哈里伯顿将旋转导向、随钻测井以及StrataSteer 3D服务结合在一起,可实现指哪儿打哪儿,使井段全部保持在油藏“甜点”范围内。

来自丨World oil

编译丨TOM

在墨西哥湾深水区(7000英尺),由于地层横向变化复杂以及地震的不确定性,作业者很难确定着陆段是否接近储层顶部。着陆困难的主要原因是由于地质构造不稳定以及电阻率较低的地层环境。然而对于作业者而言,准确的控制井位与井眼轨迹是极其重要的。若是执行设计失败,就会导致脱靶,造成数百万美元的额外损失。

下面介绍基于地震解释两种不同的地质构造情况,它们会给钻井作业带来额外的挑战:

(1)相对平缓的地层倾角;

(2)更为陡峭的地层倾角。

每种地质情况都需要不同的方法来进行着陆。此外,由于横向变化,邻井之间的测井相关性缺乏必要的随钻测井(LWD)响应,因此难以识别标志层,并且增加了预测地质模型中的不确定性。

业内提出利用地质导向与地层边界绘图系统,控制井眼着陆于目标位置,并利用近钻头系统来辅助降低井眼的狗腿,从而降低着陆的风险与地质不确定性。地层倾角成像系统能够实时提供关键的地层构造信息,因此作业者可以控制井眼着陆,使井段全部保持在“甜点”范围内。

底部钻具组合方案

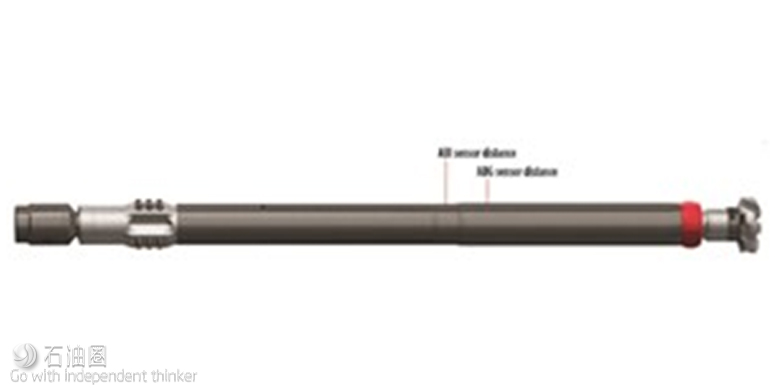

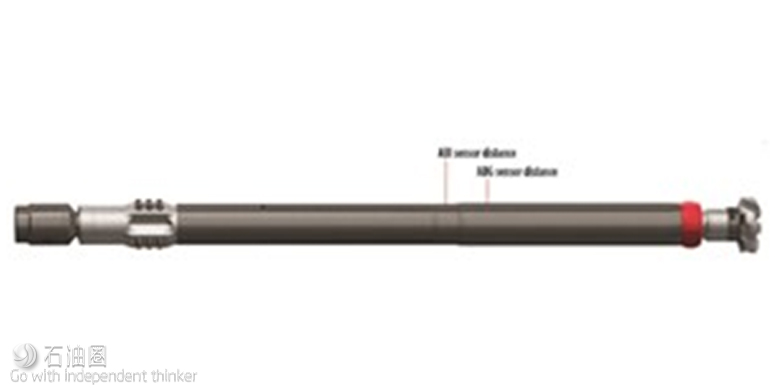

为了解决复杂的定向挑战,哈里伯顿的钻井技术团队推荐了满足要求的底部钻具组合(BHA),以确保按计划实施钻井与测井作业。推荐的钻井方案包括Geo-Pilot 5200旋转导向系统(RSS),近钻头伽马(ABG)、近钻头测斜传感器(ABI)、方位深探测电阻率(ADR)工具以及地层密度和岩性(ALD)传感器,如图1。

图1. 带有Geo-Pilot 5200旋转导向系统与ABI/ABG传感器的底部钻具组合。

数据3D可视化技术。钻井解决方案的核心是StrataSteer 3D动态井眼定位服务,该服务专为小范围靶点而设计,因为该类作业需要复杂的井眼轨迹以及更精确的井眼定位和着陆。该服务将数字3D地球模型、井眼轨迹设计、岩石物理性质与实时随钻测井数据集成到一个灵活的视觉环境中,从而能够根据井眼轨迹变化的情况,快速做出关键的实时决策。该服务为作业者提供了更多的油藏信息,以帮助减少循环时间与钻井作业时间,同时提高油藏的接触面积。

钻井作业

钻井作业时,将传感器获得的数据通过StrataSteer三维地球模型软件进行正向建模处理,以预测油藏的顶部进入点。但由于缺乏邻井测井的相关性分析,这种处理会造成地质构造的不确定性。但是,利用新的实时数据过滤已有信息,工程师可以将这些信息与选定的邻井关联起来,从而了解地层情况,以实现相对于油藏的精确井眼定位。

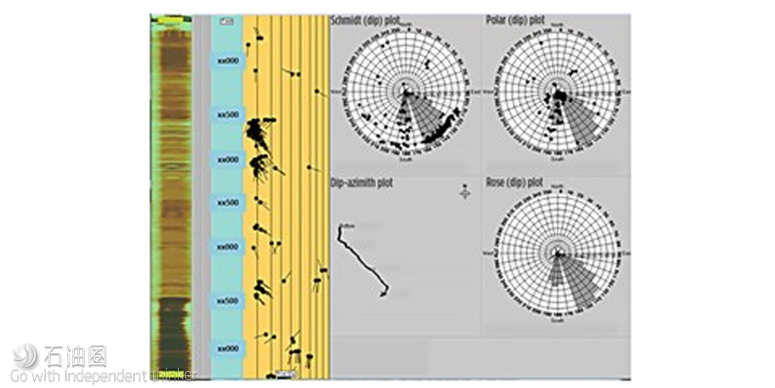

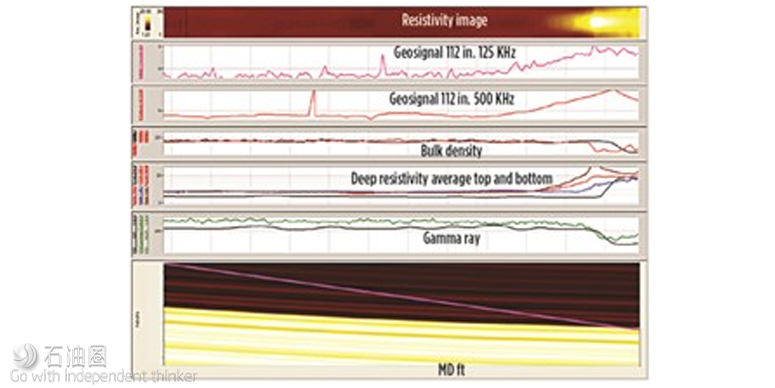

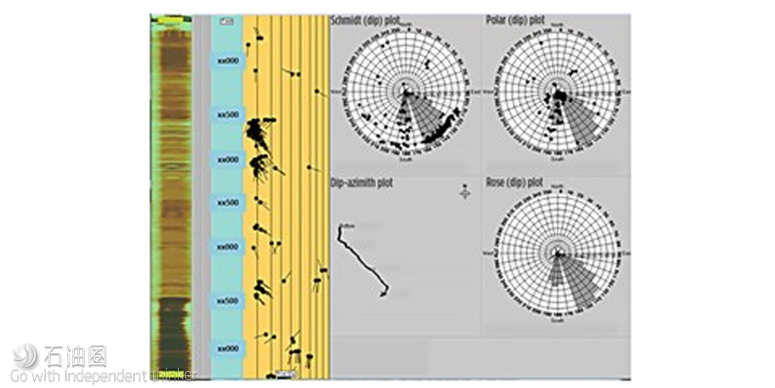

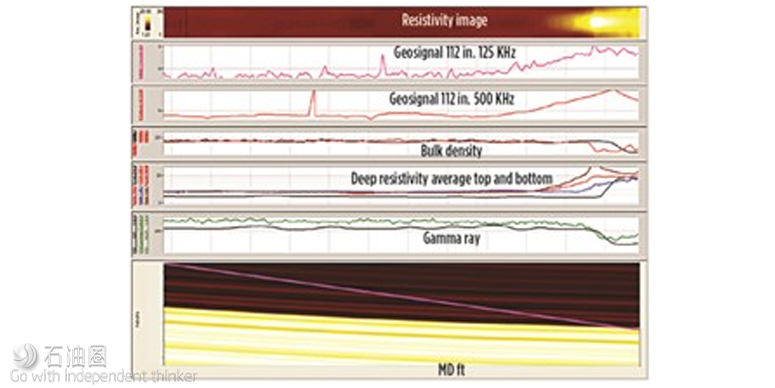

当井段着陆时,近钻头伽马传感器提供了近钻头方位伽马值,能够及时显示出岩性的变化,并确保主动导向以避免不必要的井眼弯曲。地层密度与岩性传感器提供了地层倾角与地层构造数据,这些数据被整合到StrataSteer 3D地球模型中,如图2。储层顶部的实时投影在整个着陆过程中提供了出色的控制。方位深探测电阻率传感器的数据证实了井眼着陆位置存在碳氢化合物,如图3.

图2. ALD图像解释与产生的地层倾角图。

图3. 井下传感器组合辅助井眼着陆。

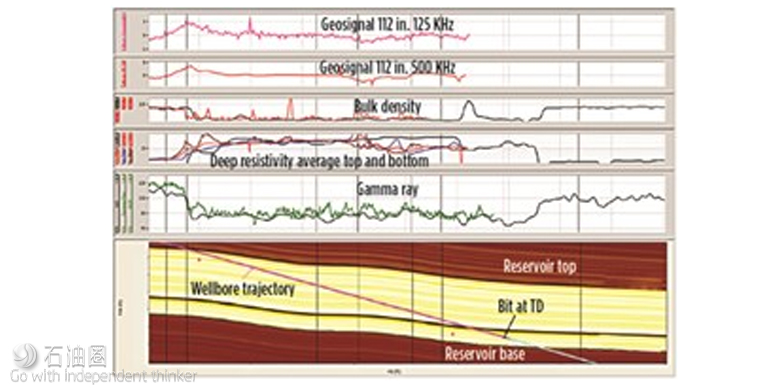

利用相同的工具,继续钻进至别的靶点。由于油藏内的电阻率较高,ADR传感器最适合为周围地层边界提供足够的预警。ABG与ALD数据分别提供了近钻头的地层与构造信息,为StrataSteer三维软件的地质模型提供了补充。这一工程钻井解决方案使井眼处于最佳位置,使作业者能够充分开发储层,增加产量。

最优开发油藏

该团队与作业者合作,确定了储层的挑战,并设计了一套地质导向解决方案,以最大限度地提高深水油藏的价值。该解决方案主要包括对邻井数据的全面分析,以及各种井下传感器技术的正向建模。最终,工程团队确定了一个集成随钻测量、随钻测井、旋转导向的组合,可以有效地实现作业者的两个主要钻井目标:增加产量、降低成本。

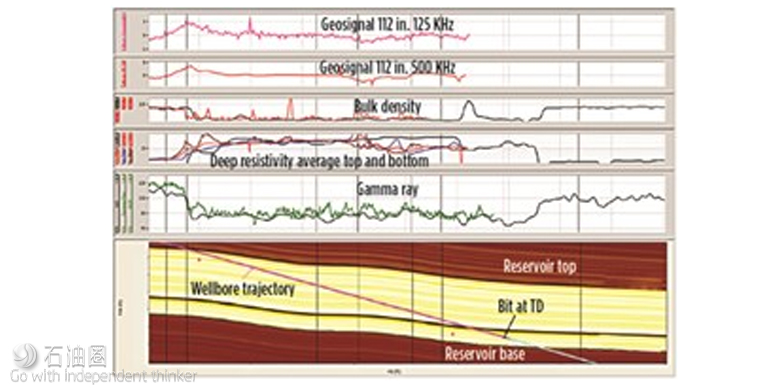

图4. 着陆后,相同的传感器使工程师能够精确的控制油藏中的水平段。

作业成功。在作业过程中,近钻头伽马值可以显示出地质的变化,因此能够准确快速的判断出储层顶部,优化进入点,使钻井团队能够成功地将井眼导向至目标区域。并利用测井数据,不断更新地质构造模型,以准确确定地层倾角与岩性,加强对储层的理解,从而提高钻井效率。地质导向解决方案使井队能控制井眼全部位于产油层,最终止于在油水界面之上(图4)。除了增加产量外,地质导向解决方案为作业者节省了大约60万美元, 并帮助其最大化开发深水油藏。

您也有让人挠头的难题需要解决,或是优质技术想要找应用市场吗?如果有的话,欢迎联系小编微信或邮箱,也许能找到一剂良药。

二丫:131-3255-0596;zhanglingyu@cnoocraiborn.com

大安:131-3203-1392;lishian@cnoocraiborn.com

For English, Please click here (展开/收缩)

At a deepwater (7,000 ft) location in the Gulf of Mexico, an operator was struggling to identify the approaching reservoir top during the landing section due to complex geology with lateral variation and seismic uncertainty.

At a deepwater (7,000 ft) location in the Gulf of Mexico, an operator was struggling to identify the approaching reservoir top during the landing section due to complex geology with lateral variation and seismic uncertainty. The primary challenges for landing the curve included structural instability and a low-resistivity environment. Precise wellbore placement and correct borehole trajectory were critical. Any failure to execute per plan would cause a geological sidetrack, costing millions of dollars in extra rig time.

Two different structural scenarios, based on seismic interpretation, provided additional challenges: 1) a relatively gentle dip angle; or 2) a steeper dip angle on the landing approach. Each geological scenario required a different method to land the wellbore. Additionally, log correlation with offset wells lacked the required logging-while-drilling (LWD) responses, due to lateral variances, making it difficult to identify marker beds and increased uncertainty in the models used to predict geology.

To reduce risk and geological uncertainty in landing the borehole, proactive geosteering along with a bed boundary mapper system were proposed to accurately land the wellbore at the desired position coupled with at-bit systems that would assist in minimizing wellbore tortuosity. A formation dip imaging system would provide critical formation structure in real-time enabling the asset team to control the landing and maintain the lateral wellbore section 100% in the sweet spot.

ENGINEERED BHA SOLUTION

To solve the complex set of directional challenges, Halliburton’s technical drilling team recommended a bottom-hole-assembly (BHA) that met the requirements to ensure the wellbore was drilled and logged per plan. The proposed drilling solution included a Geo-Pilot 5200 rotary steerable system (RSS) with at-bit gamma (ABG) and at-bit inclination sensors (ABI), combined with an azimuthal deep resistivity tool (ADR) and azimuthal lithodensity (ALD) sensors.

3D data visualization technology. Central to the drilling solution was the StrataSteer 3D dynamic wellbore positioning service, which is designed specifically for smaller targets that require complex well paths and more accurate wellbore positioning and landing. The service integrates digital 3D earth models, planned well trajectories, petrophysical input and real-time LWD data into a flexible visual environment that enables the rapid interpretation required to make critical real-time decisions regarding borehole trajectory changes. The service provides operators with greater reservoir insight to help reduce both planning cycle-time and drilling hours, while enhancing reservoir understanding for maximum contact.

WELL EXECUTION

During drilling operations, data captured from the sensors was processed through the forward modeling functionality of the StrataSteer 3D earth model software, to predict the top entry point in the reservoir. The project was hampered by the lack of log correlation between offset wells, which caused uncertainty in geological scenarios. However, by filtering existing information with new real-time data, it enabled engineers to correlate this information with select offset wells leading to understanding of the geological scenarios, enabling accurate wellbore positioning, relative to the reservoir.

When landing the section, the ABG sensor provided near-bit azimuthal gamma ray readings, showing changes in lithology immediately and ensuring proactive geosteering to avoid unnecessary borehole tortuosity. The ALD delivered dip angles and structural data, which were incorporated into the StrataSteer 3D earth model. The real-time projection of the reservoir top provided excellent control throughout the landing process. The ADR readings confirmed the presence of hydrocarbons for the wellbore landing.

Drilling continued in the lateral section, utilizing the same tools, but with different objectives. Because of higher resistivity within the reservoir, the ADR sensor was best-suited to provide sufficient warning for the surrounding formation boundaries. The ABG and ALD data provided the near-bit formation and structural information respectively that complemented the geological model in StrataSteer 3D software. This engineered drilling solution kept the wellbore in the sweet spot, enabling the operator to fully exploit the pay-zone for increased production.

MAXIMIZING ASSET VALUE

The team collaborated with the operator to identify the reservoir challenges and engineer a geosteering solution to maximize the value of the deepwater asset. The solution-based design(s) included a thorough analysis of offset data, along with forward modeling of various down-hole sensor technologies. After the study, the engineering team determined an integrated MWD/LWD/RSS combination had the potential to efficiently achieve the operator’s two main drilling objectives—increase production and lower costs.

span>Operational success. During the run, at-bit ABG readings showed variations in geology, enabling accurate and quick detection of the formation top, optimizing the entry point and enabling the drilling team to successfully land the wellbore in the target zone. The model was updated continuously to accurately determine formation dip and lithology, increasing drilling efficiency through enhanced reservoir understanding. The geosteering solutions enabled the drilling team to keep the lateral in the target pay-zone 100% of the time, stopping above the oil water contact, Fig. 4. In addition to increasing production, the engineered geosteering solution saved the operator approximately $600,000, aiding in maximizing the value of this deepwater asset.

未经允许,不得转载本站任何文章:

石油圈

石油圈