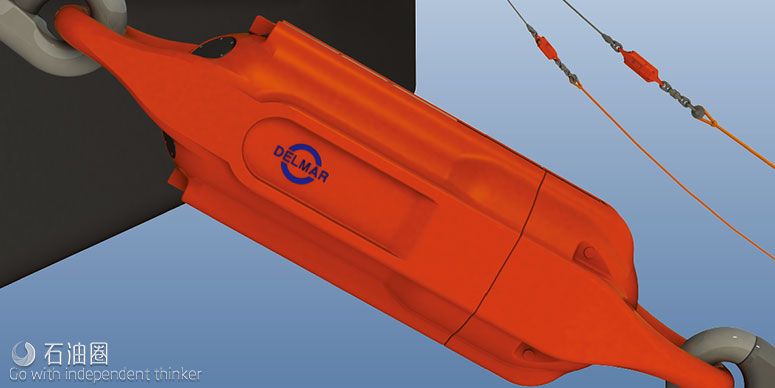

RAR Plus™ Next Generation Mooring Release Technology

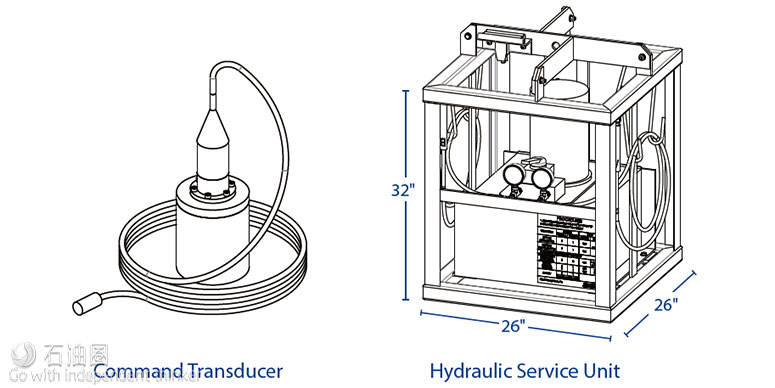

The next generation of Rig Anchor Release (RAR), the RAR Plus, builds on a 35-year history of proven acoustic release technology by adding several key features, including a mechanical backup release method. The new backup method ensures the ability to release the moorings in the unlikely event that the remote acoustic transmission fails to actuate the RAR. The mechanical backup release bypasses the acoustic, electronic, and hydraulic systems in the RAR Plus, and it can be actuated by either the rig itself or with a nearby support vessel.

The RAR Plus minimum break load (MBL) has been increased to accommodate modern R5 high-strength mooring lines. The increased repeatable release load limit allows for disconnection at extreme line tensions.

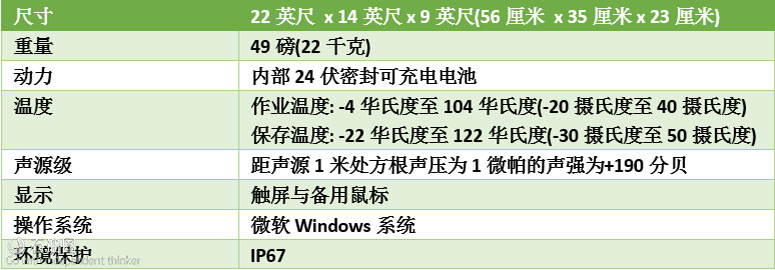

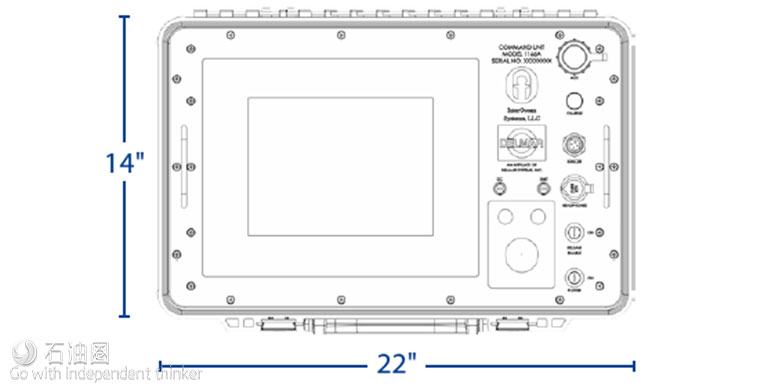

The RAR Plus internal components both directly measure and indirectly calculate line tensions in real time for display on board the rig in a userfriendly graphical user interface. This interface displays valuable data for use during mooring activities and for the duration of the drilling campaign. The data stream can also be input into 3D catenary monitoring systems, providing ultimate risk mitigation for mooring in congested fields. All data is saved in both the topside processing unit and locally within the RAR Plus memory for postanalytical purposes. The telemetry system is optional and can be easily removed for applications that do not require enhanced mitigation measures.

RAR Plus Advantages

• Proven and Reliable Acoustic Release Design

• Surface Controlled Selective Quick Disconnect for Drillships and Semis

• Allows Rigs to Quickly Evade Storms, Ice Floes, or Well Emergencies

• Provides for Maximum Rig Move Efficiency

• Mechanical Backup Release for Ultimate Reliability

• High Ultimate Load and Release Load Capability

• Remote Direct and Indirect Line Tension Monitoring System

• ABS and DNV Certified Mooring Component

Ultimate Reliability

• High release load rating for acoustically activated disconnection at extreme tensions

• Redundancy in key acoustic and hydraulic functions

• Mechanical backup release method can be actuated by either the rig or a nearby support vessel

Real-Time Monitoring

• Continuous monitoring of directly measured and indirectly calculated line tensions

• Independent of the rig’s existing load cell tension readings

• Real-time and historical data easily viewable with user-friendly graphical user interface on board the rig

Quality Construction and Design

• ABS and DNV certified

• Internal components are double-sealed in independent pressure housings

• Over 35 years of proven success

• Long battery life (18 months)

• MBL exceeds that of 84 mm R5 chain

• Proprietary, durable locking system designed for repeated release

石油圈

石油圈