellation in any given project is always available to the client.

NOV’s SWIT™ technology lets you rethink subsea water treatment at the source. Treat water directly at the seabed, eliminate the need for topside treatment facilities and get the right quality water for water injection where it’s needed, when it’s needed. Reduce your subsea production costs through simplified infrastructure, advanced water treatment options and injection uptime.

SWIT™ Technology

The SWIT™ technology provides high quality water in areas that are essential for increasing sweep efficiency and avoiding reservoir souring. By creating a total subsea water flood system, increasing IOR possibilities beyond what is achievable by traditional topsides water injection systems, the SWIT™ Technology fills a technology gap.

The Seabox™ unit is our base disinfection and sediment settlement unit. The Seabox™ unit will encompass three different treatment processes. At the intake, the seawater passes through an electro chlorination grid where sodium hypochlorite is mixed into all of the passing seawater. Inside the Seabox™ unit, the seawater will be allowed to react with the chlorine for more than one hour. At the same time, particles larger than 15 micron will be settled out. At the outlet from the Seabox™ unit, a second electro chemical process producing hydroxyl radicals is used for final bacteria kill and to ‘decompose’ biological matters.

The current Seabox™ standard unit will treat 40 000 bpd of seawater and are operated and controlled by our proprietary control system. Other capacity units can easily be designed using our standard components. The unit has no moving parts and only the Treatment Unit of the Seabox™ unit needs to be replaced for maintenance at regular intervals. Typically every 4 years.

The SWIT™ Technology consists of different configurations, where the Seabox™ unit is the cornerstone for providing a fully disinfected water with the bulk part of particles removed. Combined with microfiltration and membranes, we provide completely particle free water, sulphate reduced of sulphate free water and low salinity water. Water qualities can be adapted to the reservoir-specific needs.

Value Creation

The SWIT™ Technology offers new ways of managing reservoirs and assets, to reduce cost and emissions and for IOR and EOR. It puts the reservoir engineer in the driver’s seat, optimizing oil production and recovery based on reservoir insight and opportunities. Not limited by pre-set topside and slot constraints, SWIT™ Technology is an enabler for marginal satellite developments, and for optimizing area developments. The capability to produce any quality water at seabed will enable cost efficient low salinity projects for EOR.

1.Flexibility – Water injection philosophy can be decoupled from topside processes and therefore provide advantageous flexibility in drainage strategy

2.Improved Recovery – Ability to tailor the injection based on reservoir behaviour and the possibility to inject any quality water in otherwise inaccessible areas of the reservoir

3.Reduced CAPEX – Reduced overall investments and increase NPV by deferment of cost . Also reusability options.

4.Reduced OPEX – Lower power consumption, long intervention intervals and reduced offshore manning requirements

5.Higher Regularity – Experienced high regularity, no rotating or moving parts, redundancy built into the system

6.Water Quality – SWIT™ Technology provides superior water quality due to inherent benefits of moving treatment of water to the seabed as the process are not constrained by topsides limitations

The SWIT™ Technology enables a step change in reservoir and asset management that accelerates production and increases recovery on both new developments and mature fields.

Seabox™ subsea water treatment unit

Seabox™ for Matrix Flooding

The Seabox™ subsea water treatment unit can be used in combination with microfiltration to tailor water qualities to suit the reservoir needs and especially to provide particle-free water for matrix flooding. After the Seabox™ unit has disinfected the seawater and settled out major sediment parts, the microfilters can be added to remove all remaining particles. The microfiltration is a ‘dead end’ filter, which will remove all particles down to 0.1 micron.

The microfilters are cleaned with back flushing only and no chemicals necessary. The Seabox™ subsea water treatment unit and microfiltration are controlled by Seabox’s Subsea Control Module (SCM), an ‘All Electric’ solution. This gives a unique control of valve operations and filter performance.

Seabox™ for Tailor-made Water

Membranes are used for sulphate and salt removal. The SWIT™ Technology makes use of two different versions of Membranes:

RO Membranes – for removing salt and implicit also sulphate

Nanofiltration – for sulphate removal

Both membrane types rely on the Seabox™ subsea water treatment unit as well as microfiltration as a pre-treatment to be able to remove sulphate and/or salts continuously without the need for intervention and regeneration of membranes. The process design and general arrangement of components are the same for both RO and Nano.

Seabox™ RO will offer a completely disinfected and particle free water with salinity levels according to a defined specification, typically 500 – 5000 ppm and a total sulphate content less than 2 mg/l.

Seabox Nano will offer a completely disinfected and particle free water with a low total sulphate content, typically less than 40 mg/l.

石油圈

石油圈