The BLITZ coiled tubing (CT) frac sleeve system delivers targeted stimulation treatments to a nearly unlimited number of stages with efficiency and ease, helping customers to control costs and improve production potential in unconventional wells. With a rugged, resettable BLITZ annular packer, positive location capabilities, and single-shift and multishift frac sleeve options, the system represents a new level of flexibility and reliability for CT fracturing operations.

Although CT sleeve systems are gaining popularity due to their large stage count potential, targeted treatments, and operational efficiency, most systems cannot accurately locate sleeves once they are installed downhole, prolonging operations and driving up costs. This is because these systems rely on depth correlation, which is imprecise and often requires excessive repositioning of the bottomhole assembly (BHA) to find the casing collar, and subsequently engage and shift sleeves. This pulling and pushing through the casing not only increases coil cycling and nonproductive time (NPT), it quickly compounds the time it takes to move from stage to stage—driving up overall job time.

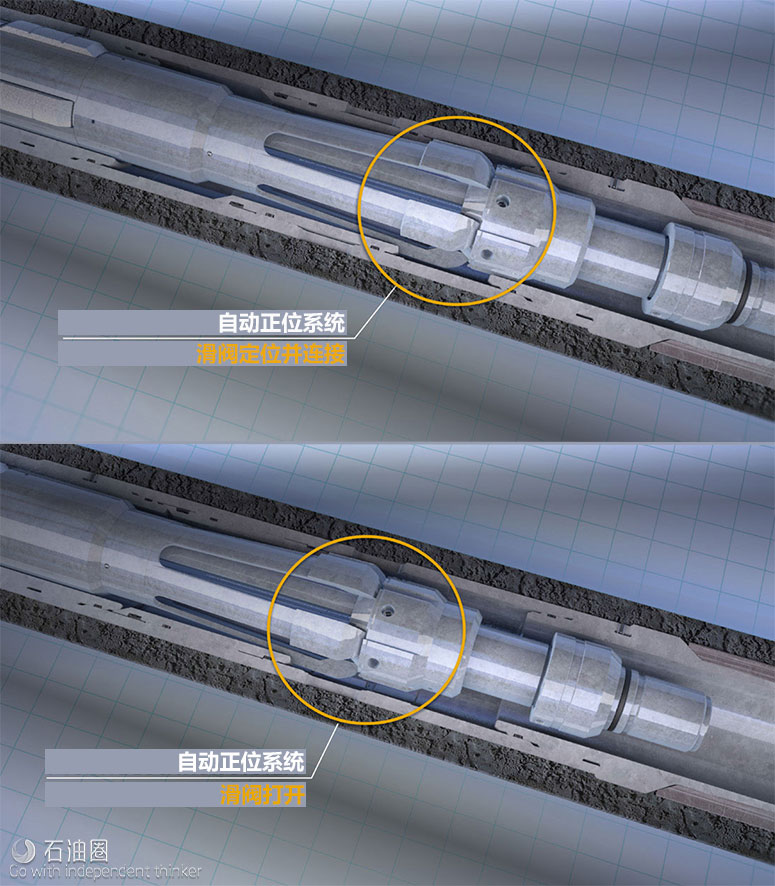

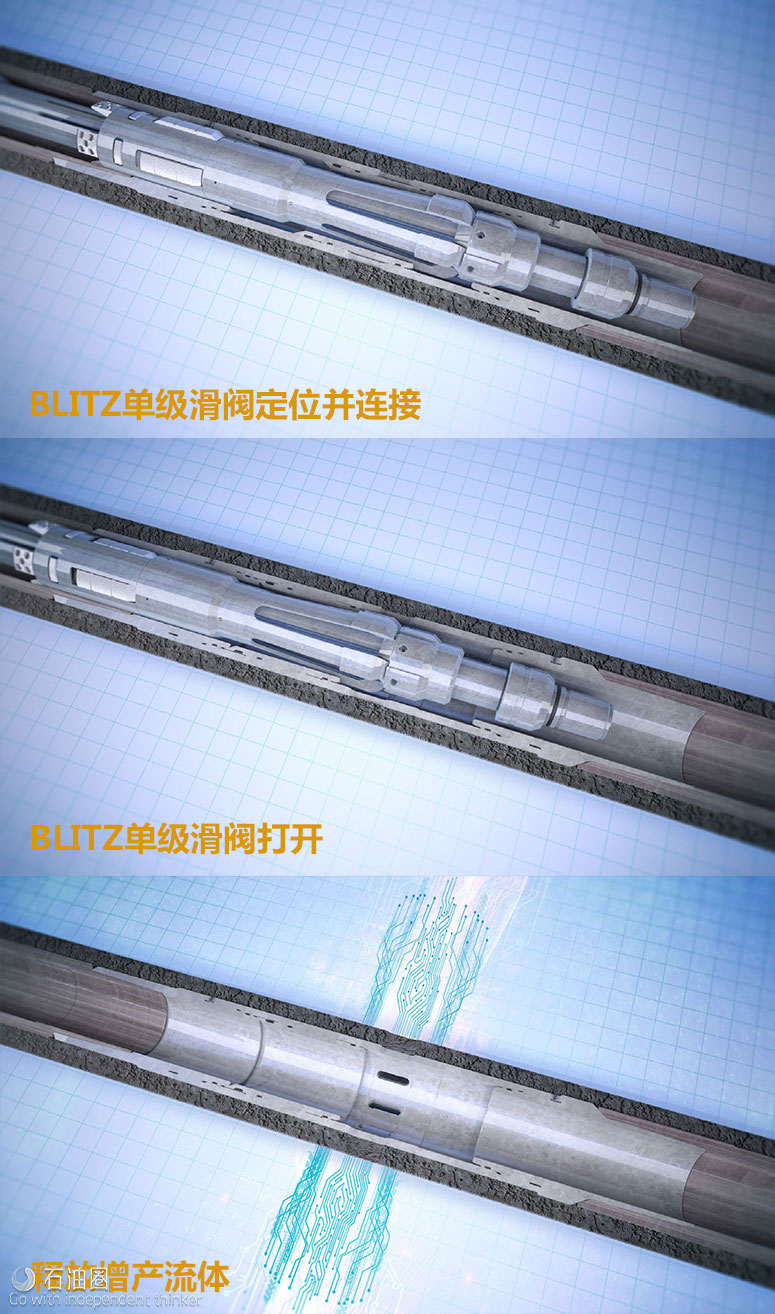

Unlike any other CT fracturing system, the BLITZ packer BHA includes a collet-locating system that provides a positive weight indication when each sleeve has been engaged, as well as when it has been shifted. This ensures proper BHA spacing and depth throughout operations, enabling rapid, uninterrupted fracturing from toe to heel.

Both the single-shift and multishift frac sleeves are mechanically operated and can be shifted using either the BLITZ packer BHA or an HB-3 shifting tool. The BLITZ multishift frac sleeve offers added operational flexibility because it can be opened and closed an unlimited number of times. This feature enables operations such as:

1. Closing sleeves to shut off nonproductive stages

2. Opening sleeves to restimulate selected stages

3. Closing sleeves after fracturing to allow the formation to heal and reopening them at a later date.

After the BLITZ frac sleeves have been installed, the BLITZ packer BHA is run in hole to actuate sleeves and to isolate stages. Because the packer BHA can withstand annular flow rates up to 70 ft3/min (2 m3/min), it is ideal for extended-reach applications where tools may need to be pumped down to bottom.

Once the packer locates and shifts a sleeve to the open position, it moves below the frac ports and sets via a small compressive force to isolate the stage. The stimulation treatment is delivered, and the packer is released and moved uphole to the next sleeve, and the process is repeated.

A circulation sub with customized flow nozzles is positioned directly above the packer to circulate out any sand that settles on or around the BHA, helping to ensure reliable packer release. The circulation sub also enables real-time bottomhole pressure monitoring so treatments can be adjusted on the fly and premature screenouts can be avoided. If a screenout does occur, the sand can be circulated out by simply pumping down through the CT, significantly reducing NPT. If perforations need to be added after sleeves have been installed, the circulation sub can perform sand jetting to establish additional reservoir communication points along the well for increased access.

In addition to delivering real-time pressure data, the BLITZ system BHA can also collect pressure and temperature data during treatments. This information allows customers to conduct post-treatment analyses on stimulation effectiveness to help optimize future jobs, and to evaluate restimulation potential.

Because the BLITZ frac sleeves have no inside diameter (ID) restrictions, no post-stimulation milling is required for production to begin. This also helps to simplify future access.

Case Study

A customer operating in the Clearwater area of Alberta, Canada was preparing to complete an extended-reach well in the Cardium formation. With a lateral length of 9,925 ft (3,025 m), the well offered considerable reservoir access, and would require a multistage completion solution that could deliver the right balance of reliability and reservoir contact. Additionally, the customer wanted to keep costs low, and needed the solution to be economical, without sacrificing performance.

Based on these requirements, Baker Hughes, a GE company (BHGE), recommended the BLITZ? coiled tubing (CT) frac sleeve system. Comprised of a new generation sleeve design and a rugged, resettable BLITZ annular frac packer, the system is more robust and reliable than other CT systems, and enables treatment of nearly an unlimited number of stages. These benefits would be key in completing the almost 10,000-ft (3,048-m) lateral which had four known doglegs with severity greater than 10°/100 ft (10°/30 m).

The completion design called for a BLITZ single-shift CT sleeve to be installed every two joints of casing, for a total of 134 sleeves across the lateral section. Once the sleeves were installed and cemented into place, the BLITZ packer bottomhole assembly (BHA)—which included a disconnect, blast joints, aperforator with a customized nozzle flow area, and pressure/temperature gauges—was run to the toe of the well without issue. Because the packer BHA can withstand annular flow rates up to 70 ft3/min (2 m3/min), it is ideal for extended-reach applications where tools may need to be pumped down to bottom.

During fracturing operations, the packer was moved from one sleeve to the next with efficiency and ease. Unlike any other CT fracturing solution, the BLITZ packer BHA includes a collet locating system that provides a positive weight indication when each sleeve has been engaged, as well as when it has been shifted. This allowed the BHGE team to manipulate the downhole the tools with precision, ensuring proper BHA spacing and depth throughout operations. In the toe section, the sleeve-to-sleeve move time averaged 9.5 minutes, and shortened to 6.5 minutes towards the heel, with the fastest move time clocked at only 4.5 minutes.

The aggressive pump program presented no challenge for the BLITZ packer BHA, which reliably withstood pressures exceeding 10,000 psi (689 bar) throughout treatment operations. Approximately 38,000 lb (17,237 kg) of sand was pumped per stage, with several stages reaching up to 51,500 lb (23,360 kg) of sand, and at pump rates up to 215 ft3/min (6.1 m3/min).

During a sudden, hard screenout, the annular pressure reached nearly 12,500 psi (862 bar). The customized nozzles positioned directly above the packer quickly circulated all of the sand out of the annulus and away from the BHA, enabling instant screenout recovery. The packer easily released after five such events during this job, allowing operations to proceed quickly and as planned. The BLITZ packer BHA successfully located, shifted, and isolated 101 of the 134 frac sleeves in one downhole trip, demonstrating its robustness. Another BLITZ packer BHA was run to shift the remaining sleeves.

Due to the reliability and efficiency of the BLITZ system, the total job time was only 151.5 hours with no recorded nonproductive time (NPT) associated with sleeve location and actuation. Pleased with the system’s performance and overall economics, the customer plans to continue using it in future applications.

To-date, the customer has completed a total of 11 wells [10,236 ft (3120 m) average lateral length] with the BLITZ CT system, and has experienced zero operational issues or NPT associated with locating and actuating 1,000+ sleeves—137 of which were in a single well.

石油圈

石油圈