OTC, which will take place 2-5 May in Houston, announced that 13 technologies will receive the 2016 Spotlight on New Technology Award. OneSubsea is honored to have the HyFleX™ Subsea Tree System named a finalist in the 2016 SPE Offshore Achievement Awards’ Emerging Technology Award category.

The major challenges faced by the subsea industry in the current climate

Mike Garding, Chief Executive Officer for OneSubsea, gave a keynote address at UTC last year. He said: “The subsea industry is multi-faceted and highly technical, and as the industry moves towards increasingly complex environments, both operators and technology suppliers must dedicate more and more resources to overcome new and changing technical and environmental challenges. These include well access, flow assurance, and improving recovery from environments with high temperatures and pressures. When the market is down, operators and technology suppliers must re-evaluate how they approach these challenges. ”

Operators need solutions that are exceptionally cost-effective without sacrificing quality and reliability—and that increase their return on investment.

Mike Garding said: “Suppliers must facilitate identification of solutions that not only maintain cost control and reliability, but have the capability to greatly enhance the value that these subsea fields can deliver. At OneSubsea, we’re driving innovation to deliver technical solutions that are both cost-effective and achieve the optimal production and recovery to increase financial return from subsea assets.”

The current new technologies being developed that will help operators achieve more production and profitability from existing assets

Mike Garding said: “OneSubsea offers technologies that are both new to the market as unique products, and new in the sense that they’re gaining greater acceptance after having been under-utilized by the industry despite being well-established and field-proven to help operators reach their production and profitability goals. Subsea boosting, for example, is a field-proven technology that we feel has been under-utilized. ”

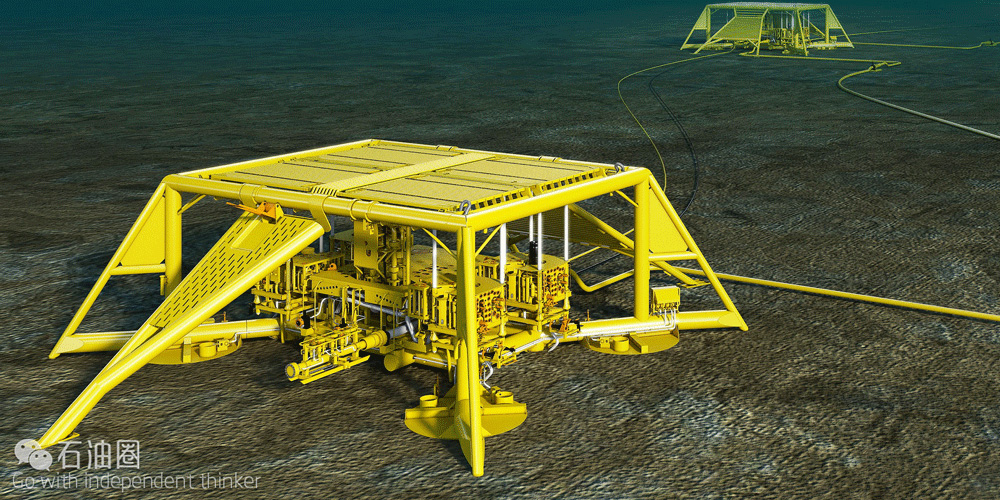

He said: “Our newest innovation is also the first of its kind. The HyFleX™ subsea tree system incorporates field-proven features of horizontal and vertical trees into a compact and flexible design that’s suitable for global applications. It is configured such that the tubing hanger and the tree are installed and recovered independently of each other because they’re situated in parallel to each other instead of in series. This unique design offers maximum installation and workover flexibility, significant CAPEX, installation, and workover savings, significantly reduced risks, and maximizes operational flexibility during the life of the field. ”

The Subsea Trees of Onesubsea

Vertical and horizontal trees are built and installed with proven technology based on extensive subsea experience and years of testing under some of the most demanding conditions. Our trees provide reliable operations in all environments, including shallow water, deep water, and ultradeep water. They have the flexibility and durability to meet specific job requirements with minimal customization. Monitoring and feedback capabilities reduce operator risk and provide data and communication for operations management.

The OneSubsea HyFleX™ Subsea Tree System provides benefits of both vertical and horizontal conventional trees. Designed so the tubing hanger and tree can be installed and recovered independently of each other, it provides functional flexibility and the ability to batch set wells, risk mitigation, and significant cost savings in field development and over the life of the field.

Providing benefits from traditional subsea tree technology with greater flexibility at lower overall cost

The HyFleX™ subsea tree system is based on existing qualified and field-proven conventional subsea tree components. However, in contrast to conventional subsea trees, the HyFleX Subsea Tree System is designed such that the tubing hanger and tree are completely independent of each other, providing unique flexibility in installation sequence and workover operations, resulting in lower CAPEX and OPEX.

Conventional horizontal subsea trees are associated with lower CAPEX due to the simple assembly where the tubing hanger is installed on top of the tree. However, workover operational costs are typically higher as the tubing hanger needs to be recovered first in order to access the tree. Conversely, conventional vertical subsea trees are configured so that the tubing hanger is installed first, followed by the tree, leading to lower workover costs, but higher CAPEX due to the larger assembly. A compromise on CAPEX versus OPEX is forced when choosing a conventional subsea tree system.

The HyFleX subsea tree system offers operators a unique economical alternative without the need for compromise. Because of the independent configuration of the tubing head spool, the tree, and the tubing hanger, the HyFleX subsea tree system components can be installed either like a conventional horizontal or vertical subsea tree. This independent design also supports the same flexibility for workover operations. The resulting CAPEX and OPEX is lower in comparison to conventional subsea tree systems, due to the reduced overall weight and the accessibility to the tree without disturbing the tubing hanger.

The HyFleX Subsea Tree System comprises three main assemblies:

1.The tubing head spool is standardized and robust, and consists of a wellhead connector and main valve body to isolate the well.

2.The tubing hanger is a conventional horizontal tree tubing hanger, and is installed in the tubing head spool.

3.The tree module interfaces with and is landed around the tubing head spool, enabling the tree’s independence from the tubing hanger. The tree module can be configured to accommodate a project’s unique equipment requirements. It contains all hydraulically actuated valves, chokes, control systems, sensors, meters, and other instrumentation, with the added benefit of enabling independent installation or retrieval of all of these items.

Key advantages of the HyFleX subsea tree system that enable cost-efficiencies and significantly improve operational performance, include:

1. Mitigation of risk as the completion, tree installation, and workover are now totally independent

2. Significant cost benefit during installation with ability to batch-set wells

3. Standardized tubing head spool with configurable tree functionality enabling shorter time to well completion.

4. Low overall lift weight due to the tubing head spool and tree module being independent of each other

5. Lowest tree workover costs due to the completion being unaffected by tree change-out and because the well may be isolated via the tubing head spool; no intervention package is required to work over the tree

6. Tree unit interchangeable throughout the life of the field

7. Based on qualified, field-proven conventional subsea tree and tooling technology

石油圈

石油圈