斯伦贝谢新创插入式射孔枪系统,能实时井下测量、监控和确认作业过程,降低作业风险,提高作业效率。

来自 | E&P

编译 | 白小明

斯伦贝谢近期推出Tempo带测量仪的对接式射孔枪系统,是业内首款完全集成了创新设计的插入式射孔枪系统,它大大简化了组装、装枪和射孔流程,具备先进的实时井下测量功能来监控和确认作业过程,从而降低了作业风险,增加了安全性、可靠性和效率。

专利化的对接组件是Tempo射孔枪系统插入式设计的关键元素。它简化了设备组装流程并消除了造成未按设计执行射孔的一些因素:如技术性较强的压接和接线失误。射孔枪设计进一步简化,密封件更少,长度更短,从而最大限度地提高了可用的枪串长度。与传统系统相比,无论是单枪还是选择性多枪,都只需极短的时间进行线下装枪,从而进一步提高了安全性和作业效率。

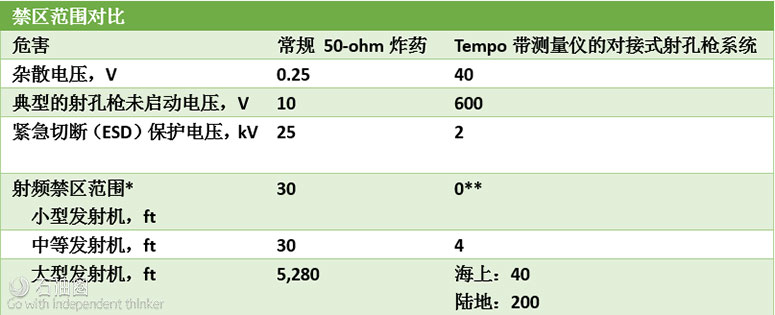

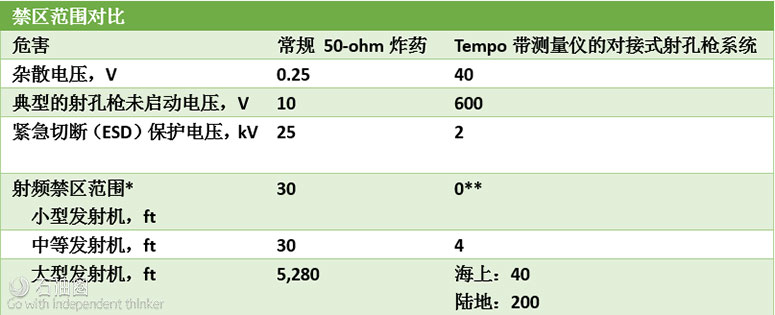

凭借其工程控制和集成的测量功能,Tempo射孔枪系统符合API RP 67第2组规范的最高安全级别,射频保护功能得到第三方独立机构(ITPO)的验证。在几乎所有的使用情况下,都不用考虑射频危害问题。

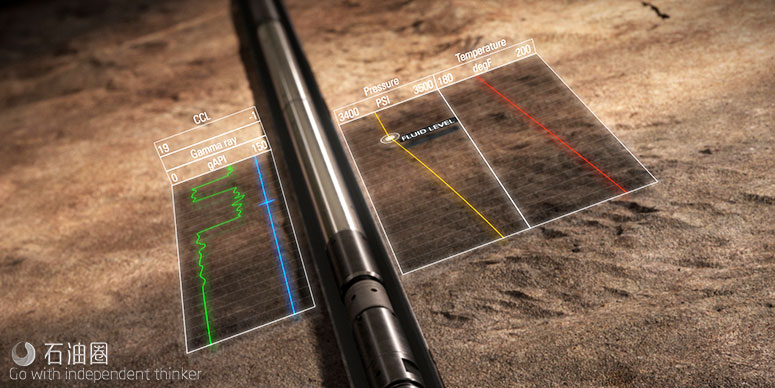

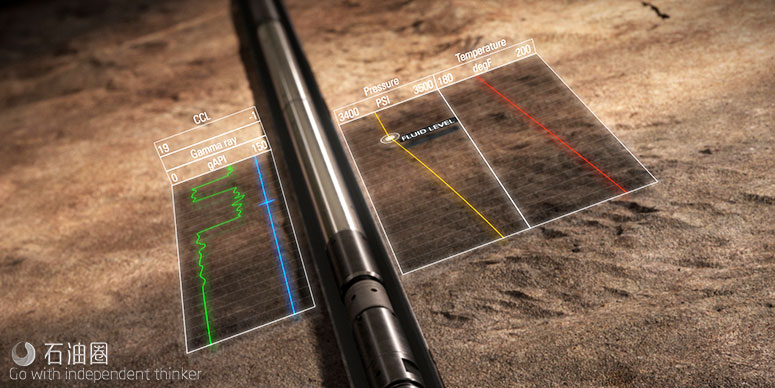

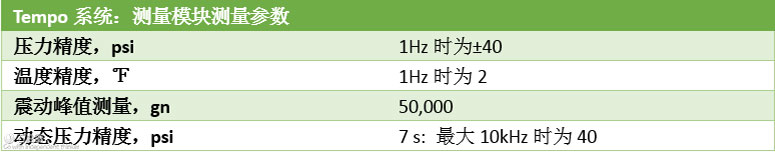

另外,通过引入先进的射孔测量功能,Tempo射孔枪系统可提供一整套实时、同时采集的数据,这对验证和优化射孔设计和执行至关重要。强化的测量技术可以在射孔前、射孔过程中和射孔后获得压力、温度、CCL以及伽马射线(可选)数据,无需在紧凑的设计中添加减震器。

对于PURE *清洁射孔系统、P3 *射孔后处理以及火药的处理,Tempo系统测量动态压力,并在射孔后数秒内传输数据。Tempo系统还准确记录震动峰值,以帮助验证射孔枪震动建模并优化以后的操作。

应用

(1)采用中空传输工具的射孔枪系统

(2)单枪或选择性多枪应用,单次入井最多可携带40枪

(3)整个射孔期间进行测量

(4)确保射孔期间动态欠平衡和震动峰值

优点

(1)射频(RF)安全级别满足API RP 67第2组规范,这意味着在大多数使用情况下,井场射孔作业可连续不中断进行

(2)可提前配置射频安全功能,提高作业效率并节省钻机时间

(3)简化的系统设计大大减少了组装过程中出现人为失误的可能性,从而提高可靠性并避免射孔枪未按设计执行操作

(4)与传统的射孔枪系统相比,大大缩短了单枪和选择性多枪的装枪时间

(5)单支射孔枪长度更短,从而可组装更长的枪串

(6)可以在地面和入井时彻底检查系统的完整性

(7)在标准和铬制套管中,通过关联伽玛射线和套管接箍定位器(CCL)的位置数据,确保精确的深度控制,套管最大直径可达95/8-in

(8)快速、准确的压力测量,确保动态欠平衡,保证射孔的清洁性

特点

(1)兼容深穿透和大井眼射孔弹

(2)兼容PURE清洁射孔系统和P3射孔后处理

(3)坚固耐用的传感器和电子组件可承受反复的射孔枪震动

(4)有效的CCL测量数据

(5)电缆、泵送、E-连续油管或爬行器传输

(6)最高应用温度达340℉

*小型发射机(手持无线电、蜂窝电话、蓝牙、wifi,驾驶监控器等):≤5W。中型发射机(卡车和船用无线电):>5且<200 W。大型发射机(电视和无线电发射塔,海上雷达系统):≥200 W。

**尽管没有射频危害,但考虑到锂电池的火灾危害,建议不要在紧靠射孔枪的位置安装任何带有锂电池的组件。

实用案例

Bapetco利用插入式Tempo射孔枪系统简化射孔作业

挑战:提高深井多层射孔作业的效率。

解决方案:部署Tempo带测量仪的对接射孔枪系统,它采用集成测量功能并增强了安全和效率的插入式设计。

结果:通过比之前节约一半多的装枪时间,并较早进行系统完整性井下确认,大幅节约了作业时间。

Badr El Din石油公司(Bapetco)是壳牌埃及石油公司与埃及通用石油公司共同组建的一家合资企业,其想要提高西部沙漠深井多层射孔作业的效率。无论使用传统的单枪还是选择性多枪系统,组装设备和装枪都需要很长的操作时间,并且在将系统传输到位前无法验证系统的完整性。在这些深井中,任何在将系统传输就位前无法诊断出来的连接失误,由于需要将系统起出地面进行维修,都会造成漫长的作业等停时间。Bapetco也非常担心起枪出井时可能对人员造成的危害。

斯伦贝谢推荐使用全新的Tempo带测量仪的对接射孔枪系统来简化部署并提高操作安全性。这种紧凑型射孔枪系统最多能够携带40枪进行选择性射孔,以有效射穿多个储层,系统在单次入井中实现了爆炸物有效载荷的最大化。插入式设计简化了装枪过程,通过消除传统射孔枪系统所需的现场压接和接线问题,提高了安全性和可靠性。在连接到有线电缆头和入井前,操作人员在地面可采用在线诊断来检查Tempo系统的完整性。在将射孔枪下入到地面以下至少200英尺后,就可以进行确认检查,而无需等到将射孔枪下入到目标射孔深度。

您也有让人挠头的难题需要解决,或是优质技术想要找应用市场吗?如果有的话,欢迎联系小编微信或邮箱,也许能找到一剂良药。

二丫:131-3255-0596;zhanglingyu@cnoocraiborn.com

大安:131-3203-1392;lishian@cnoocraiborn.com

For English, Please click here (展开/收缩)

Plug-in system efficiency paired with full-visibility perforating

The Tempo* instrumented docking perforating gun system is the industry’s first perforating gun system to fully integrate an innovatively designed plug-in gun that significantly simplifies assembly, arming, and firing with real-time advanced downhole measurements for monitoring and confirming operations to mitigate risk while increasing safety, reliability, and efficiency.

New gun design for improved perforating outcomes

Proprietary docking components are the key element of the Tempo gun system’s plug-in design. They simplify assembly and eliminate the major causes of perforating misfires: technique-sensitive crimping and wiring. Gun design is further streamlined with fewer seals and reduced lengths, which in turn maximizes the usable gun string length that can be deployed.

Both single and selective guns can be armed offline in significantly less time than required for conventional systems to further improve safety and operational efficiency.

With its engineered controls and integrated measurement capabilities, the Tempo gun system provides the highest level of safety in compliance with API RP 67 Group 2 specifications, with RF protection verified by an independent third-party organization (ITPO). RF silence requirements are eliminated in almost all use cases.

Integrated measurements for real-time insight

By incorporating advanced perforating measurements capability, the Tempo gun system delivers a complete suite of real-time, simultaneously acquired data that are critical for verifying and optimizing perforating design and execution. The ruggedized measurement technology obtains pressure, temperature, CCL, and optional gamma ray before, during, and after perforating without the need for a shock absorber in the compact design.

For PURE* clean perforations system, P3* post-perforating treatment, and propellant treatments, the Tempo system measures the dynamic pressure and transmits the data within seconds after firing. The Tempo system also accurately records peak shock to help validate gun shock modeling and optimize future operations.

APPLICATIONS

■ Hollow carrier perforating gun systems

■ Single or selective perforating applications with up to 40 guns in a single descent

■ Advanced measurements throughout perforating

■ Confirmation of dynamic underbalance and peak shock while perforating

BENEFITS

■ Radio frequency (RF) safe per API RP 67 Group 2 specifications means that wellsite operations can continue uninterrupted during perforating operations in most use cases

■ RF-safe capability enables arming in advance to improve operational efficiency and save rig time

■ Simplified system design significantly minimizes the potential for human error during assembly to increase reliability and eliminate perforating misfires

■ Gun arming time for single and selective guns is greatly reduced in comparison with conventional gun systems

■ Shorter gun lengths support deploying extreme-length gun strings

■ Integrity of the system can be fully checked at surface and while running in hole

■ Precise depth control is ensured by correlation using both gamma ray and casing collar locator (CCL) in standard and chrome tubulars for diameters up to 95/8 in

■ Fast, accurate pressure measurement verifies the dynamic underbalance for delivering clean perforations

FEATURES

■ Compatible with both deep penetrating and big hole shaped charges

■ Compatible with PURE clean perforations system and P3 post-perforating treatment

■ Ruggedized sensor and electronics package to withstand repeated gun shock

■ Powered CCL measurement

■ Wireline, pumpdown, e-coil, or tractor conveyance

■ Applications up to 340 degF

Case Study

Engineered docking design cuts arming time by more than half and increases operational safety, reliability, and efficiency

Challenge: Improve the efficiency of multizone perforating operations in deep wells.

Solution: Deploy Tempo instrumented docking perforating gun system, which features a safety- and efficiency-enhancing plug-in design with integrated measurements capability.

Result: Saved significant operational time by arming perforating guns in less than half the previously required time and conducting early downhole verification of system integrity.

Perforating challenges in completing deep wells

Badr El Din Petroleum Company (Bapetco), a joint venture between Shell Egypt and the Egyptian General Petroleum Corporation, wanted to improve the efficiency of multizone perforating operations in deep wells in the Western Desert. Whether single or selective conventional perforating gun systems were used, significant operational time was required to assemble and arm the guns, and the integrity of the system could not always be verified until it was conveyed to perforating depth. In these deep land wells, any connection failures that could not be diagnosed until the gun was at depth caused lengthy operational downtime by requiring return to surface to be remedied. The risks posed to personnel in retrieving the live guns were also a major concern for Bapetco.

Innovative perforating system design for increased safety, reliability, and efficiency

Schlumberger recommended using the new Tempo instrumented docking perforating gun system to streamline deployment and support operational safety. This compact gun system enables running up to 40 guns for selective initiation to efficiently perforate multiple reservoir zones with a maximized explosives payload in a single trip in the well. The plug-in design simplifies the arming process to increase safety and reliability by eliminating the variability introduced by the wellsite crimping and wiring required for conventional gun systems. Onboard diagnostics are used to check Tempo system’s integrity at surface, before connecting to the wireline cable head and running in hole. A confirmation check can then be conducted once the guns are at least 200 ft below ground level, instead of requiring the guns to be at the target perforating depth.

未经允许,不得转载本站任何文章:

石油圈

石油圈